SEPERTI INILAH BEDUNGAN LEUWIKERIS DIBUAT

Summary

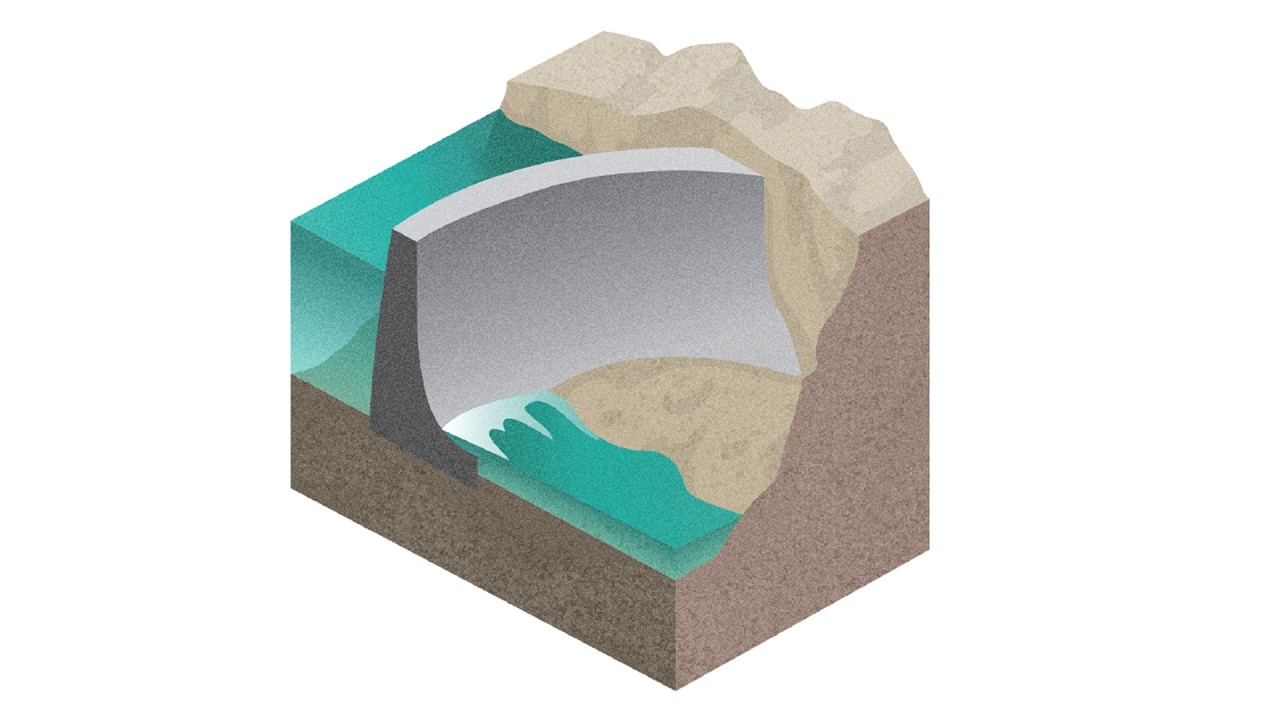

TLDRThe script discusses the construction of the Lewi Keris dam, highlighting its ability to hold back millions of cubic meters of water. It details the dam's zoning materials, with the core being a clay layer that prevents seepage. The construction process involves careful compaction with heavy machinery and the use of various materials like sand and aggregate from nearby quarries. The outermost layer, or riprap, protects the dam from erosion. The script also touches on the dam's social impact and its significance as a national engineering feat.

Takeaways

- 🌊 The dam is designed to withstand millions of cubic meters of water from the river.

- 🔍 The secret lies in the zoning of materials used in dam construction, with each zone serving a specific purpose.

- 🟤 The core of the dam consists of clay, characterized by a brown color and smooth texture, with a plasticity index over 15%.

- 🚫 Caution is needed as the clay is often accompanied by a coarser, whitish material with high permeability, which can lead to seepage.

- 🏗 The clay material is sourced from borrow areas 1.5 to 2.5 km away and compacted using heavy machinery.

- 🔧 The construction process involves multiple layers, including a fine filter zone to prevent piping and a coarse filter zone for drainage.

- 🏞 The rockfill zone provides counterweight to maintain the dam's stability against water and soil pressure, as well as seismic forces.

- 💥 Rockfill material is obtained through blasting at quarries, with specific configurations to ensure the right size for the dam's structure.

- 🌲 The random zone at the dam's base replaces some rockfill with a mix of hard and weak rocks, which can become finer due to weathering.

- 🛠 The outermost layer, the riprap, serves as a protective barrier against water impact, wave erosion, and rain, with interlocking stones installed manually.

- 🏗️ The construction of the Lewi Keris dam is a significant engineering achievement for Indonesia.

Q & A

What is the primary function of the core material in the embankment dam?

-The core material in the embankment dam serves as a waterproof layer, which is crucial for preventing the seepage of water through the dam.

What is the characteristic feature of the clay material used in the core zone?

-The clay material used in the core zone is characterized by its brown color, smooth texture, and a plasticity index (PI) of more than 15%.

Why is the material accompanying the core material referred to as 'toof'?

-The accompanying material is referred to as 'toof' because it has a slightly whitish color, coarser texture, and high permeability, which can potentially cause the core material to erode.

How far from the dam location is the borrow area for the core material located?

-The borrow area for the core material is located between 1.5 to 2.5 km from the dam site.

What machinery is used for spreading the core material during construction?

-A bulldozer of the Komatsu brand is used to spread the core material with a thickness of 30 cm.

What is the role of the fine and coarse filter zones in the dam?

-The fine and coarse filter zones act as drainage guides, directing seepage from the upstream to the downstream of the dam while preventing the fine particles from the core material from being washed out.

What are the maximum diameters for the materials used in the fine and coarse filter layers?

-The fine filter layer uses sand with a maximum diameter of 12.7 mm, while the coarse filter layer uses aggregate with a maximum diameter of 37.5 mm.

What is the purpose of the rockfill zone in the dam's structure?

-The rockfill zone serves as a counterweight to maintain the stability of the dam against water pressure, soil pressure, and seismic forces.

Where is the rockfill material sourced from and how is it obtained?

-The rockfill material is sourced from the Pangajar Quarry, which is 14 km away from the dam site, and is obtained using blasting methods with predetermined configurations.

What is the function of the random zone in the dam?

-The random zone replaces part of the rockfill material at the downstream end of the dam, providing the same function but with a mix of hard and weak rocks that can easily break down into finer particles.

How is the riprap layer installed and what is its purpose?

-The riprap layer is installed manually by workers, using stones ranging from 10 to 30 cm in size. It serves as the outermost layer of the dam, protecting it from water impact, waves, erosion, and rain.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

Why Are There No Short Arch Dams?

HUBUNGAN PERHITUNGAN TEKANAN HIDROSTATIS TERHADAP DESAIN BENDUNGAN

Etiopia-Egitto: la diga della discordia

Isère : Grand'Maison, la centrale hydroélectrique la plus puissante d'Europe

Materi 1- Tipe dan Elemen Bendungan (Pendahuluan)

TRÊS GARGANTAS: A barragem Chinesa que desafia a Natureza

5.0 / 5 (0 votes)