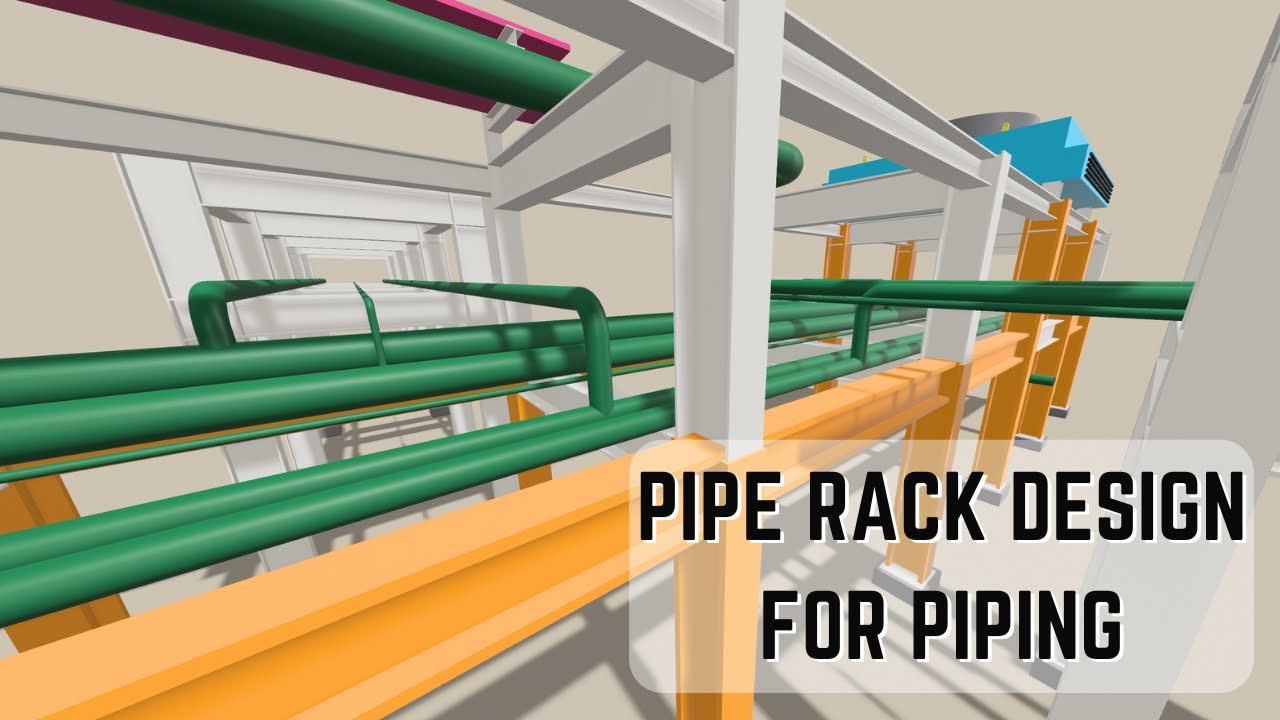

Piperack Loading | Different pipe Loads on Piperack | Piping Mantra |

Summary

TLDRThis video tutorial instructs on estimating piping loads for rack structures, crucial for civil structural design. It covers various loads like operating, thermal/friction/guide, anchor, and wind loads, without relying on stress analysis software. Detailed calculations for different pipe sizes are provided, using formulas and assumptions for load estimation. The video also touches on how to apply these loads to the pipe rack structure, offering practical insights for engineers.

Takeaways

- 🔍 The video discusses methods for estimating piping loads on rack structures without detailed stress analysis software, aiming to assist in communication between piping designers and civil engineers.

- 📐 Essential input documents for this process include preliminary layout drawings, rack cross-sections, and data on pipe weight with water and insulation.

- 💧 Operating Load is a key consideration, which includes the weight of water-filled pipes, insulation, and any valves. It varies for on-plot (ISBL) and off-plot (OSBL) pipe racks with specific minimum loads provided.

- 🔢 For pipes with diameters 12 inches and above, concentrated loads must be calculated separately, emphasizing the importance of considering pipe size in load estimation.

- 🌡️ Thermal, friction, and guide loads are calculated as 7.5% of the total operating load and are applied transversely in the horizontal plane.

- 🔗 Anchor loads are estimated based on the assumption of an eight-bay system and are applied longitudinally, with the load being the greatest cumulative anchor force from all lines over the anchor bay.

- 💨 Wind loads are determined by the projected area of the largest pipe, including insulation, and are calculated using specific codes and factors, such as basic wind speed and risk coefficients.

- 📊 The script provides a detailed calculation example for an off-plot pipe rack, demonstrating how to compute operating loads for pipes of various sizes.

- ⚙️ Thermal/Friction/Guide loads are calculated as a percentage of the operating load and are shown to vary with the pipe size and operating load.

- 📈 The video concludes with a step-by-step calculation of anchor and wind loads, illustrating how these are determined and applied to the pipe rack structure.

Q & A

What is the main topic of the video?

-The main topic of the video is about estimating piping loads on rack structures to be passed on to civil structural groups, without the need for stress analysis software.

What are the required input documents for estimating piping loads?

-The required input documents include a basic study drawing (preliminary layout), rack cross-section, and pipe weight with water and insulation.

What is the minimum operating load for on-plot pipe racks?

-The minimum operating load for on-plot pipe racks (ISBL) is 1.7 KN/square m on plan area, which is equivalent to 10.2 KN/m along the rack width.

What is the minimum operating load for off-plot pipe racks?

-The minimum operating load for off-plot pipe racks (OSBL) is 2.5 KN/square m on plan area, which is equivalent to 15 KN/m along the rack width.

What is considered as part of the operating load for pipes?

-The operating load for pipes includes the weight of the water-filled pipe, insulation weight, and if present, the weight of any valves on the rack.

How is the thermal/friction/guide load calculated?

-The thermal/friction/guide load is calculated as 7.5% of the total operating load and is applied in the transverse direction in the horizontal plane.

What is the basis for estimating anchor loads on pipe racks?

-Anchor load estimation is based on the assumption that the pipe rack comprises eight bays, with the ninth frame being the anchor bay. The load is applied in the longitudinal direction.

What is the wind load calculation based on?

-The transverse wind load on piping is based on the projected area equal to the diameter of the largest pipe, including insulation, following the 'IS 875 -1987 code of practice for the design loads other than earthquake of building and structures part 3'.

How is the test load for hydro testing lines determined?

-For hydro testing lines, the test load is considered as the pipe weight plus the full weight of water within the pipe.

What is the process for calculating the operating load for a 24-inch pipe?

-For a 24-inch pipe, the operating load is calculated by adding the bare pipe weight, the weight of the water it can hold, and the insulation weight, resulting in a total load of 442.4 Kg/m, which equates to 26 KN for a 6-meter pipe length.

Outlines

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenMindmap

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenKeywords

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenHighlights

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenTranscripts

Dieser Bereich ist nur für Premium-Benutzer verfügbar. Bitte führen Sie ein Upgrade durch, um auf diesen Abschnitt zuzugreifen.

Upgrade durchführenWeitere ähnliche Videos ansehen

5.0 / 5 (0 votes)