Digital Twin Commissioning with Emulate3D

Summary

TLDRIn this educational video, Henry Gan, a mechatronic specialist, demonstrates how to connect a virtual machine model to a PLC using Rockwell Automation's Emulate 3D software. He guides viewers through the process of selecting the IO browser, adding a PLC, and mapping PLC tags to the machine model's joints and sensors. The video also covers the importance of unit conversion between meters and millimeters for accurate data flow. Viewers learn to troubleshoot PLC code and adjust logic to prevent issues like box pile-up, making this a valuable resource for automation enthusiasts.

Takeaways

- 👋 Introduction: Henry Gan, a mechatronic specialist, introduces a tutorial on connecting a virtual machine model to a PLC using Rockwell Automation's Emulate 3D.

- 📺 Subscribe: Encourages viewers to subscribe to the ESN TV YouTube channel for automation support needs.

- 💻 Software Requirement: Users should have Emulate 3D Ultimate with a machine model ready for testing.

- 🔍 IO Browser: Demonstrates using the IO Browser toolbar in Emulate 3D to select and configure machine joints for interaction with numerical tags.

- 🔗 Device Discovery: Guides on how to find and select a PLC to connect with, using the FactoryTalk Network Browser.

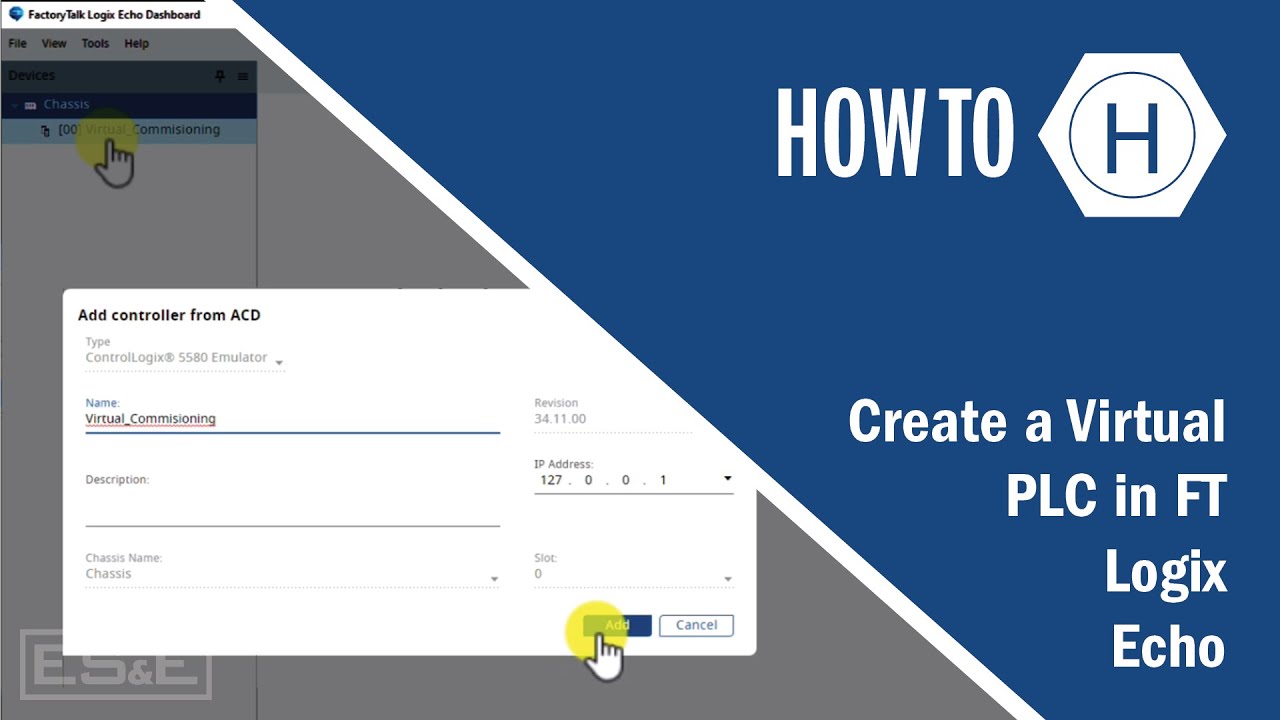

- 📊 PLC Selection: The video uses a PLC named 'Virtual Commissioning' managed by FactoryTalk Logic's Echo for the demonstration.

- 🔄 Tag Association: Shows how to link specific PLC tags to the machine model's axes and control elements like the Gantry carriage and Z beam.

- 📏 Units Conversion: Explains the need for unit conversion between millimeters (PLC) and meters (Emulate 3D) for position tags.

- 🔄 IO Connection: Describes starting the IO connection to allow data flow between the PLC and Emulate 3D for real-time interaction.

- 🛠️ Debugging: Highlights the ability to use the PLC code within the simulation to detect and fix issues, such as box pile-up on a conveyor belt.

- 👍 Engagement: Asks viewers to like the video and subscribe to the notification bell for updates on new content.

Q & A

What is the main topic of the video by Henry Gan?

-The video is about demonstrating how to connect a virtual machine model to a PLC using Rockwell Automation's Emulate 3D.

Who is the intended audience for this video?

-The video is intended for mechatronic specialists, engineers, or anyone involved in automation and PLC programming.

What is the purpose of subscribing to the ESN TV YouTube channel as mentioned in the video?

-Subscribing to the ESN TV YouTube channel ensures that viewers receive updates on all their automation support needs through the channel's content.

What software is required to be opened before starting the connection process in the video?

-You need to open Emulate 3D Ultimate with the machine model you want to test.

What is the role of the IO browser toolbar in the process described?

-The IO browser toolbar in Emulate 3D is used to select and configure the model's joints that will interact with numerical tags and tie in with PLC tags.

How does Emulate 3D identify and connect to the PLC?

-Emulate 3D uses the factory talk links network browser to find and connect to the PLC, in this case, a PLC called 'virtual commissioning'.

What are the two axes that are tied together in the video example?

-The X-axis is tied with the Gantry carriage and the Z-axis with the Z beam.

What is the function of the gripper sensor and gripper close tag in the video?

-The gripper sensor acts as a virtual proximity switch to inform the PLC that a box has been picked up. The gripper close tag is a command from the PLC to close the gripper when it is set to one, and to open it when it is zero, simulating a pneumatic device operation.

Why is a unit conversion necessary for the position tags in the video?

-A unit conversion is necessary because Emulate 3D expects values in meters, while the PLC sends tags in millimeters.

What is the benefit of starting the IO connection between the PLC and Emulate 3D?

-Starting the IO connection allows data to flow between the PLC and Emulate 3D, enabling real-time testing and detection of issues with the code, sensors, or logic.

What action should be taken if boxes start to pile up in the simulation as seen in the video?

-If boxes start to pile up, it indicates a need to adjust the PLC code to stop the process until the conveyor belt is cleared.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)