Manual Tuning with CIP Motion

Summary

TLDRIn this video, Henry Gilliland demonstrates how to manually tune a servo system using Rockwell Automation's integrated SIP motion over Ethernet IP. He explains how to adjust the system's position error scaling and manually fine-tune the axis using the manual tuning tool in Logix Designer. The video also highlights the importance of balancing performance and component lifespan, showing the effects of overtuning, and stressing the importance of knowing your system's error tolerance for optimal tuning. Viewers will learn how to achieve the best tuning without overloading the system, ensuring both efficiency and longevity.

Takeaways

- 😀 Servo motor tuning can be simplified using Rockwell Automation's integrated SIP motion over Ethernet/IP.

- 😀 Auto-tune in Rockwell's Studio 5000 Logix Designer can optimize servo performance automatically.

- 😀 Manual tuning allows for fine-tuning of servo systems and adjustments to improve axis performance.

- 😀 The scaling of position error can be adjusted to magnify the following error for better visualization.

- 😀 A simple index move to 140 mm at 80 mm/s can help reduce following error during manual tuning.

- 😀 System bandwidth is the main parameter adjusted in manual tuning to reduce following error.

- 😀 Small, incremental adjustments to system bandwidth should be made to prevent destabilization.

- 😀 Over-tuning the servo system by increasing bandwidth too much can lead to catastrophic destabilization and resonance.

- 😀 If the system becomes over-tuned, the solution is to reduce the system bandwidth to restore stability.

- 😀 The optimal tuning should be based on the specific application’s error tolerance, ensuring efficiency and minimal component stress.

Q & A

What is the main focus of the video?

-The main focus of the video is teaching how to manually tune servo motors using Rockwell Automation's integrated SIP motion over Ethernet IP, focusing on adjusting the system bandwidth to minimize following error and optimize performance.

What is the first step in tuning a servo motor manually?

-The first step is adjusting the scaling of the position error to magnify it, allowing a more detailed view of the error as the axis moves.

Why is it important to adjust the position error scaling?

-Adjusting the position error scaling is important because it allows you to see small changes in the error, which helps in making precise adjustments to the servo system.

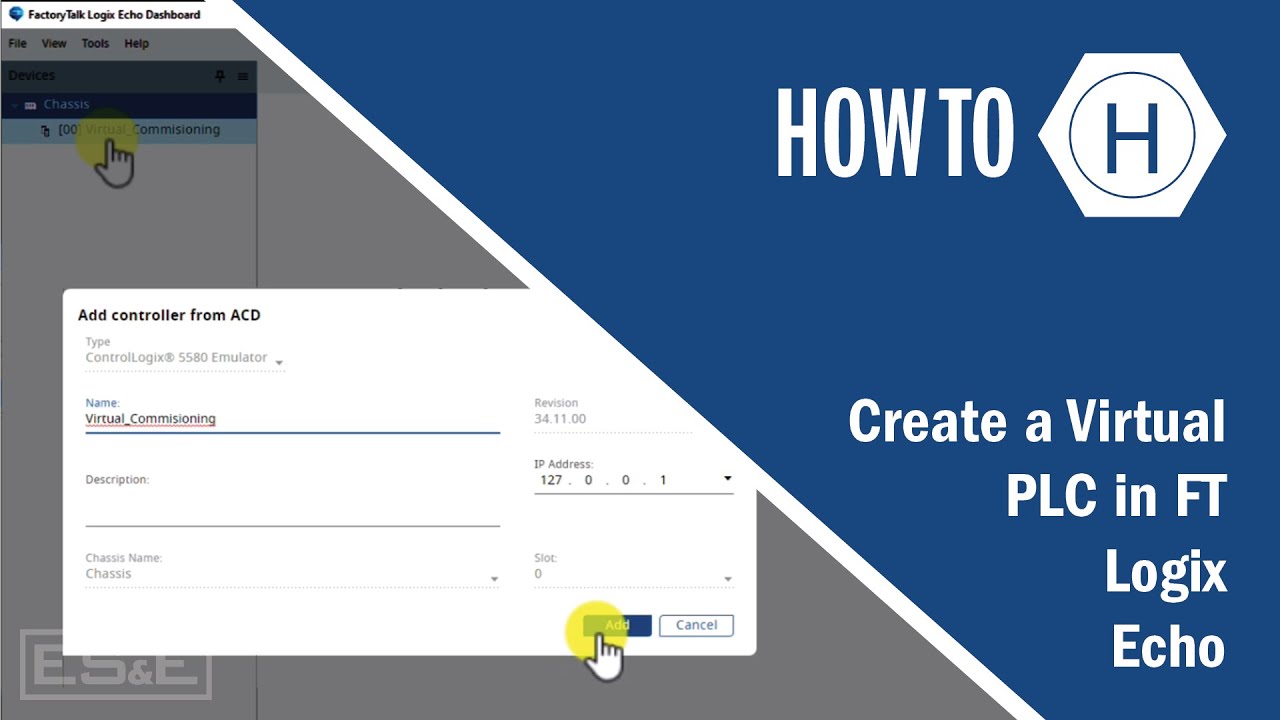

How can you access the manual tuning window in Rockwell's Studio 5000 Logix Designer?

-You can access the manual tuning window by right-clicking on the axis or by going to the axis properties within the software.

What is the role of the system bandwidth in manual tuning?

-The system bandwidth controls the following error. Increasing the system bandwidth generally reduces the following error, but excessive bandwidth can lead to destabilization of the system.

What happens when the system bandwidth is increased too much?

-When the system bandwidth is increased too much, it causes catastrophic destabilization, often manifesting as severe and persistent resonance. This can also be accompanied by an audible hum or buzz from the motor.

What should be done if resonance occurs due to over-tuning?

-If resonance occurs, the system bandwidth should be reduced to eliminate the destabilization and restore stability to the system.

How can you determine the best tuning for a specific application?

-The best tuning for a specific application is determined by understanding the error tolerance required for that application. Adjusting the tuning to fit the tolerance ensures optimal performance without over-stressing the system.

Why is it important to know the error tolerance of an application before tuning?

-Knowing the error tolerance is crucial because it ensures that the servo system is tuned within the necessary precision limits, preventing over-tuning and reducing unnecessary strain on electrical and mechanical components.

What are the risks of over-tuning a servo system?

-Over-tuning a servo system can lead to excessive wear on components, instability, and resonance, which can negatively impact both performance and the lifespan of the system.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)