What is Operations Management?

Summary

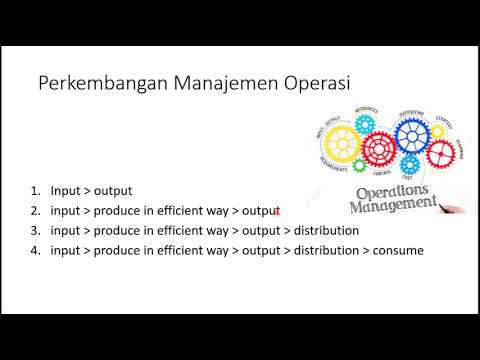

TLDRThis script delves into the concept of operations management, highlighting its role in transforming inputs into outputs, both in goods and services. It uses the car industry as an example, illustrating how materials like metal are shaped into components by machines operated by humans, ultimately becoming part of a finished car. The script emphasizes the importance of improving these transformation processes through strategies like total quality management, Kanban, and total productive maintenance.

Takeaways

- 🚀 Operations management is integral to the production of goods and services, providing insight into the process from inputs to outputs.

- 🔍 The 'black box' of production processes is opened by operations management, revealing the transformation from raw materials to finished products.

- 📦 Inputs in operations management include material, manpower, and machines, all of which are essential for the production process.

- 🔧 Outputs are the end results of the production process, which can be physical goods or services.

- 🏭 An example from the car industry illustrates how material, such as metal, is transformed into a finished component through the use of machines and operators.

- 🔑 The transformation process is a central focus of operations management, where the goal is to improve efficiency and effectiveness.

- 💡 Concepts like total quality management, Kanban, and total productive maintenance are tools used to enhance transformation processes.

- 🛠️ The role of the machine operator is highlighted, showing the human element in the mechanized production process.

- 🔄 The transformation of raw materials into components, such as the metal press example, is a key step in the production of goods.

- 🔑 The finished component, assembled on a car, represents the output of the production process, demonstrating the tangible result of operations management.

- 🌟 Continuous improvement of the production process is a fundamental aspect of operations management, driving the industry towards better quality and productivity.

Q & A

What is Operations Management?

-Operations Management is the management of the entire process that transforms inputs into outputs, where outputs can be physical goods or services.

What are the main components of the production process in Operations Management?

-The main components are inputs, which include material, manpower, and machines, and the transformation process that turns these inputs into outputs.

Can you give an example of an input in the car industry?

-An example of an input in the car industry is the material, such as metal, which is used to create finished components for cars.

What is the role of a machine operator in the production process?

-A machine operator is responsible for operating machinery, such as a press, to reshape the material into a finished component.

What is the significance of the transformation process in Operations Management?

-The transformation process is significant as it is the mechanism through which inputs are converted into outputs, which are the final products or services.

What is the 'black box' mentioned in the script?

-The 'black box' refers to the production process, which is often not fully understood or visible to those outside of operations management.

How can Operations Management improve transformation processes?

-Improvement can be achieved through concepts such as Total Quality Management, Kanban, or Total Productive Maintenance.

What is Total Quality Management and how does it relate to Operations Management?

-Total Quality Management (TQM) is a management approach focused on quality control and continuous improvement, which can be applied to enhance the efficiency and effectiveness of transformation processes in Operations Management.

What is Kanban and how can it be used in Operations Management?

-Kanban is a scheduling system used to improve production efficiency and minimize waste by controlling the release of work items to the production process.

What is Total Productive Maintenance and its purpose in Operations Management?

-Total Productive Maintenance (TPM) is a preventive maintenance program aimed at maximizing equipment efficiency, reducing downtime, and improving overall productivity in the production process.

How does the example of the car industry illustrate the concept of Operations Management?

-The car industry example demonstrates how material (metal) is transformed into a finished component (car part) through the operation of a machine (press) by a machine operator, highlighting the transformation process in Operations Management.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)