Fused Deposition Modeling (FDM) Technology

Summary

TLDRFused Deposition Modeling (FDM) is a 3D printing process that uses thermoplastic materials to create both prototypes and end-use parts. The process involves slicing 3D CAD data into layers, which are then built up layer by layer using a heated extrusion nozzle. This method delivers high strength-to-weight ratios and is suitable for functional prototypes, concept models, and low-volume production. Industries such as aerospace, automotive, and medical rely on FDM for durable, functional parts. FDM parts are often finished for smoothness and visual appeal, with options like hand sanding and cosmetic painting.

Takeaways

- 😀 FDM (Fused Deposition Modeling) is an additive manufacturing process that uses thermoplastic materials to create prototype and end-use parts.

- 😀 FDM is known for its ability to produce accurate feature details and offers an excellent strength-to-weight ratio.

- 😀 The technology is ideal for concept models, functional prototypes, manufacturing aids, and low-volume end-use parts.

- 😀 FDM begins by 'slicing' 3D CAD data into layers, which are then used to construct the part layer by layer on a build platform.

- 😀 Thermoplastic material and support material are used to form each cross-section of the part, similar to how a hot melt glue gun works.

- 😀 The extrusion nozzle moves in a horizontal X-Y plane while the build platform moves down to create the part layer by layer.

- 😀 After the part is finished, it is removed from the build platform and cleaned of its support material.

- 😀 Raw FDM parts have visible layer lines, but post-processing services like sanding, assembly, and painting can smooth the surface.

- 😀 FDM parts are made with production-grade thermoplastics such as ABS, Polycarbonate, and Ultem, making them durable and functional.

- 😀 FDM is widely used across industries including aerospace, automotive, industrial, commercial, and medical applications.

Q & A

What is Fused Deposition Modeling (FDM)?

-Fused Deposition Modeling (FDM) is an additive manufacturing process that uses thermoplastic materials to produce prototype and end-use parts by building them layer by layer.

What types of parts are ideal for FDM technology?

-FDM is ideal for creating concept models, functional prototypes, manufacturing aids, and low-volume end-use parts.

How does the FDM process begin?

-The FDM process starts with 'slicing' 3D CAD data into layers, which are then transferred to a machine that constructs the part layer by layer.

What materials are used in FDM manufacturing?

-FDM uses thin thread-like spools of thermoplastic materials, as well as support materials, to build each layer of the part.

How does the FDM machine extrude material?

-The FDM machine extrudes material through dual heated nozzles, similar to a hot melt glue gun. These nozzles precisely lay down both the support and thermoplastic materials onto the previous layers.

What movement does the extrusion nozzle make during the FDM process?

-The extrusion nozzle moves in a horizontal X-Y plane, while the build platform moves down as the part is constructed layer by layer.

What happens after the part is finished in FDM?

-Once the part is finished, it is removed from the build platform and cleaned of its support material.

What is the appearance of raw FDM parts?

-Raw FDM parts typically have visible layer lines due to the layer-by-layer construction process.

How can the appearance of FDM parts be improved?

-FDM parts can be enhanced through finishing options like hand sanding, assembly, and cosmetic painting, which help create smooth, even surfaces.

What types of thermoplastics are used in FDM parts?

-FDM parts are made using production-grade thermoplastics such as ABS, Polycarbonate, and Ultem, which provide both functionality and durability.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

3D Printing Materials Explained: Compare FDM, SLA, and SLS

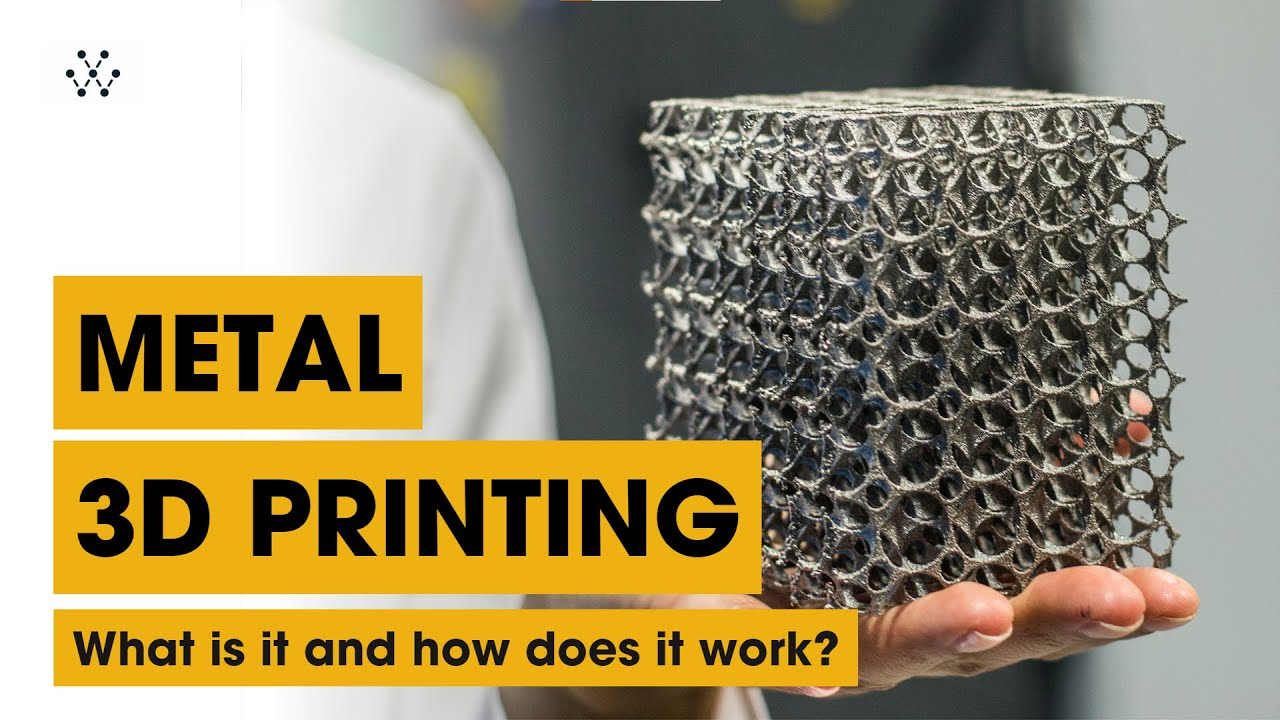

METAL 3D PRINTING | What is it and how does it work ?

Blender 3D Tutorial Membuat Karakter Game Amoung Us! 3D Modeling, (Pemula) Blender 2.90

Transparent FDM 3D Prints are Clearly Stronger!

what 3d printing software to use

Types of 3D Printers - 11 Different Types of 3D Printers - Introduction to 3D Printing

5.0 / 5 (0 votes)