The Trainer #67 - When Fuel Trims Won't Trim

Summary

TLDRThis trainer episode explains how to diagnose system-lean and system-rich generic DTCs by focusing on fuel control — how the ECM uses oxygen sensor feedback and fuel trims to keep the air–fuel ratio centered. It walks technicians through key checks: review freeze-frame data, perform a road-test with logged PIDs, distinguish MAF vs. speed-density systems, and hunt for vacuum leaks with a smoke machine. The host emphasizes fuel delivery (pressure and volume), injector condition, sensor wiring, and ethanol/flex-fuel issues — even demonstrating a quick jar test for alcohol content — offering practical, step-by-step troubleshooting tips.

Takeaways

- 😀 Understanding PIO 171 & PIO 174: These codes indicate 'system lean' and 'system rich' conditions, where the ECM cannot maintain the correct air-fuel mixture.

- 😀 Fuel Control: The ECM establishes fuel control when the oxygen sensor provides consistent feedback, helping maintain a correct air-fuel ratio. Any deviation from this range signals the need for corrections.

- 😀 Key Factors for Lean/Rich Conditions: Miscalculated fuel trims, faulty injectors, and incorrect fuel pressure can trigger system lean or system rich codes.

- 😀 Importance of Freeze Frame Data: Always check freeze frame data to understand the specific operating conditions when the code was set. This can reveal important clues for diagnosis.

- 😀 Vacuum Leaks and MAF Sensors: Both can cause unmetered air to enter the engine, leading to incorrect fuel calculations and triggering system lean codes.

- 😀 Regular Road Tests: Perform tests under varying conditions (idle, cruising, wide-open throttle) to monitor fuel trims and better understand engine behavior.

- 😀 Mass Airflow Sensor (MAF) Accuracy: Ensure the MAF sensor is providing accurate readings by performing a volumetric efficiency test and checking sensor power and ground connections.

- 😀 Alcohol Content in Fuel: Flex-fuel vehicles can misreport fuel type, especially when switching between ethanol and gasoline, leading to inaccurate ECM fuel mixture calculations.

- 😀 Diagnosing System Lean Conditions: Start by checking the fuel delivery system (injectors, fuel volume, pressure) and addressing any potential vacuum leaks or sensor inaccuracies.

- 😀 Diagnosing System Rich Conditions: Similar to diagnosing system lean, but focus on potential causes of excess fuel delivery, such as faulty injectors or incorrect sensor data.

- 😀 Fuel Delivery System: Routine checks of both fuel pressure and volume are critical, especially when diagnosing drivability issues under higher loads or speeds.

Q & A

What are the PIO 171 and PIO 174 DTCs, and what do they indicate?

-The PIO 171 and PIO 174 DTCs are generic diagnostic trouble codes indicating a 'system lean' condition. These codes set when the engine control module (ECM) detects that the air-fuel mixture is too lean, meaning there is too much air and not enough fuel in the mixture, or too rich, meaning too much fuel and not enough air.

How does the ECM handle a lean or rich system condition?

-The ECM tries to correct a lean or rich condition by adjusting the fuel trim. For a lean condition, it adds fuel to compensate for the excess air. For a rich condition, it subtracts fuel to reduce the excess fuel. If the ECM is unable to bring the air-fuel mixture back to normal after multiple corrections, the PIO 171 or PIO 174 codes will set.

What is the definition of fuel control in relation to the ECM?

-Fuel control, as defined by the script, is established when the ECM is able to maintain a correct air-fuel ratio by adjusting the fuel based on feedback from the oxygen sensor. The sensor should oscillate around a specific value (0.45 millivolts), indicating that the ECM is maintaining the proper fuel mixture.

Why is it important to understand the ECM’s diagnostic criteria for these codes?

-Understanding the ECM's diagnostic criteria is crucial because it helps technicians know exactly how the ECM determines when to set the codes. This knowledge allows technicians to construct tests that mimic the ECM's logic, making it easier to identify the root cause of the issue.

What role does freeze frame data play in diagnosing lean or rich system codes?

-Freeze frame data provides crucial information about the conditions under which the code was set, such as engine temperature, load, and fuel trims. Reviewing this data helps technicians understand whether the problem occurred at idle, under load, or during a cold start, providing valuable insights for diagnosis.

What is the significance of performing a test drive when diagnosing these codes?

-A test drive helps gather data under various driving conditions (idle, highway cruising, and wide-open throttle). This allows technicians to monitor fuel trims and other key parameters in real time, which can highlight potential issues with the fuel system, sensors, or vacuum leaks.

What is the difference between a speed density system and a mass airflow system?

-A speed density system relies on inputs from various sensors, primarily the manifold absolute pressure (MAP) sensor, to calculate the amount of air entering the engine. In contrast, a mass airflow (MAF) system directly measures the amount of air entering the engine, providing the ECM with an exact value to calculate fuel requirements more accurately.

How can a faulty mass airflow sensor affect fuel control and lead to system lean or rich codes?

-A faulty mass airflow sensor can misreport the amount of air entering the engine, causing the ECM to calculate incorrect fuel requirements. This can lead to improper air-fuel ratios, triggering system lean or system rich codes. Contaminated sensors or damaged sensor components can produce skewed readings.

What is 'unmetered air' and how does it affect the ECM's fuel calculations?

-Unmetered air refers to air entering the engine without passing through the mass airflow sensor. This can occur due to vacuum leaks, torn intake boots, or cracked gaskets. Since the ECM doesn’t account for this additional air, the air-fuel mixture becomes lean, and the system compensates by adding fuel, which can trigger a system lean code.

What common issue related to fuel could cause a system lean or system rich code, and how can it be diagnosed?

-A common issue that could cause system lean or system rich codes is a fuel delivery problem, such as low fuel pressure, faulty injectors, or a clogged fuel filter. Diagnosing this involves checking both fuel pressure and fuel volume, as low fuel volume under load can cause these codes to set, even if fuel pressure seems normal.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

Bagian Sistem Injeksi Honda Beat PGM FI

Pengenalan Dasar Engine Management System (EMS) di Kendaraan EFI - Sensor, ECM, dan Aktuator ‼️

Short Term and Long Term Fuel Trims Explained

What Your Black Exhaust Smoke Is Trying To Tell You?

CUMMINS Celect system

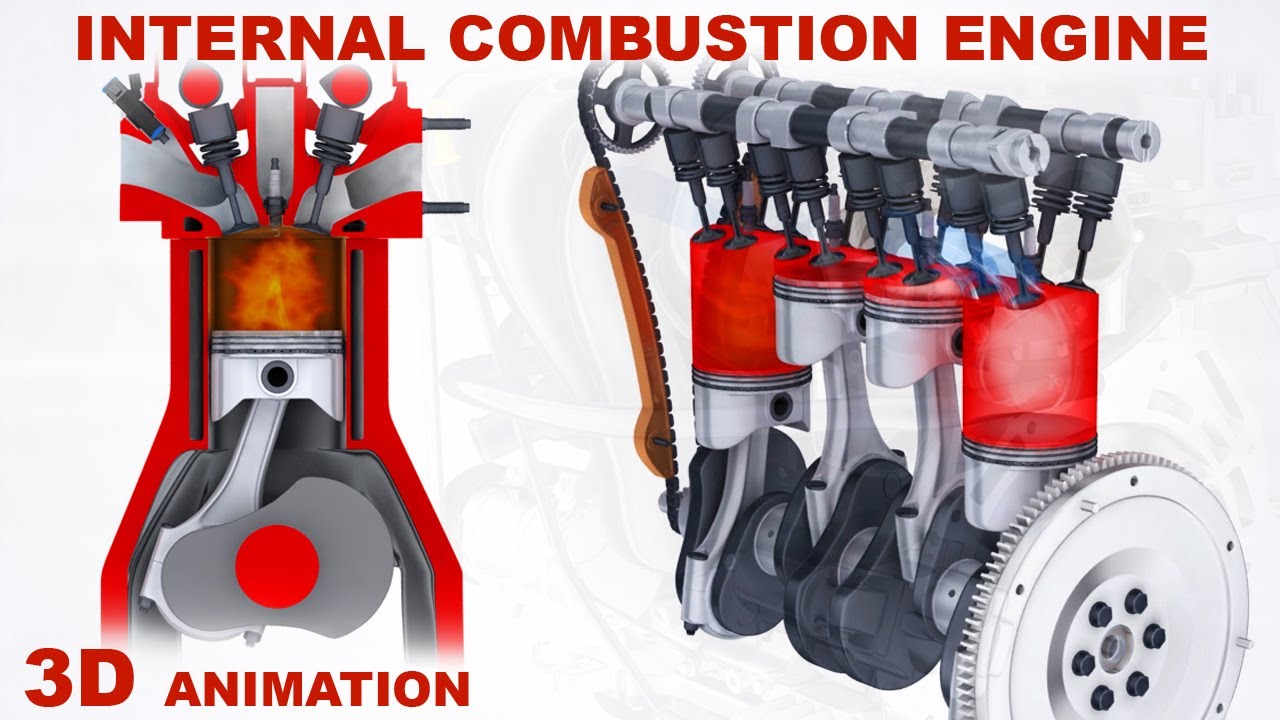

How car engine works? / 4 stroke internal combustion engine (3D animation)

5.0 / 5 (0 votes)