CUMMINS Celect system

Summary

TLDRThe ISM engine’s advanced fuel system utilizes electronic control for precise fuel metering and injection timing. Key components include the ECM, positive displacement fuel pump, and the highly efficient Fleetguard Stratapore filter. The system optimizes engine performance, improves fuel economy, and reduces emissions. Full-time double pulse injection, introduced in the ISM engine, allows precise control over fuel flow, enhancing power output and lowering emissions. The ECM dynamically manages fueling and timing, ensuring cleaner combustion and more responsive acceleration, while the integrated components work together for maximum fuel efficiency and protection against contaminants.

Takeaways

- 😀 The ISM engine features the most advanced fuel control system, utilizing electronics for precise fuel metering and injection timing.

- 😀 The ECM (Engine Control Module) manages engine fueling and injection timing based on sensor inputs to optimize performance, fuel economy, and reduce emissions.

- 😀 The ECM cooling plate contains a fuel tube that circulates fuel to cool the ECM, preventing overheating.

- 😀 The fuel pump is a positive displacement gear-driven pump that operates at approximately 150 psi, providing consistent pressure to injectors.

- 😀 The fuel system uses a Fleetguard Stratapore fuel-water separator filter, which removes 98.7% of particles 10 microns or larger, ensuring cleaner fuel.

- 😀 The Stratapore filter offers improved filtration, water removal, contaminant capacity, and a longer service life compared to traditional filters.

- 😀 The water-in-fuel sensor alerts the driver when the filter requires draining, providing real-time feedback for maintenance.

- 😀 The ISM injector offers increased fuel flow to meet higher power demands and lower emissions, with full-time double pulse injection for precise control.

- 😀 The ECM controls fuel injection timing by managing when the injector control valve opens and closes, adjusting the amount of fuel injected.

- 😀 The injector system features a hydraulic link between the timing plunger and metering plunger, ensuring high-pressure fuel injection for cleaner combustion and improved performance.

Q & A

What role does the ECM play in the ISM engine's fuel system?

-The ECM (Engine Control Module) controls fuel metering and injection timing, optimizing engine performance, fuel economy, and reducing exhaust emissions by processing inputs from sensors and switches.

How does the ECM cooling plate help maintain engine performance?

-The ECM cooling plate contains an internal fuel tube that circulates fuel to cool the ECM, preventing overheating. Isolators help prevent heat transfer from the engine to the ECM.

What is the purpose of the positive displacement gear-driven fuel pump?

-The positive displacement gear-driven fuel pump is responsible for maintaining a relatively constant fuel pressure (about 150 psi) to the injectors, ensuring stable fuel flow to the engine.

How does the Fleetguard Stratapore fuel filter contribute to fuel system protection?

-The Stratapore fuel filter is highly efficient, removing 98.7% of particles 10 microns or larger, and offers better water removal, higher contaminant capacity, and longer service life compared to traditional filters.

What is the function of the water-in-fuel (WIF) sensor in the fuel filter?

-The WIF sensor detects when the water level in the filter reaches a certain threshold and sends a signal to the ECM, which activates a maintenance alert for the operator to drain the filter.

What improvements does the new ISM injector provide over previous models?

-The ISM injector offers increased fuel flow to meet higher power and lower emission demands, as well as enhanced control over fuel metering, which improves engine performance and response.

How does the full-time double pulse injection system work on the ISM engine?

-The full-time double pulse injection system meters fuel more precisely by adjusting the timing and amount of fuel injected, resulting in better engine acceleration and cleaner combustion.

What is the significance of the timing and metering plungers in the fuel injection process?

-The timing and metering plungers control the flow and pressure of fuel into the injectors. The ECM adjusts the timing to optimize the amount of fuel injected, improving engine efficiency and reducing emissions.

What happens when the metering chamber reaches approximately 5,000 PSI?

-When the metering chamber reaches 5,000 PSI, the needle valve begins to lift, allowing fuel to be injected into the combustion chamber. The pressure builds until injection is completed.

Why is the pressure relief valve important in the ISM injector system?

-The pressure relief valve helps reduce high-pressure spikes during injection, preventing damage to the injector system and ensuring smoother fuel flow for more efficient combustion.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

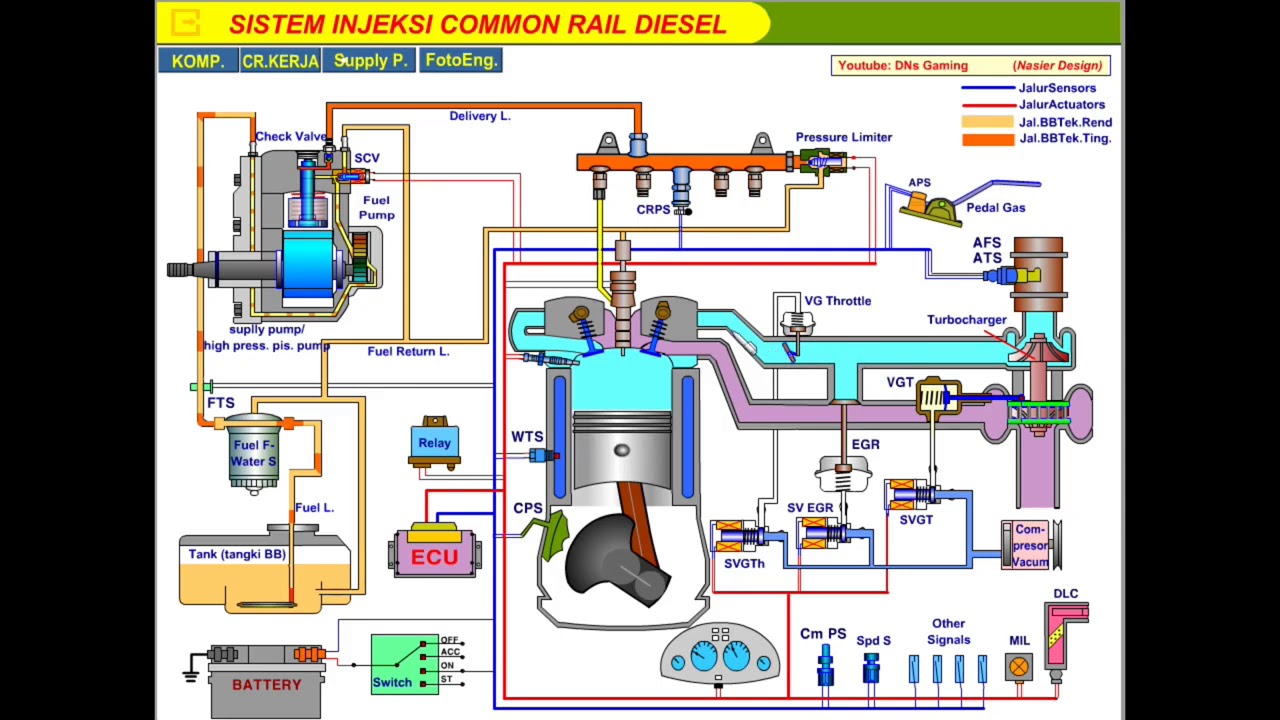

cara kerja bahan bakar diesel (Tipe common rail)

Sistem Bahan Bakar Injeksi (Fungsi Sistem dan Komponen-komponennya)

Cukup 3 Menit Untuk Memahami Sistem Injeksi Pada Sepeda Motor

Bagian Sistem Injeksi Honda Beat PGM FI

SISTEM INJEKSI, Macam-macam Sistem Injeksi I Bahasa Indonesia

Common Rail Diesel, Inovasi Jenius Yang Bikin Mesin Diesel Semakin Irit

5.0 / 5 (0 votes)