What is Just-in-Time (JIT) Inventory Management?

Summary

TLDRJust-in-Time (JIT) inventory is a strategy where materials are delivered right as production is scheduled, minimizing on-hand inventory and waste. This method is ideal for businesses that follow a make-to-order model. While it reduces costs, warehouse space, and waste, it also means that companies must meticulously plan production and accurately forecast demand. Any unexpected demand spikes could disrupt operations. When executed well, JIT enhances efficiency, lowers costs, and boosts profitability by aligning stock levels with production needs.

Takeaways

- 😀 Just-in-Time (JIT) inventory is a strategy that aligns raw material delivery with specific production cycles.

- 😀 The goal of JIT is to ensure materials arrive only as production is scheduled, reducing excess stock.

- 😀 JIT minimizes inventory on hand, aiming to reduce waste while maintaining high-volume production.

- 😀 This strategy works well for businesses that use a make-to-order model, where products are made as needed.

- 😀 JIT may not be suitable for businesses with unpredictable demand since it only keeps enough stock to meet current orders.

- 😀 To be effective, businesses using JIT must meticulously plan production, ensure accurate demand forecasting, and fine-tune supply chain visibility.

- 😀 Successful implementation of JIT reduces inventory costs, minimizes warehouse space needs, and improves operational efficiency.

- 😀 The key benefits of JIT include reduced waste and increased business profitability.

- 😀 JIT inventory management requires a close relationship with suppliers to ensure timely delivery of materials.

- 😀 Businesses need to have strong control over their supply chain to avoid disruptions in production under a JIT system.

Q & A

What is Just-in-Time (JIT) inventory management?

-Just-in-Time (JIT) is an inventory management strategy where raw material deliveries are timed to align with specific production cycles, ensuring that materials arrive only when they are needed and in the right amount.

How does JIT inventory management help reduce waste?

-JIT minimizes waste by ensuring that only the necessary amount of inventory is kept on hand, preventing overstocking and reducing excess materials that might go unused or expire.

What is the key goal of JIT inventory management?

-The main goal of JIT inventory management is to achieve high-volume production while minimizing the amount of inventory on hand, thereby reducing costs and waste.

For which type of business model does JIT work best?

-JIT works particularly well for businesses that follow a make-to-order model, where products are made only after receiving customer orders, reducing the need for large inventories.

What is the downside of using a JIT inventory strategy?

-The downside of JIT is that businesses may struggle to meet unexpected demand since the system is designed to keep only enough stock to meet scheduled production needs.

What does a business need to ensure when using JIT inventory management?

-To successfully implement JIT, businesses need to meticulously plan production, fine-tune supply chain visibility, and ensure that demand forecasting is accurate to avoid stockouts or production delays.

How does JIT inventory management affect warehouse space?

-JIT reduces warehouse needs since businesses keep only the inventory required for immediate production, minimizing the amount of storage space needed for excess goods.

How can JIT improve business profitability?

-JIT can increase profitability by lowering inventory costs, minimizing warehouse space requirements, improving operational efficiencies, and reducing waste, all of which contribute to cost savings.

What role does demand forecasting play in JIT inventory management?

-Accurate demand forecasting is critical in JIT inventory management, as it helps businesses plan production schedules and manage raw material delivery to avoid production disruptions or excess inventory.

What are the main benefits of a successful JIT strategy?

-A successful JIT strategy leads to lower inventory costs, reduced warehouse space requirements, increased operational efficiency, minimized waste, and improved overall profitability.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

[PRESENTASI] TEKNIK PERSEDIAAN METODE JIT (JUST IN TIME) DAN EOQ (ECONOMIC ORDER QUANTITY)

Just In Time JIT Definition Investopedia

Just In Time - How Toyota, McDonalds and Apple Use Just In Time - With Examples

What is Inventory Control? Explained in 9 minutes

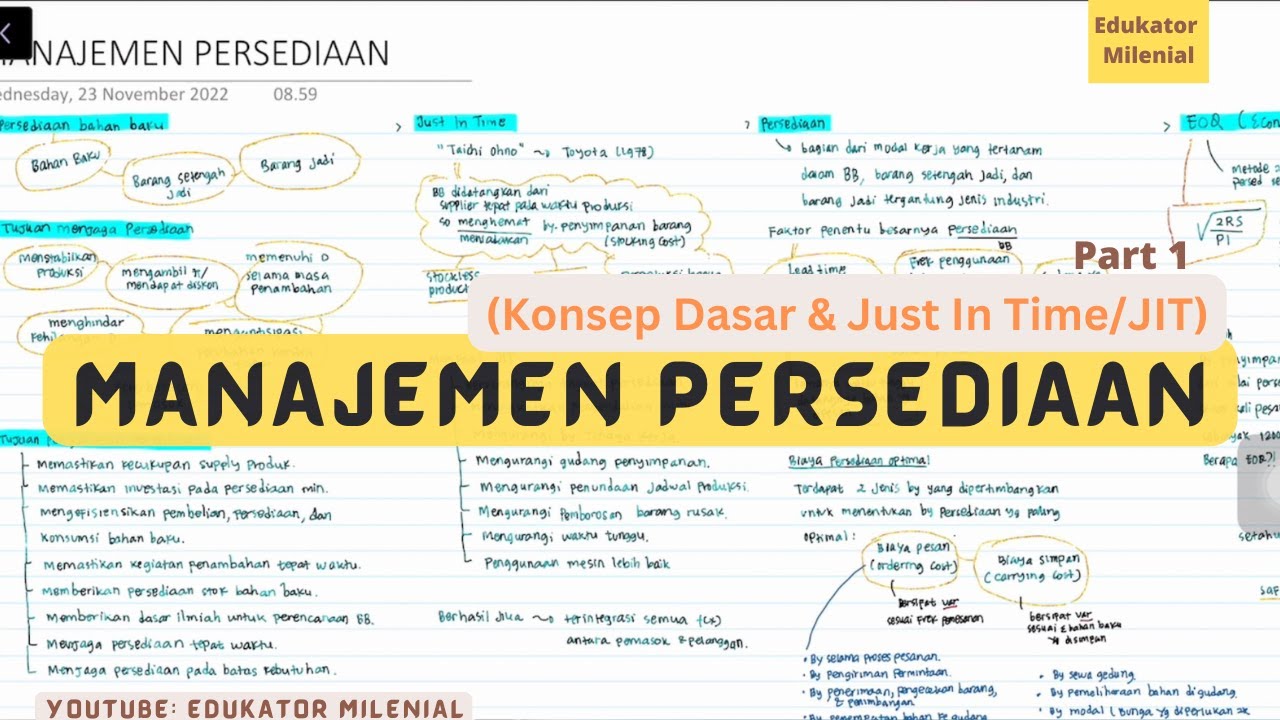

Manajemen Persediaan (Just In Time - JIT)

E learning : Manajemen Operasional - Sesi 8, Manajemen Persediaan | by Siti Mariam

5.0 / 5 (0 votes)