How to Replace Sway Bar Bushings and End Links

Summary

TLDRIn this video, ChrisFix demonstrates how to replace sway bar end links and body bushings to refurbish the sway bar system. He walks viewers through diagnosing issues with the sway bar, removing old parts, and installing new ones. Key steps include unbolting the sway bar end links, replacing corroded bushings, and using silicone for smoother installation. He also offers tips on preventing rust, adjusting bushings, and ensuring everything is properly torqued. This DIY tutorial is perfect for anyone looking to maintain or refurbish their vehicle's suspension system for better performance and safety.

Takeaways

- 😀 Sway bars reduce body roll during turns and on uneven roads, improving vehicle stability.

- 😀 Replacing both the sway bar end links and body bushings is a straightforward maintenance task.

- 😀 Rusty and corroded components, such as sway bar bushings, can cause difficulty during removal and replacement.

- 😀 Using a breaker bar can help loosen rusted nuts that are hard to remove with a regular ratchet.

- 😀 It's important to check both the driver's and passenger's side when replacing sway bar components, as both sides usually require attention.

- 😀 Penetrating fluid can help loosen rusted parts, but sometimes, cutting tools or a hammer may be necessary for stubborn components.

- 😀 New sway bar bushings should be installed with high-temp silicone to prevent squeaking and to protect rubber from damage caused by petroleum-based grease.

- 😀 Using a block of wood and a jack can help support the sway bar during installation, especially when working alone.

- 😀 Applying removable Loctite on bolts can prevent them from loosening due to vibrations.

- 😀 When installing sway bar end links, ensure the bushings and washers are installed in the correct order and facing the correct direction to avoid issues.

- 😀 The bushings should be tightened until they begin to expand, but not overly compressed, to ensure proper performance and prevent damage.

Q & A

What is the primary function of a sway bar in a vehicle?

-The sway bar reduces body roll on uneven roads and during turns. It acts as a spring that forces the inside tire down during a turn, improving vehicle handling.

What tools are required to replace sway bar end links and bushings?

-You will need a breaker bar, ratchet, penetrating fluid, hammer, block of wood, jack, and possibly a vice grip. A 16mm wrench is also necessary for some bolts.

Why does the sway bar need to be refurbished?

-The sway bar needs to be refurbished to replace worn-out or corroded components, such as end links and bushings, which can affect the handling and safety of the vehicle.

What should you do if the sway bar components are rusted and difficult to remove?

-If the sway bar components are rusted, you should apply penetrating fluid and use a hammer to loosen them. In some cases, cutting or using a vice grip may be necessary.

What is the significance of using silicone during the installation of new bushings?

-Silicone helps prevent squeaking by lubricating the bushings. It’s important to use silicone rather than petroleum-based grease, as petroleum can damage rubber bushings.

How do you install the new sway bar body bushings?

-To install the new body bushings, slide them onto the sway bar in the correct orientation. Use a bit of silicone for lubrication and ensure they fit snugly in the body mount bracket.

What are the proper torque specifications for the sway bar body mount bolts?

-The body mount bolts should be torqued to 25-34 foot-pounds to ensure they are securely fastened without being overtightened.

How do you install the sway bar end links?

-For the end links, first slide a washer onto the long bolt with the cup facing down, then add a bushing with the beveled lip facing downward. Assemble the other side with a washer, bushing, and nut, ensuring the bushings face inward and the washers cup the bushings.

Why is it important to compress the bushings during end link installation?

-Compressing the bushings ensures they are properly seated. However, they should not be compressed too much, as this could lead to damage. Tighten until the bushings begin to show slight compression, then stop.

What can you do if you don’t have enough ground clearance to work on the sway bar system?

-If your vehicle lacks ground clearance, you can use a jack to lift the car or perform the work with the wheels on the ground if the clearance is sufficient.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

This is How a Rear Sway Bar Will Unlock More Speed | Mk7 GTI

Your RD1 CRV Making clunking Noises? CHANGE THESE PARTS !

Snapped coil spring replacement HYUNDAI TUCSON #hyundai #tucson #snappedcoilspring

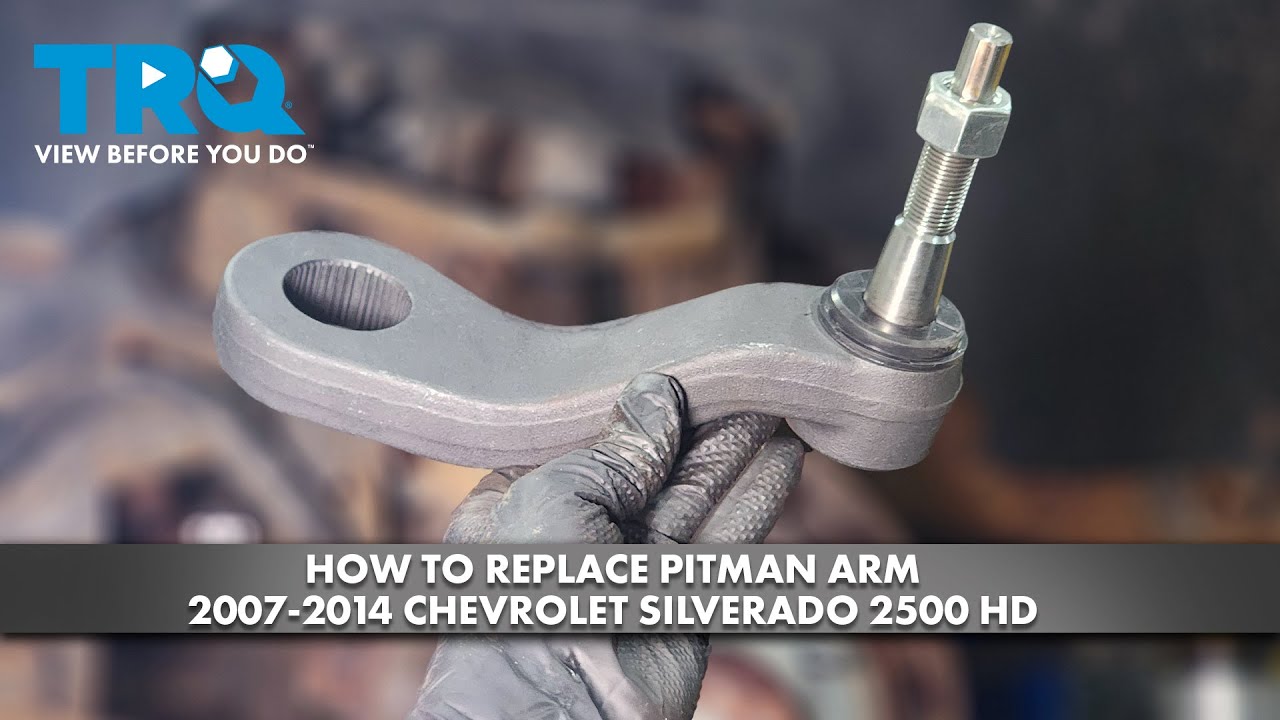

How to Replace Pitman Arm 2007-2014 Chevrolet Silverado 2500 HD

How to Replace Leaf Springs and Lift your Truck

Are Aftermarket Sway Bars Worth It?

5.0 / 5 (0 votes)