Charpy Impact Test

Summary

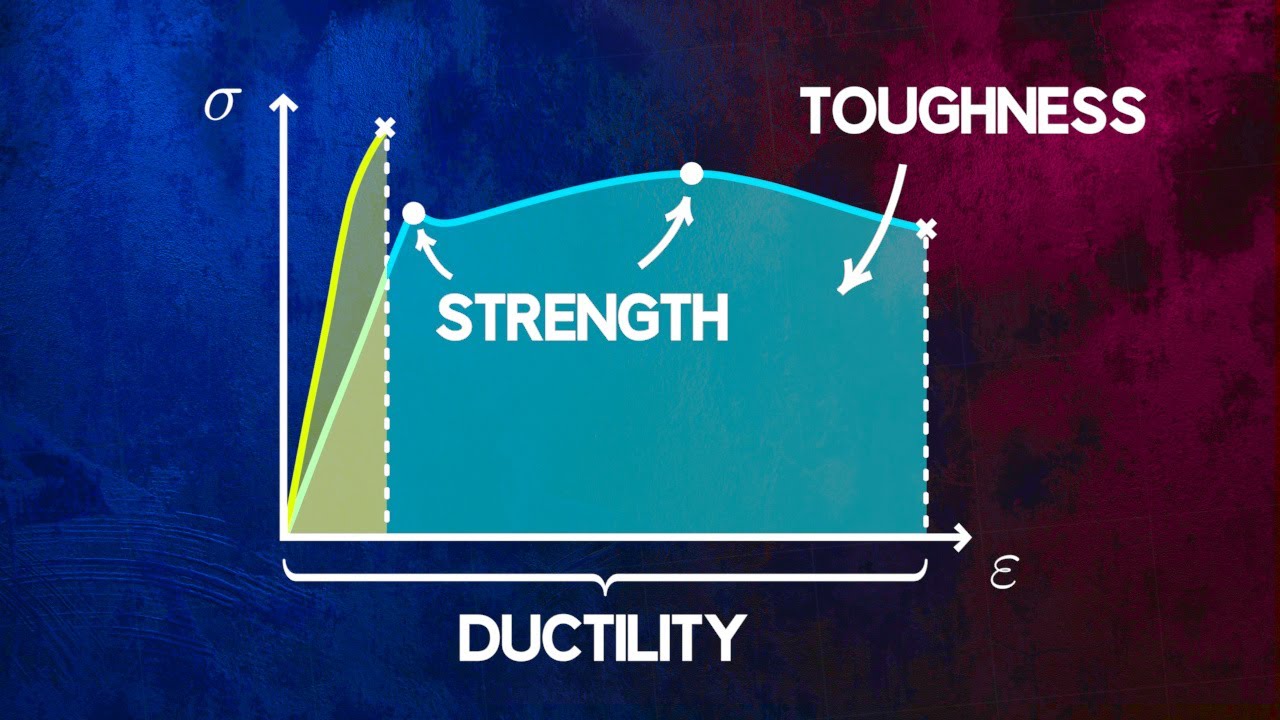

TLDRThe Charpy impact test is designed to measure a material's toughness under impact loading and multiaxial stress. Using a pendulum impact machine, the test evaluates how much energy a specimen absorbs when struck. Two steel specimens, strain-aged and normalized S235, are tested. The strain-aged steel shows brittle behavior, absorbing only 13 joules of energy, while the normalized steel absorbs 182 joules, showing tough behavior with significant plastic deformation. The test also highlights how materials with different crystal structures behave at various temperatures, with body-centered cubic metals becoming brittle at low temperatures.

Takeaways

- ⚙️ The Charpy impact test is designed to measure the toughness of materials under impact loading and multiaxial stress.

- 🔨 A pendulum impact testing machine is used, with a heavy weight that is lifted to the starting position to begin the test.

- 📏 The first step is to check if the machine is properly calibrated by releasing the pendulum without a specimen, ensuring it stops at zero.

- 🔧 The first test is conducted on strain-aged plain carbon steel (S235) with a standardized v-shaped notch specimen.

- ⚡ The pendulum hits the specimen, and the absorbed energy, shown as 13 joules in the first test, is measured as the difference in potential energy.

- ❄️ The first specimen shows brittle behavior with only slight plastic deformation, indicating a low ability to absorb impact energy.

- 🔬 The second test is performed on normalized steel (S235), which absorbs significantly more energy (182 joules) and exhibits tough behavior with heavy plastic deformation.

- 🌡️ The Charpy impact test can be conducted at various temperatures, especially useful for materials with body-centered cubic crystal structures like plain carbon steel.

- 📉 Body-centered cubic steels show an s-shaped curve of impact energy vs. temperature, with a ductile-to-brittle transition.

- 🧊 Face-centered cubic materials, in contrast, retain their ductile behavior even at low temperatures, making them ideal for low-temperature applications.

Q & A

What is the purpose of the Charpy impact test?

-The Charpy impact test is designed to measure the toughness of materials under impact loading and multiaxial stress states.

What type of machine is used in the Charpy impact test?

-A pendulum impact testing machine is used, where a pendulum with a heavy weight is released to strike a test specimen.

How does the tester ensure that the machine is properly adjusted before the test?

-The tester releases the pendulum without a specimen to check that the drag indicator stops at position zero, indicating the correct starting position and friction compensation.

What are the characteristics of the test specimen used in the Charpy test?

-The test specimen is machined to a standardized size and shape with a characteristic V-shaped notch, which is essential for measuring its toughness.

How is the energy absorbed by the specimen calculated in the test?

-The energy absorbed by the specimen is the difference between the potential energy of the pendulum before and after impact, which is read from the position of the drag indicator.

What was the energy absorbed by the strain-aged plain carbon steel specimen in the first test?

-The strain-aged plain carbon steel specimen absorbed only 13 joules of energy, indicating brittle behavior.

What differences were observed in the second test with the normalized steel specimen?

-The normalized steel specimen absorbed 182 joules of energy and showed heavy plastic deformation, indicating much tougher behavior compared to the strain-aged steel.

What does the appearance of the fracture surface indicate about the material’s behavior?

-A flat, glittering fracture surface indicates brittle behavior, while heavy plastic deformation suggests ductile behavior.

How does temperature affect materials with a body-centered cubic (BCC) crystal structure in the Charpy test?

-Materials with a BCC crystal structure show a ductile-to-brittle transition with temperature. At high temperatures, they absorb more energy (tough behavior), while at low temperatures, they absorb less energy (brittle behavior).

Why are face-centered cubic (FCC) materials better suited for low-temperature applications?

-FCC materials do not experience a ductile-to-brittle transition and retain their ductile behavior even at low temperatures, making them suitable for low-temperature applications.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآن5.0 / 5 (0 votes)