Pulp and Paper Making Process ( Proses Pembuatan Pulp dan Kertas )

Summary

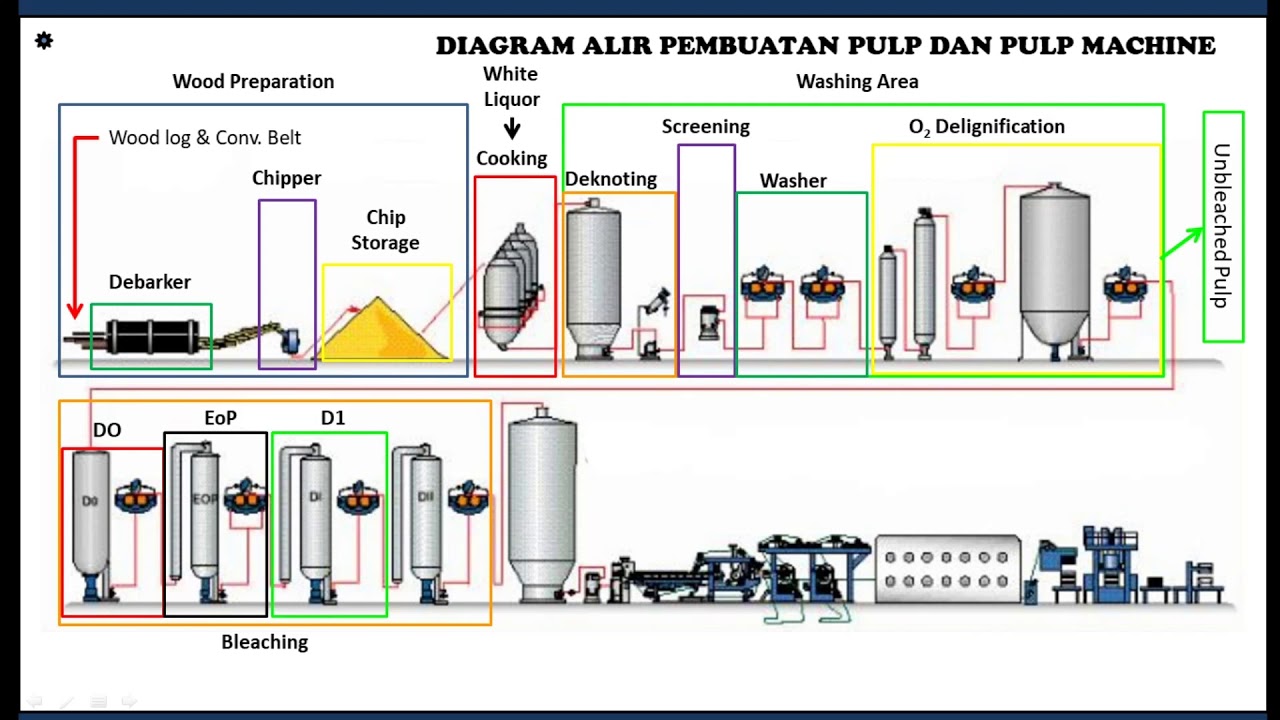

TLDRThis video explains how APRIL Group sustainably produces pulp and paper in Riau, Indonesia. The company generates 2.8 million tons of pulp and 1.5 million tons of paper annually, using acacia and eucalyptus trees from their plantations. The process includes harvesting trees, peeling bark for fuel, chipping the wood, and cooking it to produce pulp. The pulp is whitened, dried, pressed into thin sheets, and finished into rolls. APRIL focuses on water recycling, environmental responsibility, and continuous investment in advanced recycling technology to reduce environmental impact, emphasizing their commitment to sustainability.

Takeaways

- 🌳 APRIL produces 2.8 million tons of pulp and 1.5 million tons of paper annually, with operations in Pangkalan Kerinci, Riau.

- 🌱 The company emphasizes sustainability in paper production, sourcing materials from acacia and eucalyptus trees grown in five Riau provinces.

- 🌍 APRIL plants 200 million tree seedlings each year to ensure a continuous supply of raw materials and environmental preservation.

- 🧪 APRIL operates four integrated nurseries and an R&D department to develop the best tree seedlings for paper production.

- 🪵 The papermaking process begins with trees being transported from plantations to mills, where the bark is removed since it’s not usable for paper.

- ⚡ The removed bark is used as fuel to generate electricity for both the mill and nearby communities.

- 📝 Wood chips are cooked to dissolve lignin, producing pulp which is then bleached and dried into sheets for easy transportation.

- 🔄 APRIL recycles water and has invested in advanced processing facilities to minimize environmental impact.

- 📜 The second key process involves pulp being pumped into machines at high speeds, forming thin sheets that are pressed and dried at 100°C.

- 📦 The final step involves finishing, cutting, and packaging the paper into rolls or sheets according to customer needs.

Q & A

What materials are primarily used by APRIL for paper production?

-APRIL primarily uses acacia and eucalyptus trees as raw materials for paper production, which are grown in plantations across five districts in Riau Province, Indonesia.

How does APRIL ensure sustainability in its paper production process?

-APRIL ensures sustainability by following policies aimed at preserving nature. The company plants 200 million tree seedlings annually and integrates advanced recycling and water treatment facilities to minimize environmental impact.

What are the three key stages in APRIL's paper-making process?

-The three key stages are: 1) transporting and debarking the harvested trees, 2) cooking the wood chips to dissolve lignin and create pulp, and 3) forming and drying the pulp into paper sheets.

How does APRIL utilize by-products from the paper-making process?

-APRIL uses by-products like tree bark and other waste materials as fuel to generate electricity for both the factory and nearby villages.

What is the significance of the 'ship formation' process in paper production?

-'Ship formation' is the process where the pulp mixture is spread into thin sheets on a moving screen at high speeds (80-90 km/h), helping to form the initial structure of the paper.

How is the moisture content of the paper reduced during production?

-The moisture content is reduced during the pressing stage, where 50% of the water is squeezed out of the paper, followed by drying at around 100°C using metal cylinders.

What measures does APRIL take to reduce water usage in the production process?

-APRIL recycles water used in the production process by filtering and reusing it for washing the wood, thereby reducing the overall water consumption.

What is the role of the finishing process in paper production?

-In the finishing process, the surface of the paper is coated with compounds to improve its quality, then dried again and rolled into large sheets for cutting and packaging according to customer needs.

How much pulp and paper does APRIL produce annually?

-APRIL produces 2.8 million tons of pulp and 1.5 million tons of paper annually.

Where does APRIL operate, and what is its commitment regarding sustainability?

-APRIL operates in Pangkalan Kerinci, Pelalawan Regency, Riau Province, Indonesia, and is committed to sustainability, focusing on eco-friendly practices and the responsible use of resources.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

How Paper Is Made

SERING PAKE, TAPI GAK TAU PROSESNYA? TERNYATA BEGINI TAHAP PEMBUATAN KERTAS DARI AWAL HINGGA AKHIR

Papermaking (1) Forming

How is PAPER Made from WOOD? Amazing Paper Production Factory!

Kimia Industri - Pembuatan Pulp dan Kertas (Diagram Alir proses) (Bag. 2 - Akhir)

Terbongkar! Perusahaan Indonesia dan Ilusi Hijau yang Menipu Eropa | Buka Mata

5.0 / 5 (0 votes)