Ship's Fresh Water Generator (Distillation Plant) | Starting and Stopping Procedures | Chief MAKOi

Summary

TLDRThis video offers an in-depth look at the operation of a distillation plant aboard cargo ships, crucial for converting seawater into fresh water. It outlines the start-up and shutdown procedures, emphasizing the importance of the main engine's jacket water outlet as a heat source. The video explains the role of the ejector pump in creating a vacuum for boiling seawater at lower temperatures, the heat exchange process in the evaporator, and the collection of distilled water in the condenser. It also covers the critical steps of monitoring salinity with a salinometer and the disposal of non-evaporated seawater, ensuring the plant's efficient and safe operation.

Takeaways

- 🚢 Ocean-going ships use freshwater generators or desalination plants to convert seawater into fresh water due to the limited usability of seawater.

- 💧 The most common method for cargo ships is distillation, which requires the main engine to be running at navigation full speed.

- 🔥 The heating medium for distillation plants typically comes from the main engine's jacket water outlet, which is around 85-90 degrees Celsius.

- 🌊 It's important for ships to be in deep water and far from land to ensure the seawater used is clean and free of pollutants.

- 📦 The distillation process involves drawing seawater, creating a vacuum with an ejector pump, and heating the water to evaporate it in the evaporator.

- 🌡️ The boiling point of seawater is lowered inside the evaporator due to the vacuum created, allowing it to evaporate at temperatures below 100 degrees Celsius.

- 💧 The steam from the evaporator is condensed back into fresh water in the condenser, which is then collected and stored.

- 🔍 A salinometer is used to measure the salinity of the distilled water, ensuring it meets the required standards before being stored.

- 🚫 If the salinity is too high, an alarm is triggered, and the water is returned to the system to prevent contamination of the fresh water storage.

- 🛑 The shutdown process of the distillation plant is the reverse of the startup, ensuring the system cools down to prevent salt and scale buildup.

Q & A

Why do ocean-going ships need a freshwater generator?

-Ocean-going ships need a freshwater generator because seawater, despite being abundant, has high salinity which makes it unsuitable for most shipboard operations and human requirements.

What are the two main methods used to convert seawater into fresh water on ships?

-The two main methods used to convert seawater into fresh water on ships are distillation and reverse osmosis.

Which type of desalination plant is most commonly used on cargo ships?

-The most commonly used type of desalination plant on cargo ships is the distillation plant.

What is the source of heating for the distillation plant on most ships?

-The source of heating for the distillation plant on most ships is the jacket water outlet of the main engine, which typically has a temperature range between 85 to 90 degrees Celsius.

Why should the ship be far from land and in deep water when operating the distillation plant?

-The ship should be far from land and in deep water to ensure that the seawater drawn into the distillation plant is clean and free of pollutants.

What is the role of the ejector pump in the distillation process?

-The ejector pump creates a venturi effect, generating suction that helps maintain a vacuum inside the shell, which is necessary for the evaporation process to occur at lower temperatures than the boiling point of seawater.

How does the feed water line contribute to the efficiency of the distillation plant?

-The feed water line draws seawater from the upper part of the condenser, preheating the feed water and improving the efficiency of the distillation process.

What is the purpose of the salinometer in the distillation plant?

-The salinometer measures the salinity of the distilled water. If the salinity is higher than the set limit, an alarm is triggered, and the water is returned to the shell to prevent contaminated water from entering the freshwater storage tanks.

What happens to the salt that is not evaporated during the distillation process?

-The salt remains dissolved in the seawater that hasn't evaporated and is suctioned by the inductor and pumped out into the sea as part of the continuous flow system.

What is the procedure to stop the distillation plant before the ship arrives in port?

-The procedure to stop the distillation plant before the ship arrives in port involves switching off the dosing pump and salinometer, stopping the flow of heating into the evaporator, allowing the evaporator to cool down, stopping the ejector pump, closing all relevant valves, and opening the vacuum breaker.

Outlines

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنMindmap

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنKeywords

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنHighlights

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنTranscripts

هذا القسم متوفر فقط للمشتركين. يرجى الترقية للوصول إلى هذه الميزة.

قم بالترقية الآنتصفح المزيد من مقاطع الفيديو ذات الصلة

How Ships Convert Sea Water to Fresh Water | Chief MAKOi Study Call Ep 04

Fresh Water Generator on Ships | 3D Animated Explanation | HIMT

How A Container Ship Secures Containers - Design, Safety, Container Locating

How Seawater Desalination Works

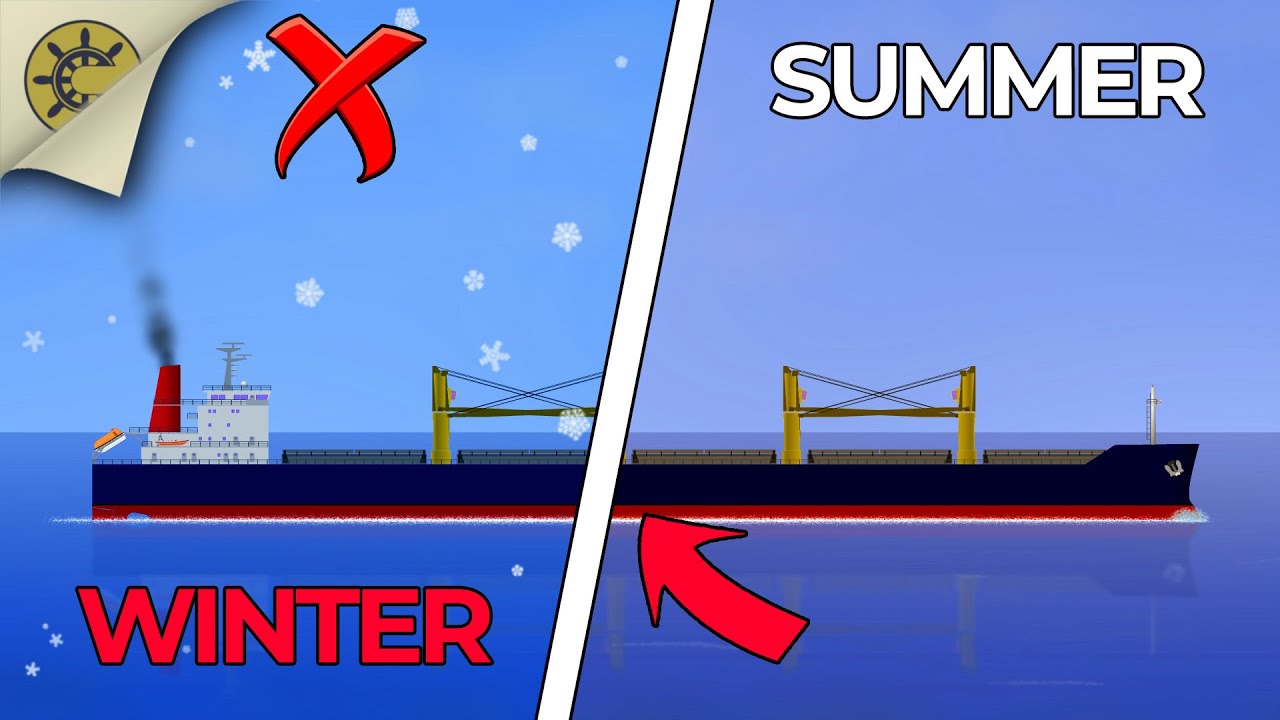

Why Do Ships Carry Less In Winter?

HOW IT WORKS: The International Space Station

5.0 / 5 (0 votes)