How Mechanical Engineers Design Products

Summary

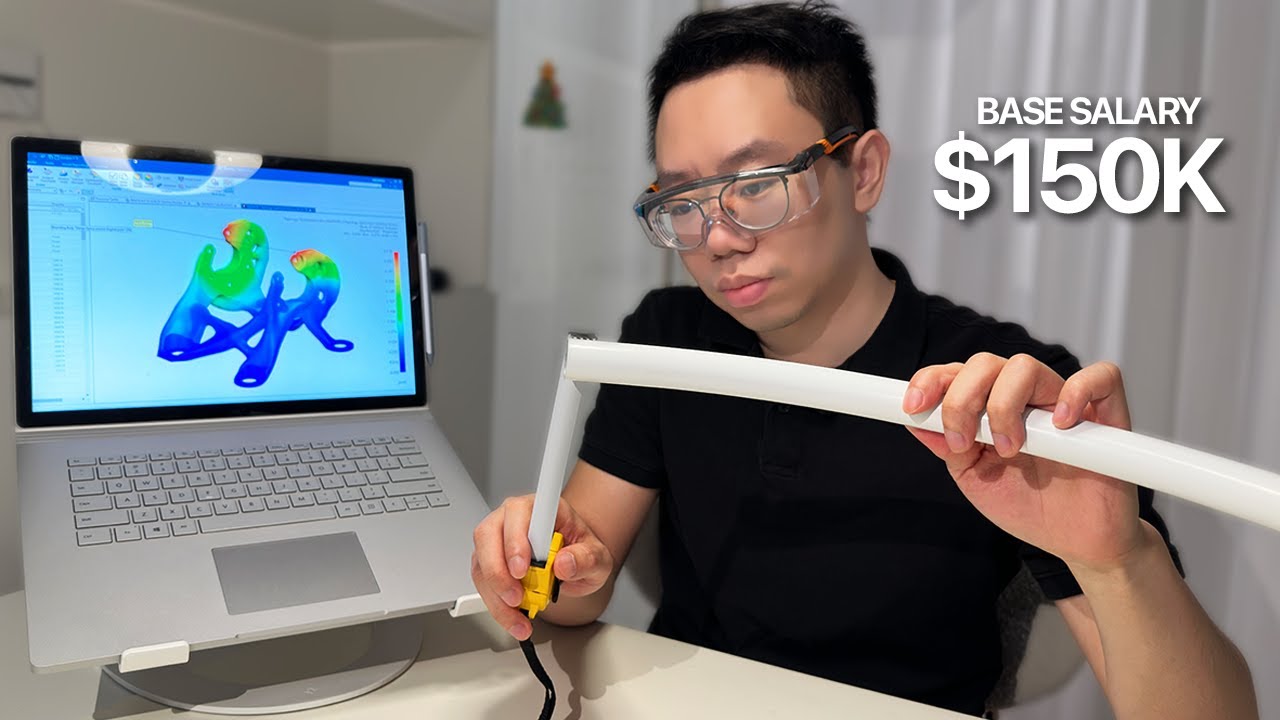

TLDRThis video script offers an in-depth look into the life cycle of product development from concept to market, through the eyes of a mechanical engineer. It covers the initial idea phase, the influence of high-level stakeholders, and the crucial role of engineers in material selection and design. The script also introduces Jigado.io, a platform simplifying the custom parts manufacturing process by connecting creators with vetted suppliers. The detailed design process, DFMA principles, and the importance of communication and project management in the product development process are highlighted, emphasizing the impact of engineering on a company's success.

Takeaways

- 🔍 The product development process begins with an idea and involves high-level discussions among key stakeholders before engineers get involved.

- 🛠️ Mechanical engineers typically enter the process later and have a significant role in the detailed design, ensuring manufacturability and functionality.

- 📱 The material choice for products like the iPhone is a collaborative decision involving engineering, marketing, and supply chain considerations.

- 🎨 Industrial design teams work with marketing to determine product dimensions and create a digital model that guides the mechanical engineering team's work.

- 🤖 The product development process (PD process) includes stages like conceptualization, design, validation, product introduction, and manufacturing ramp-up.

- 📐 High-level design involves determining overall dimensions and layouts of key parts, while detailed design focuses on specific features and manufacturing methods.

- 💼 The COO's input is crucial for material availability, costs, supplier reliability, and potential risks from a supply chain perspective.

- 🔨 Mechanical engineers must consider design for manufacturing and assembly (DFMA) principles to avoid costly mistakes and delays.

- 🔄 Regular communication with vendors and other engineering teams is essential to stay updated on design changes and potential issues.

- 🛠️ Involving the sourcing or purchasing department early in the design process can prevent redesigns due to manufacturability issues.

- 📈 Mechanical engineers use various tools and analyses, such as finite element analysis and computational fluid dynamics simulations, throughout the PD process to improve designs.

Q & A

What is the initial stage of the product development process described in the script?

-The initial stage of the product development process described in the script is the conceptualization phase, where high-level discussions take place within a company among key stakeholders to decide on the new products the company will pursue.

Who typically has a say in what new products a company will pursue?

-Senior leaders such as the CEO, COO, VPs, and the senior VP of Hardware Engineering typically have a say in what new products a company will pursue.

What role does the VP of marketing play in the product offering?

-The VP of marketing has a voice in the overall product offering for the current and subsequent years, including decisions on the product's dimensions, colors, surface finishes, storage, key features, and materials.

Why might a company choose different materials for different models of the same product, like the iPhone 15 and iPhone 15 Pro?

-A company might choose different materials for different models to differentiate the products based on competition, consumer preferences, and brand positioning. For example, using titanium for the iPhone 15 Pro can reinforce its premium status, while aluminum for the iPhone 15 positions it as a more accessible option.

What is the role of the industrial design team in the product development process?

-The industrial design team works with marketing to determine the ideal overall product dimensions and creates a digital surface model representing the exterior shape of the product based on the requirements given by marketing.

What is the PD process and what are its general stages?

-The PD process, or product development process, is the series of stages a product goes through from conceptualization to market introduction. The general stages include conceptualization, design, validation and testing, product introduction, and manufacturing ramp.

What is the purpose of the high-level design stage in the design process?

-The purpose of the high-level design stage is to determine the overall dimensions, geometries, positions, and layout of key parts using relatively simple 3D models, without detailed analysis at this stage.

Why is CAD software important for mechanical engineers?

-CAD software is important for mechanical engineers as it allows them to visualize the overall design, including interferences and collisions between parts, change and adjust dimensions and geometries on the fly, and output various file formats for different use cases.

What is the significance of involving the sourcing or purchasing department and vendors early in the design process?

-Involving the sourcing or purchasing department and vendors early in the design process helps to avoid costly mistakes and redesigns later on, ensures manufacturability, and allows for feedback on design for manufacturability (DFM) principles.

What is jiga.doio and how does it help in the manufacturing process?

-Jiga.doio is a custom parts manufacturing platform that connects customers with a network of vetted suppliers, allowing direct communication of requirements. It simplifies the process of sourcing parts, provides quotes quickly, and ensures parts are made according to specifications, faster and more affordably.

Why is it important for mechanical engineers to stay organized, especially when working on products with many parts?

-Staying organized is crucial for mechanical engineers to keep track of part and drawing numbers, design changes, and revisions. This organization prevents confusion and errors, ensuring that the product development process runs smoothly and efficiently.

What are some of the common pitfalls that inexperienced mechanical engineers might face during the design process?

-Inexperienced mechanical engineers might focus solely on the design aspect and neglect manufacturing and assembly considerations. They might also fail to communicate effectively with vendors and other engineering teams, leading to delays and design issues.

What is the role of project managers in a mechanical engineering project?

-Project managers lead the charge in mechanical engineering projects, overseeing the schedule, key milestones, and deadlines. They are responsible for coordinating the efforts of various individuals and teams, ensuring that the project stays on track and meets its objectives.

How can mechanical engineers ensure their designs are optimized for manufacturing?

-Mechanical engineers can ensure their designs are optimized for manufacturing by applying design for manufacturing and assembly (DFMA) principles, asking the right questions about manufacturability, and maintaining open communication with vendors and other engineering teams.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

What do I do as a Mechanical Engineer?

Car Tech 101: What you need to know about car batteries (On Cars)

How to build a LEGAL BASEMENT from START to FINISH 🔨👷

Music Royalties 101

Female Reproductive Cycles Made Easy!

PART-1: Technical Evaluation of Centrifugal Pump Mechanical Datasheet with respect to API 610

5.0 / 5 (0 votes)