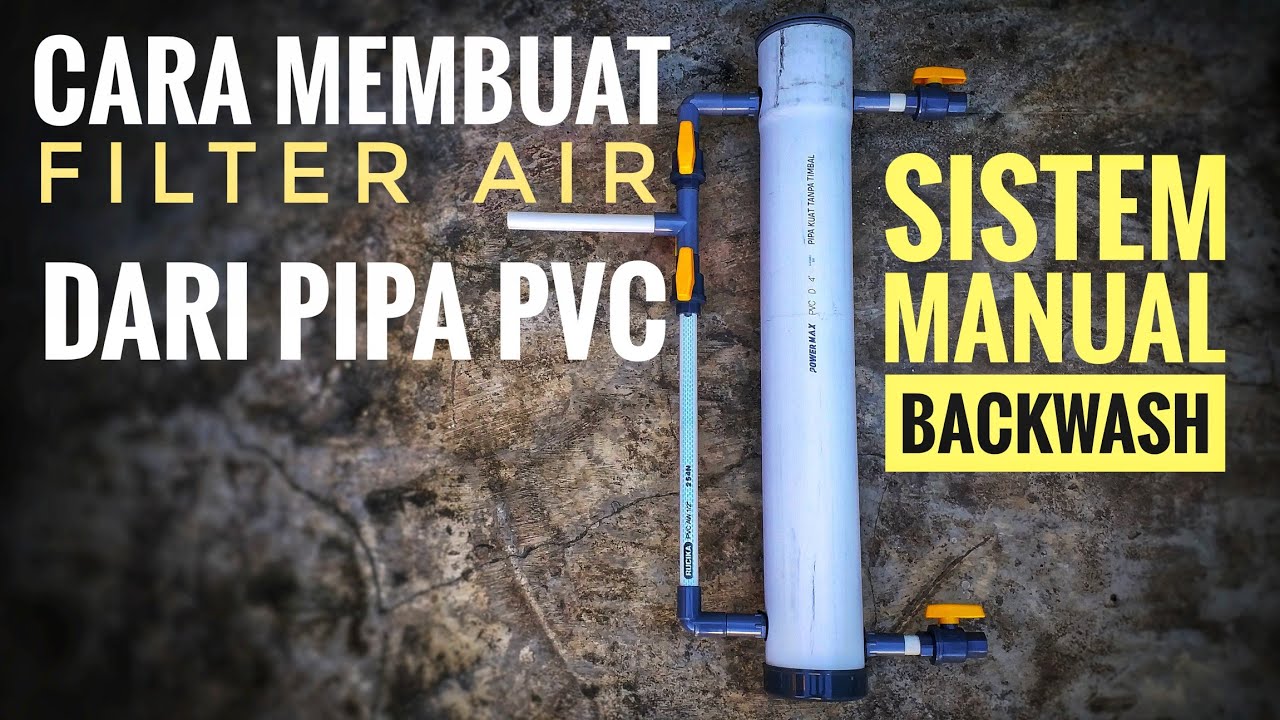

The Manufacturing Process Unveiled | Creating Strong and Reliable PVC Pipes in the Factory

Summary

TLDRThis video showcases the entire process of PVC pipe manufacturing. It starts with the raw materials being loaded into a mixture machine and filtered. The mixture is then processed in a machine that shapes the pipes while maintaining their size. A printing machine applies labels, and the pipes are cut to the desired length. The pipes undergo heating to seal one side before being tested for strength by a car rolling over them, proving their durability. The video highlights the efficiency and precision involved in creating high-quality PVC pipes.

Takeaways

- 😀 The process of making PVC pipes starts with loading raw materials into a mixture machine.

- 😀 The raw mixture is then filtered to remove impurities.

- 😀 The cleaned mixture is loaded into a machine to form the pipes.

- 😀 The pipes undergo a cooling process after being shaped.

- 😀 A machine ensures that the pipes maintain their size and shape during production.

- 😀 Printing is done on the pipes using a specialized printing machine.

- 😀 The pipes are then cut into the desired lengths using a cutting machine.

- 😀 One side of the pipe is heated to create a specific feature in the pipe.

- 😀 After production, the pipes undergo a quality test to ensure they meet standards.

- 😀 In a strength test, a car is driven over the pipe, and it remains intact, demonstrating its durability.

Q & A

What is the first step in the process of making PVC pipes?

-The first step is loading the raw materials into the mixture machine.

What happens after the raw materials are loaded into the mixture machine?

-The raw materials are filtered to clean the mixture before proceeding further.

What happens after the mixture is cleaned?

-The cleaned mixture is loaded into a machine to begin the shaping process of the pipes.

How are the pipes cooled during the manufacturing process?

-The pipes are cooled through a cooling machine to ensure they solidify and retain their shape.

How is the size and shape of the pipe maintained?

-The size and shape of the pipe are controlled by a machine that ensures consistency.

How is the printing done on the PVC pipes?

-A printing machine is used to apply printing on the pipe.

What happens to the pipes after printing?

-After printing, the pipes are cut using a cutting machine to the required length.

What is done to one side of the pipe during the process?

-One side of the pipe is heated to facilitate further processes, likely for bending or joining.

What test is performed to check the strength of the PVC pipe?

-A car is passed over the pipe to check its strength, and the pipe remains intact.

What is the final outcome of the PVC pipe manufacturing process?

-The final product is a fully manufactured and tested PVC pipe, ready for use.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级5.0 / 5 (0 votes)