30 - Galvanic corrosion

Summary

TLDRThis video discusses the risks of galvanic corrosion in the oil industry, particularly when different metals come into contact in adverse weather conditions. It explains how materials with different electrochemical potentials can lead to one metal corroding faster than the other, leading to equipment failure. The video provides practical advice on how to prevent galvanic corrosion when selecting materials and securing equipment, including using isolating washers, appropriate bolts, and sacrificial anodes. The importance of inspections and following safety guidelines is also emphasized to prevent accidents and equipment damage.

Takeaways

- 😀 Galvanic corrosion occurs when two different metals or alloys with different electrochemical potentials come into contact with each other, leading to corrosion.

- 😀 In the oil industry, equipment exposed to harsh weather conditions may experience galvanic corrosion if incorrect methods of securing are used.

- 😀 Galvanic corrosion happens when the less noble metal (anode) corrodes faster than the more noble metal (cathode) when they are in contact under water or damp conditions.

- 😀 If a galvanized steel screw is used to fasten stainless steel equipment, the screw will corrode quickly because the stainless steel is more noble.

- 😀 Galvanic corrosion can also occur between parts of the same metal if they are in different environments with varying pH values.

- 😀 To prevent galvanic corrosion, it is essential to choose bolts and fasteners made of materials with similar electrochemical nobilities.

- 😀 When securing aluminum parts, use a nonmetal washer to isolate the aluminum from other metals and prevent corrosion around the bolts.

- 😀 A weakness in the isolating washer can lead to bolts losing their tension, causing potential safety hazards such as falling equipment.

- 😀 Painting surfaces can help prevent galvanic corrosion, but always paint the more noble metal (cathode) to avoid corrosion in the event of cracks in the paint.

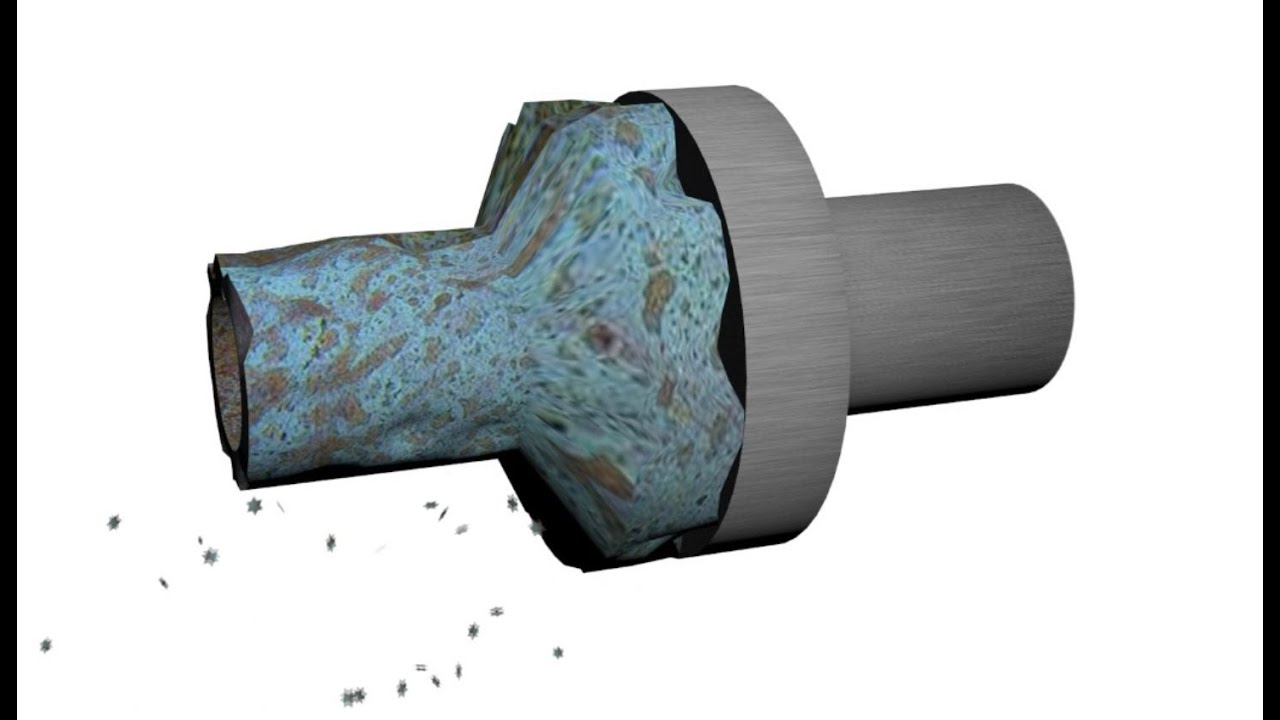

- 😀 Isolation spools made of non-conductive materials like GRP or rubber should be used to prevent galvanic corrosion in seawater systems, but they are not recommended for hydrocarbon piping.

- 😀 Regular inspections and adherence to specifications can help identify and mitigate the risk of galvanic corrosion, preventing accidents or near-misses.

Q & A

What is galvanic corrosion and how does it occur?

-Galvanic corrosion occurs when two different metals or alloys with different electrochemical potentials come into contact in a damp or underwater environment. The less noble metal acts as the anode, and the more noble metal acts as the cathode. The anode corrodes as a result of this contact.

What happened on the oil platform that resulted in equipment failure?

-On a relatively new platform, sound boards weighing five kilograms fell down a few years after installation. This was due to galvanic corrosion, as the boards were fastened directly to the steel structure using aluminum hot rivets, which led to the corrosion of the materials.

How does galvanic corrosion affect materials like stainless steel and galvanized steel?

-When a galvanized steel screw is used to secure stainless steel equipment, the screw becomes the anode because galvanized steel is less noble than stainless steel. The electrochemical potential difference between the metals causes the screw to corrode more quickly.

Can galvanic corrosion occur between parts of the same metal?

-Yes, galvanic corrosion can occur between parts of the same metal if the parts are in different environments with varying pH values. The parts must be in electrical contact for galvanic corrosion to take place.

How can galvanic corrosion be prevented during equipment installation?

-To prevent galvanic corrosion, ensure that materials with similar or almost identical nobilities are used together. If different materials must be used, isolation techniques such as nonmetal washers or surface coatings can be applied to prevent direct contact.

What is the role of isolation washers in preventing galvanic corrosion?

-Isolation washers made of nonmetal materials are used to prevent direct contact between metals of different electrochemical potentials, reducing the risk of galvanic corrosion. They help isolate the metals, but their weakness is that they may cause bolts or screws to lose their pre-tension.

What are the potential consequences of not using isolation washers or appropriate materials?

-Without isolation washers or appropriate materials, galvanic corrosion can occur, weakening the connection. This can result in equipment failure, such as signs working loose and falling down due to the corrosion of bolts, leading to safety hazards.

What is the best practice for using bolts in corrosive environments?

-In corrosive environments, choose bolts that are appropriate for the load and surrounding conditions. Use materials with similar nobilities, and isolate different metals with nonmetal washers or coatings to avoid galvanic corrosion.

How does painting surfaces help prevent galvanic corrosion?

-Painting the surfaces of metals can prevent galvanic corrosion by isolating the materials. However, it is essential to paint the more noble material (the cathode). If the anode is painted and a crack occurs in the paint, galvanic current can flow to that point, causing significant corrosion.

What measures can be taken to protect piping systems from galvanic corrosion?

-To protect piping systems, ensure that bolts and packing rings are made of the correct material, especially when two different types of metal are involved. Isolation spools made of non-conductive materials like GRP or epoxy-coated surfaces can also be used to prevent galvanic corrosion in sea water systems.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Galvanic Corrosion | Forms of Corrosion

Video Pembelajaran Kimia Materi Korosi pada Logam Dilengkapi dengan Animasi

What is Corrosion? Corrosion of Iron — Corrosion of Metal — How Corrosion Occurs in Metals 2021

Percobaan Korosi

Ag Forecast for Australia with Eric Snodgrass (in-depth) | Aug 7, 2024

Ship Hull Protection System

5.0 / 5 (0 votes)