4.1 Production of goods and services IGCSE Business Part 1

Summary

TLDRThis video covers the essential concepts of production and productivity in business, including the processes and methods involved in creating goods and services. It explains the role of lean production techniques like Kaizen, Just-in-Time, and Cell Production in reducing waste and improving efficiency. Key topics include inventory management, the benefits of increasing productivity, and the importance of using technology to optimize operations. The video provides practical insights for businesses seeking to boost competitiveness and profitability by cutting costs, enhancing quality, and streamlining production processes.

Takeaways

- 😀 Production is the process of adding value to goods and services using land, labor, capital, and enterprise to meet customer needs.

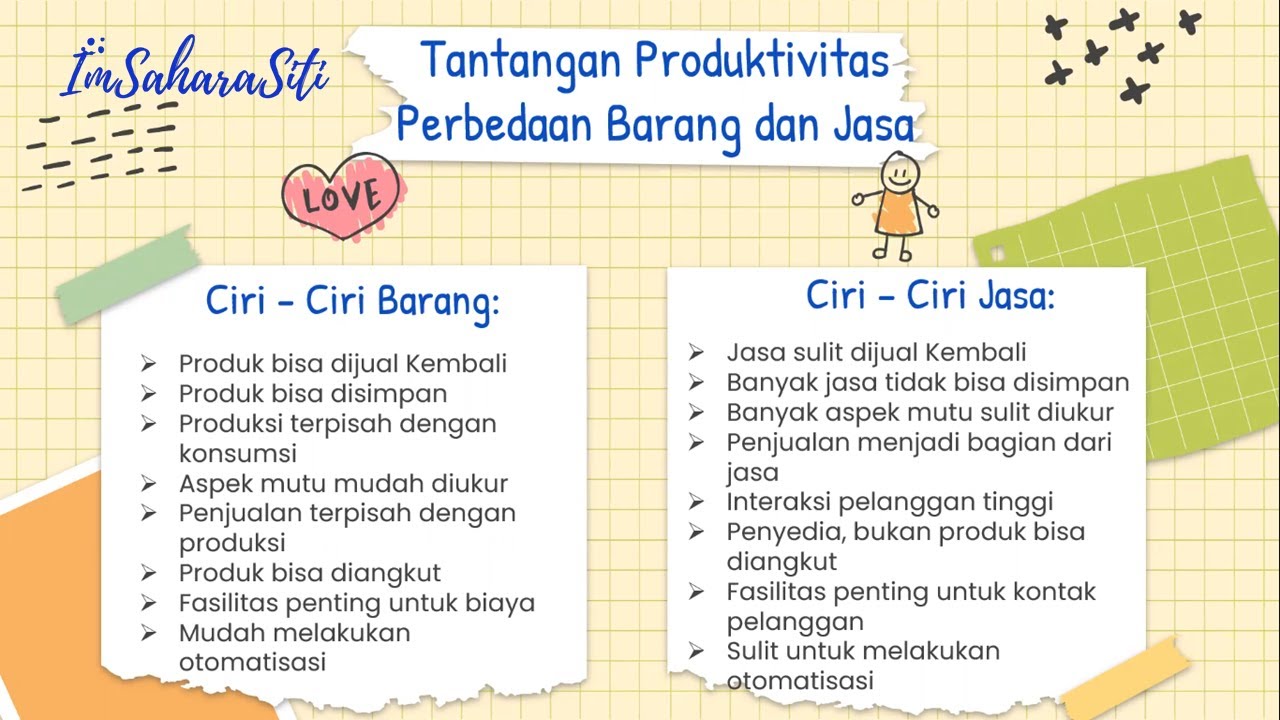

- 😀 Productivity measures business efficiency, aiming to produce more output with the same or fewer inputs.

- 😀 Businesses can improve productivity by optimizing factory layouts, training workers, and introducing automation (e.g., robots or machines).

- 😀 High productivity leads to increased profits, reduced labor costs, improved competitiveness, and better overall efficiency.

- 😀 Inventory management is crucial: businesses hold stock to meet demand variations, take advantage of price discounts, and hedge against price increases.

- 😀 Holding excessive inventory can lead to increased storage costs, product waste, and missed opportunities for other investments (opportunity cost).

- 😀 Buffer stock ensures that businesses have extra inventory to manage demand fluctuations or delays from suppliers.

- 😀 Lean production focuses on minimizing waste and improving efficiency through continuous improvement, employee involvement, and quality management.

- 😀 Kaizen (continuous improvement) and just-in-time production are key lean production techniques that eliminate waste and reduce unnecessary costs.

- 😀 Just-in-time production reduces the need to hold raw materials in stock by synchronizing delivery with production, ensuring efficient use of space and resources.

- 😀 Cell production divides the production process into separate teams responsible for specific tasks, improving motivation, quality, and customer responsiveness.

Q & A

What is the meaning of production?

-Production is the process of adding value to a product using the four factors of production: land, labor, capital, and enterprise to satisfy customer needs. It also involves converting tangible and intangible inputs into goods or services.

How is productivity different from production?

-Productivity measures a business's efficiency, showing how well it uses its resources. It can be increased by producing more output with fewer inputs or using the same input to generate more output.

What are some ways businesses can improve productivity?

-Businesses can improve productivity by optimizing the layout of factories, training employees, using automation, reviewing employee performance, and ensuring clear communication and goal-setting.

What are the advantages of improving productivity?

-Improving productivity leads to lower costs per unit, reduced labor costs, increased profits, improved competitiveness, and more engaged and productive workers.

Why do businesses hold inventories?

-Businesses hold inventories to meet variations in customer demand, manage unexpected spikes in demand, smooth out seasonal demand, take advantage of discounts, and hedge against price increases.

What are the risks of holding too much inventory?

-Holding too much inventory can result in high storage costs, wasted space, and potential damage or expiration of products. It also increases opportunity costs and handling costs.

What happens if a business does not hold enough inventory?

-Not holding enough inventory can lead to unsatisfied customers, lost sales, decreased profits, and missed opportunities, as competitors might gain customers by having the needed stock.

What is buffer stock and why is it important?

-Buffer stock is an extra quantity of a product held to manage fluctuations in customer demand or supply delays. It ensures a business can continue operations smoothly even during unexpected disruptions.

What is lean production and where did it originate?

-Lean production is a method used to minimize waste while maximizing efficiency. It originated in Japan and focuses on cutting out non-value-adding activities, ensuring quality, and improving productivity.

What are the benefits of lean production?

-Lean production reduces storage costs, minimizes defects, speeds up production, improves quality, increases efficiency, and optimizes space. It also helps in managing resources effectively.

What are some common techniques used in lean production?

-Common techniques in lean production include Kaizen (continuous improvement), Just-in-Time production (producing items as needed), and Cell production (team-based approach for efficiency and quality).

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Menganalisis Biaya Produksi Prototype Produk Barang/Jasa | Produk Kreatif dan Kewirausahaan

PENGETAHUAN DASAR PENGADAAN BARANG/JASA PEMERINTAH

Pengantar Bisnis Sesi 11 Produksi dan Manajemen Operasi

Pengertian Pengadaan Barang/Jasa Pemerintah || Perpres 12 tahun 2021

Resources and their Scarcity

Video Pembelajaran Pengantar Manajemen _ Manajemen Operasional

5.0 / 5 (0 votes)