Kimia Industri - Diagram Alir Proses Pembuatan Gula tebu

Summary

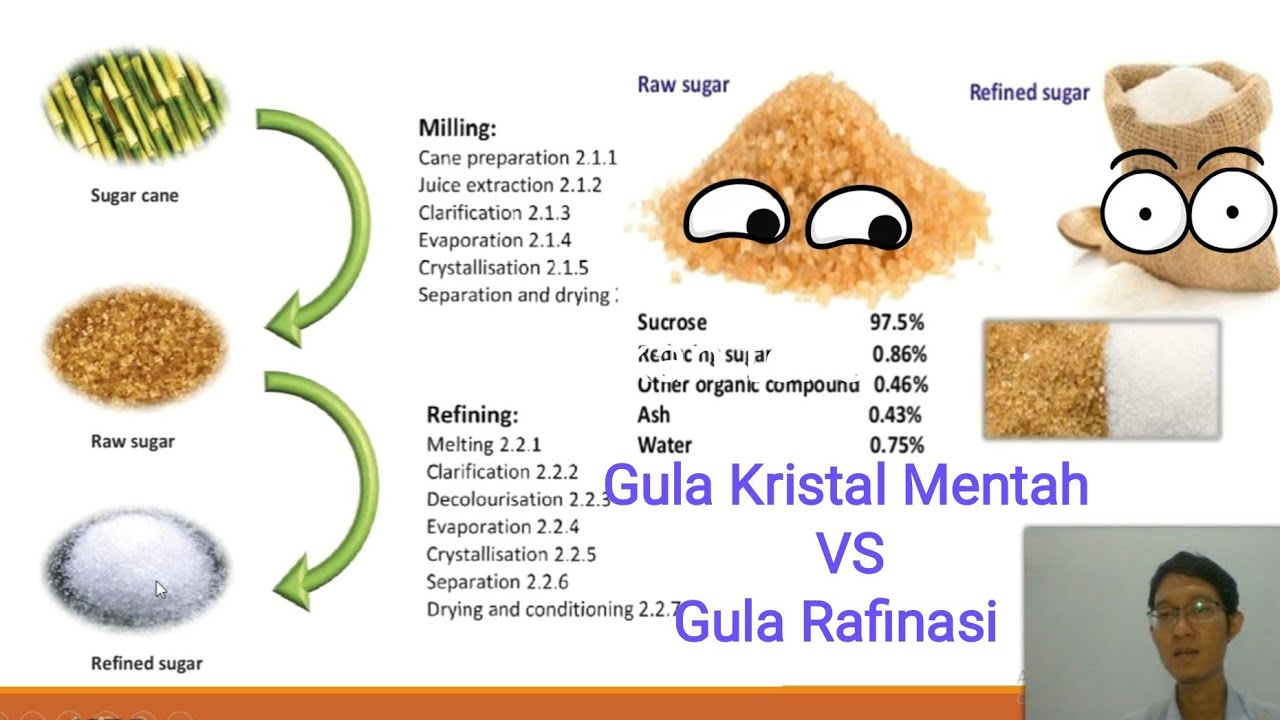

TLDRThis video provides a detailed walkthrough of the sugarcane-to-sugar production process, from the arrival of sugarcane at the plant to the final packaging of sugar. Key steps include the transportation and cutting of sugarcane, juice extraction using a multi-stage milling process, purification through defecation and sulfitation, concentration via multiple-effect evaporation, and crystallization of the syrup into sugar. The video also covers the final stages of drying, screening, and packaging the sugar for market distribution, highlighting the machinery and chemical treatments used to ensure high-quality sugar production.

Takeaways

- 😀 The sugar production process starts with the transportation of sugarcane to the processing facility.

- 😀 The sugarcane is first cut into smaller pieces and then sliced further to enhance juice extraction efficiency.

- 😀 The juice extraction process involves a series of rollers where water (imbibisi) is used to dissolve sucrose from the cane.

- 😀 After extraction, the raw juice (Nira) undergoes a series of purification steps, including heating and lime addition (defecation) to remove impurities.

- 😀 Nira is treated with sulfur dioxide (SO2) to neutralize excess lime and improve the clarity and color of the juice.

- 😀 The clarified juice is evaporated using a multi-effect evaporator system to concentrate the sugar solution.

- 😀 Sulfitation is repeated during evaporation to control color and ensure a clearer final product.

- 😀 The concentrated syrup is then crystallized to form sucrose crystals (sugar), which are separated from the remaining liquid (molasses) through centrifugal force.

- 😀 The crystallized sugar undergoes drying and screening processes to remove excess moisture and separate fine and coarse sugar.

- 😀 The final product is stored in bins and prepared for packaging and distribution to consumers.

- 😀 The entire process is highly efficient, with various stages designed to maximize sugar extraction and minimize waste.

Q & A

What is the first step in the sugar production process from sugarcane?

-The first step is transporting harvested sugarcane to the processing plant. The sugarcane is laid out on a Ken table to be fed into the conveyor system for further processing.

What role does the Ken Cutter play in the sugar production process?

-The Ken Cutter cuts the sugarcane into smaller pieces to facilitate easier processing in the subsequent stages of crushing and juice extraction.

How does MBC water improve the efficiency of sugar extraction?

-MBC water, which is sprayed onto the sugarcane during crushing, helps dissolve sucrose from the sugarcane, improving the efficiency of the extraction process.

What is Nira, and what happens to it after extraction?

-Nira is the raw juice extracted from the sugarcane. After extraction, it undergoes a purification process to remove impurities before being concentrated in later stages.

How does the defecation process improve the quality of Nira?

-During defecation, lime milk (susu kapur) is added to the Nira to neutralize acids and form precipitates, which helps clarify the juice and increase its pH, reducing the risk of damage due to acidic conditions.

What is the purpose of the sulfitation process in sugar production?

-Sulfitation is used to neutralize any excess lime (CaOH2) and prevent the Nira from turning brown. This step helps produce clearer juice, ensuring that the final sugar product is white in color.

What is the function of the evaporators in the sugar production process?

-Evaporators concentrate the Nira by removing water. The Nira is heated in multiple stages using a multiple-effect evaporator, which increases the sucrose concentration to prepare it for crystallization.

How does the crystallization process work in sugar production?

-In crystallization, concentrated syrup is cooled, and sugar crystals begin to form. The process is carried out in pan evaporators, where fine crystal seeds are added to facilitate crystal growth.

What happens to the molasses produced during crystallization?

-Molasses, the liquid remaining after sugar crystals are separated, is removed and can be used for other purposes, such as animal feed or further processing.

Why is drying and screening an important final step in sugar production?

-Drying and screening remove moisture from the sugar and ensure that it reaches the desired consistency. The sugar is then sifted to separate fine and coarse particles before being packaged and stored for distribution.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

How Modern Factory Producing Crystal Sugar Efficiently?

Sering Dikonsumsi, Tapi Ga Tau Prosessnya? Begini Cara Kerja Mesin Gula Pasir Dari Awal Hingga Akhir

Ekstraksi Tebu menjadi Nira - Diagram Alir Proses Industri Gula (part 1/4)

Pabrik Pembuatan Gula Pasir | SI UNYIL (17/03/20) PART 1

PENGOLAHAN LIMBAH CAIR AGROINDUSTRI GULA - METODE FISIKA BIOLOGI

THIS IS THE MODERN PROCESS OF SUGAR FARMING IN AUSTRALIA | THE SECRET BEHIND EXPORTED GRANULATED ...

5.0 / 5 (0 votes)