Dial Gauge (Dial Indicator): Komponen, Fungsi dan Cara Menggunakan

Summary

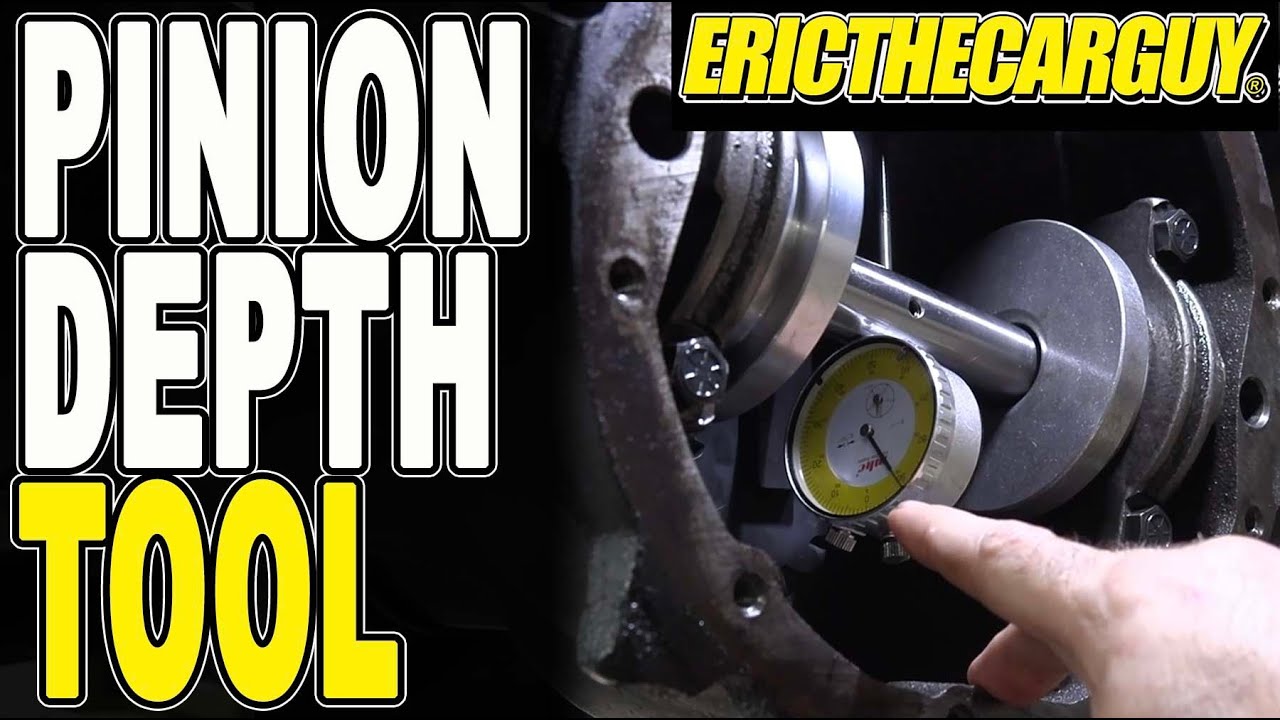

TLDRThis instructional video on automotive technology explains how to effectively use a dial indicator, a tool essential for measuring parameters like shaft run-out and alignment. The video details the components of the dial indicator, including the dial gauge, spindle, pointer, and magnetic stand. It emphasizes the importance of proper calibration, which involves positioning the gauge correctly and zeroing the scale. The measurement process is illustrated through a step-by-step guide, demonstrating how to mark a component, rotate it, and read the maximum deviation. This overview aims to equip viewers with the knowledge to utilize the dial indicator accurately.

Takeaways

- 😀 Dial gauges are used to measure various mechanical parameters, including shaft run-out and alignment.

- 🔍 The dial gauge features a special mechanism that amplifies small movements of the spindle.

- 📏 The main components of a dial gauge include the dial itself, support beam, locking mechanism, and magnetic stand.

- 🔧 Calibration is essential; the outer ring of the gauge allows for adjustments to ensure the pointer reads zero.

- ⚙️ The pointer indicates measurements in millimeters, with a precision of 0.01 mm.

- 🔄 To measure run-out, position the dial gauge perpendicular to the surface being measured.

- ✏️ Mark the starting point on the rotor with chalk or a pen for reference during measurement.

- 🌀 Slowly rotate the component to observe the gauge's readings for run-out measurements.

- 📉 A run-out result of 0.04 mm indicates the level of deviation from a perfect circle.

- ❓ Viewers are encouraged to ask questions or provide suggestions about using the dial indicator in the comments.

Q & A

What is the primary function of a dial gauge?

-The primary function of a dial gauge is to measure small movements and deviations in components, such as runout, alignment, and flatness of shafts.

What components make up a typical dial gauge unit?

-A typical dial gauge unit includes the dial gauge itself, a Gug beam lock, a magnetic stand, a pointer, a stem, a spindle, and an outer ring for calibration.

How does the mechanism of a dial gauge work?

-The dial gauge works by amplifying small movements of the spindle, which are displayed on the indicator pointer, allowing for precise measurements.

Why is it important to position the dial gauge perpendicular to the surface being measured?

-Positioning the dial gauge perpendicular to the surface ensures accurate measurements and prevents any angular errors that could affect the readings.

What should you do to calibrate the dial gauge before use?

-To calibrate the dial gauge, set the outer ring so that the pointer indicates zero when the gauge is at the starting point of measurement.

What is runout, and why is it significant in automotive measurements?

-Runout refers to the deviation of a rotating component from its true circular path. It is significant because excessive runout can lead to uneven wear and operational issues in automotive parts.

How can you visually track the runout measurement during the procedure?

-You can track the runout measurement by marking the starting point on the component and observing how far the pointer moves as you rotate the component.

What does a maximum runout measurement of 0.04 mm indicate?

-A maximum runout measurement of 0.04 mm indicates that the component's surface has a small irregularity that may affect its performance, but it is generally within acceptable limits.

What tools can be used to mark the starting point on the rotor?

-Tools such as chalk, a pencil, or a pen can be used to mark the starting point on the rotor for tracking the measurement.

What should viewers do if they have questions about using a dial gauge?

-Viewers are encouraged to write their questions or suggestions in the comments section for further clarification or guidance.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Cara Membaca Dial Indikator

How Do You Read Measurements Taken With Dial Calipers?

How To Use a Pinion Depth Gauge

Cara setting benda kerja di mesin CNC milling mitsubishi M70

How to Use a Multimeter for Beginners - How to Measure Voltage, Resistance, Continuity and Amps

Electronic Basics #1: The Multimeter

5.0 / 5 (0 votes)