(Nanorush 2024) How LEDs are Made : The Journey from Start to Bright!

Summary

TLDRDrin Abdullah, a scientist at the Institute of Nano-Opto Electronics Research and Technology at University Science Malaysia, discusses the fascinating world of LEDs (Light Emitting Diodes). He explains how LEDs are used in everyday devices and how they are more energy-efficient compared to traditional lighting. He delves into the structure, composition, and fabrication process of LED chips, focusing on materials like gallium nitride, and their role in generating blue light. The process involves intricate steps like deposition, photolithography, and etching, all aimed at creating efficient light sources for a sustainable future.

Takeaways

- 💡 LED technology is essential in daily life, powering devices like smartphones, laptops, smartwatches, and even cars.

- 🌍 About 25% of the world's electricity is used for lighting, making energy-efficient lighting technologies, like LEDs, critical.

- 🔦 LEDs have various applications, from home lighting to public transport, traffic lights, entertainment, and even indoor gardening.

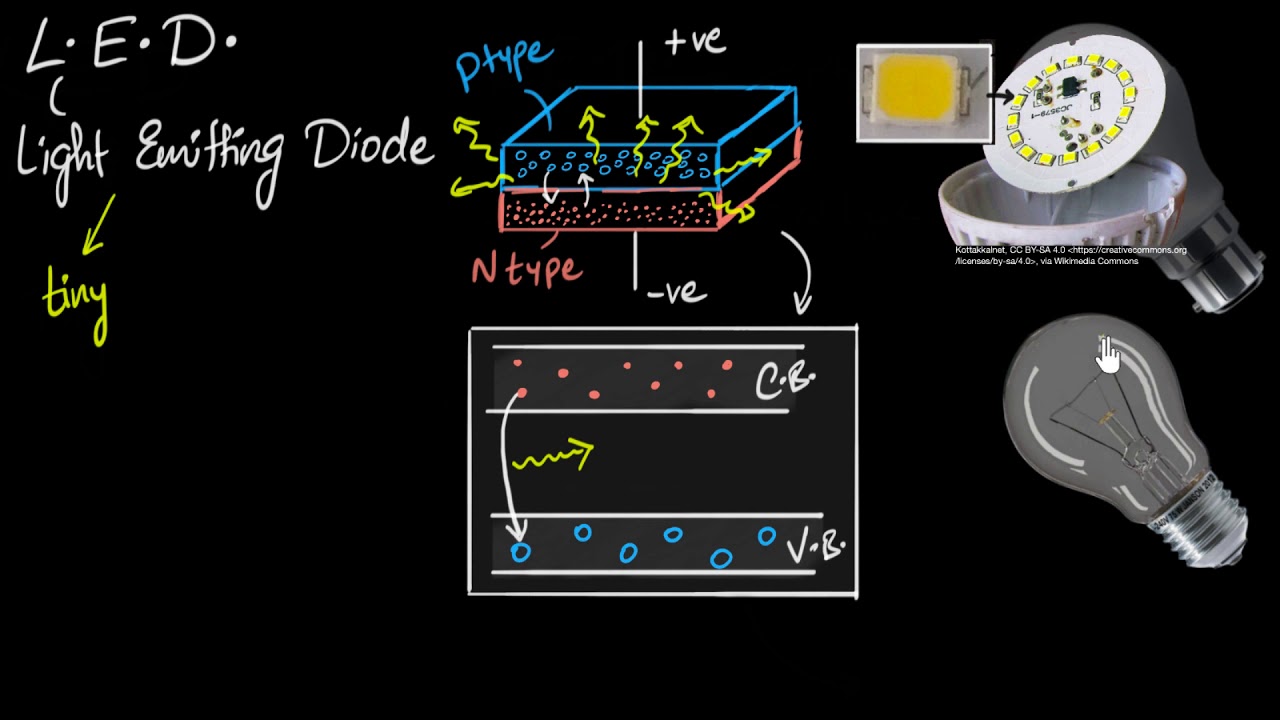

- 🟨 The yellow square components inside an LED bulb are LEDs, with the yellow phosphor layer converting blue light into white light.

- 🔵 Many white LEDs actually emit blue light, which is then transformed into white light by the phosphor layer on top.

- 📏 The structure of an LED is made up of multiple layers, including metals and semiconductors like gallium nitride, which emits blue light.

- 🔬 Gallium nitride layers can be adjusted to emit different colors of light, including green and ultraviolet, by modifying the indium content.

- 🏭 LED production involves a complex fabrication process, including wafer growth, metal deposition, photolithography, and etching.

- 📐 Precise control of layer thickness, temperature, and materials is essential for producing high-quality LED chips with efficient light output.

- 🌟 In 2023, the institute developed a highly efficient white LED that exceeded industry standards, producing over 200 lumens per watt.

Q & A

What is Dr. Drin Abdullah's research focus?

-Dr. Drin Abdullah's research focuses on optics and photonics, with a specific interest in photonic devices such as light-emitting diodes (LEDs).

How much of the world's electricity is used for lighting?

-About a quarter of the world's electricity is used for lighting, which is a significant portion of global energy consumption.

What are some common applications of LEDs mentioned in the talk?

-LEDs are used in lighting homes, streets, car headlights, public transport, traffic lights, stage lighting for entertainment and sports, and even as artificial sunlight for growing vegetables indoors.

What is the primary component inside an LED bulb that produces light?

-The primary component inside an LED bulb that produces light is the LED chip, which is often made from a synthetic semiconductor material like gallium nitride (GaN).

How does the phosphor layer in an LED bulb contribute to the light production?

-The phosphor layer absorbs blue light emitted by the LED chip and converts it into yellowish light. The combination of blue and yellow light creates the white light we see.

What are the two common types of LED packages mentioned?

-The two common types of LED packages mentioned are SMD LEDs (Surface Mount Device) and DIP LEDs (Dual In-Line Package).

What is the role of the multiquantum well (MQW) layer in an LED?

-The MQW layer is the region where positive and negative charge carriers recombine, efficiently producing light. The composition of the MQW layer determines the color of the emitted light.

What are some materials used in the electrodes of an LED chip?

-The electrodes of an LED chip are typically made from metals like chromium, nickel, gold, and titanium, which allow for the flow of charge in the LED chip.

What is the significance of the MOCVD process in LED manufacturing?

-The Metal Organic Chemical Vapor Deposition (MOCVD) process is crucial in growing high-quality semiconductor layers, such as gallium nitride (GaN), with precise thicknesses and compositions. This process is essential for producing efficient LEDs.

How do LEDs compare to traditional tungsten lamps in terms of efficiency?

-LEDs are much more efficient than tungsten lamps because they primarily produce light instead of heat. In contrast, tungsten lamps generate light by heating a filament, which results in a significant loss of energy as heat.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Light Emitting Diode (LED) Explained (Working, Advantages and Types of LED Explained)

LED light Emitting Diode (Unit 3 Special purpose diode and Transistors) in हिन्दी

What is LED Light Emitting Diode | How Does LED Works | Electronic Devices & Circuits | Engineering

DIODES! All Sorts of Them and How They Work (ElectroBOOM101-010)

How LED Works - Unravel the Mysteries of How LEDs Work!

LED working & advantages | Semiconductors | Physics | Khan Academy

5.0 / 5 (0 votes)