Mechanics of Materials Problem: 1-80

Summary

TLDRThis video script discusses a mechanics of materials problem involving a cotter pin holding two rods together. It calculates the smallest thickness of the pin and the diameter of the rods using steel's failure normal stress (500 MPa) and shear stress (375 MPa). A factor of safety of 2.5 for tension and 1.75 for shear is applied. The script derives the allowable normal stress (200 MPa) and diameter (13.8 mm), then calculates the allowable shear stress (214.29 MPa) and pin thickness (7 mm), providing a comprehensive solution.

Takeaways

- 🔩 The cotter pin is used to hold two rods together in a mechanics of materials probe.

- 🎚 The material used is steel with a normal stress failure of 500 MPa and shear stress failure of 375 MPa.

- 🔒 A factor of safety of 2.5 is used in tension and 1.75 in shear.

- 📏 The smallest thickness 'T' of the pin and the smallest diameter 'D' of the rods need to be determined.

- 📈 The normal force is 300 kN acting upwards in the normal direction.

- 📉 The allowable normal stress is calculated as 200 MPa using the factor of safety.

- 🔍 The diameter 'D' of the rods is found to be 13.8 mm when considering the normal stress.

- ✂️ Shear force is considered with two shears, one on each side of the pin.

- 📏 The allowable shear stress is calculated as 214.29 MPa using the factor of safety.

- 📐 The thickness 'T' of the cotter pin is determined to be 7 mm when considering the shear stress.

Q & A

What is the purpose of the cotter pin in the mechanics of materials probe?

-The cotter pin is used to hold two rods together in the mechanics of materials probe.

What material are the parts made of, and what are their failure stresses?

-The parts are made of steel with a failure normal stress of 500 megapascals and a failure shear stress of 375 megapascals.

What are the factors of safety used for tension and shear?

-The factor of safety used for tension is 2.5, and for shear, it is 1.75.

How is the normal stress calculated in the probe?

-The normal stress is calculated by dividing the failure normal stress by the factor of safety in tension, which is 500 megapascals divided by 2.5.

What is the allowable normal stress determined to be?

-The allowable normal stress is determined to be 200 megapascals.

How is the diameter of the rods calculated?

-The diameter of the rods is calculated using the formula for normal stress, which is T over the area (pi times diameter squared divided by 4), and solving for diameter.

What is the calculated diameter of the rods in millimeters?

-The calculated diameter of the rods is 13.8 millimeters.

How many shear forces are there, and in which direction do they act?

-There are two shear forces, one on each side of the cotter pin, acting in opposite directions.

What is the shear stress calculation based on?

-The shear stress calculation is based on the failure shear stress divided by the factor of safety in shear.

What is the allowable shear stress?

-The allowable shear stress is calculated to be 214.29 megapascals.

How is the thickness of the cotter pin determined?

-The thickness of the cotter pin is determined using the formula for shear stress, which is shear force over the area, and solving for thickness.

What is the final answer for the thickness of the cotter pin in meters?

-The final answer for the thickness of the cotter pin is 0.007 meters or 7 millimeters.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

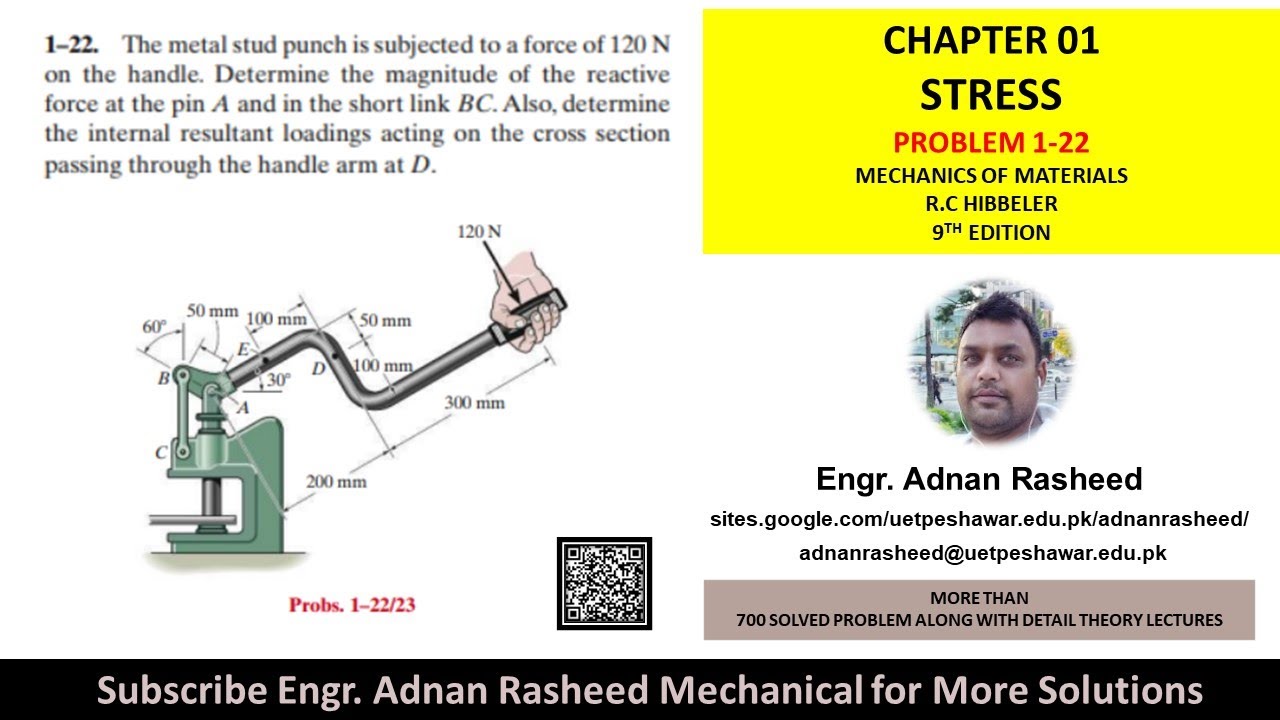

Determine internal resultant loading | 1-22 | stress | shear force | Mechanics of materials rc hibb

Variaciones Combinaciones Permutaciones Ejercicios Resueltos Nivel 2A

The rigid bar AB, attached to two vertical rods as shown in

LAKUKAN INI SEBELUM PASANG PENANGKAL PETIR RUMAH !!!

Nashik Accident: चालत्या टेम्पोत डान्स मग शरीरात सळ्या घुसून ८ मृत्यू, नाशिकच्या अपघातात चूक कुणाची?

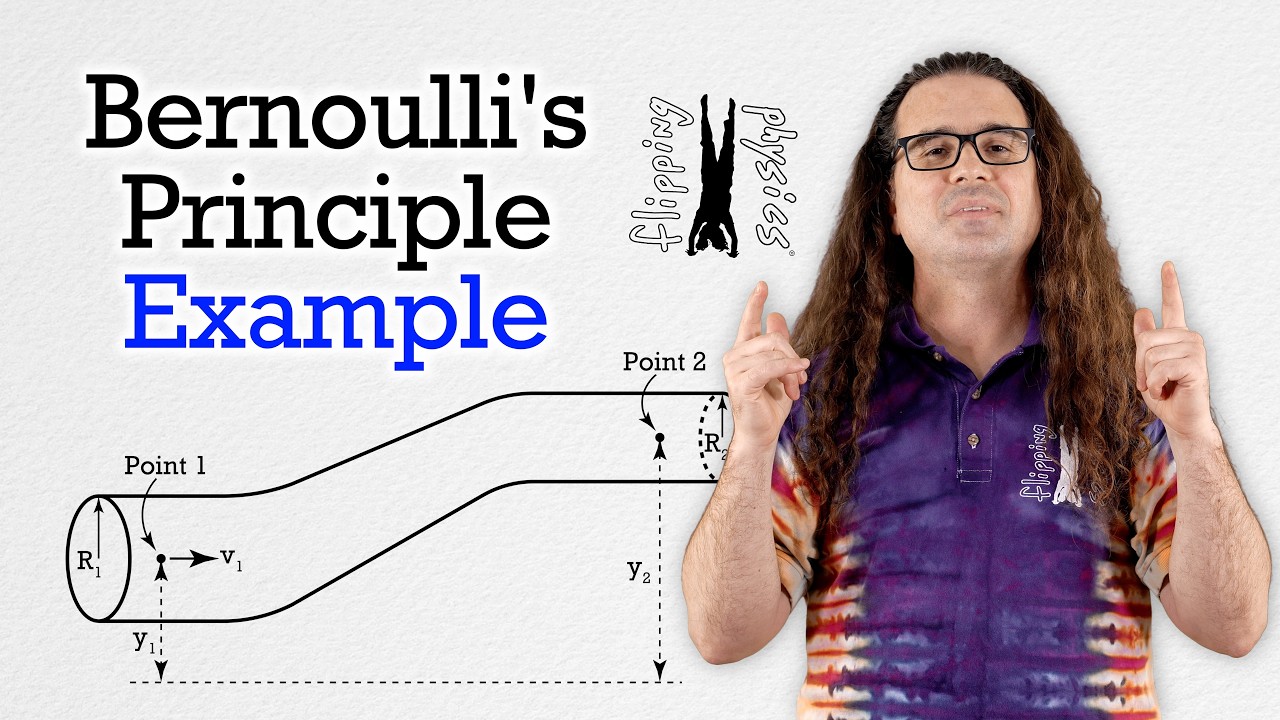

Solving Fluid Flow with Bernoulli’s Equation

5.0 / 5 (0 votes)