Mistake Proofing: Achieving Zero Defects

Summary

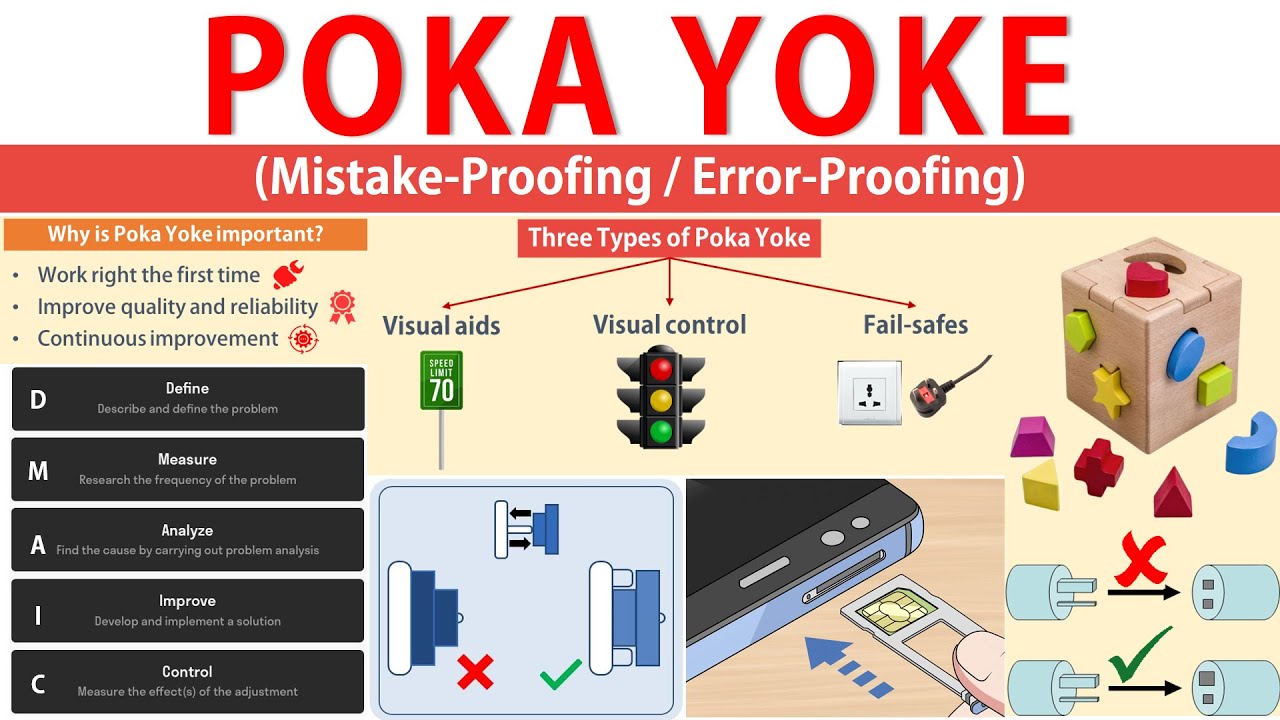

TLDRMistake-proofing, or 'Poke Yoke', is a methodology developed by Dr. Shigeo Shingo to achieve zero defects in manufacturing. It operates on the premise of preventing errors from occurring and swiftly identifying their causes if they do. This approach requires a shift from the traditional belief in human fallibility to implementing strategies that minimize mistakes. Companies practicing mistake-proofing adopt a no-blame policy, encouraging workers to report errors to facilitate quick detection and correction. Commonly used tools include guide pins, error detection alarms, limit switches, counters, and checklists, ranging from simple to sophisticated.

Takeaways

- 🔍 Mistake Proofing, or Poka-Yoka, is a methodology aimed at achieving zero defects in manufacturing processes.

- 🇯🇵 Developed by Dr. Shigeo Shingo, a renowned Japanese manufacturing expert, this approach has been widely adopted in the industry.

- 🛠 It is applied in two primary ways: to prevent errors from happening and to detect and correct them quickly if they do occur.

- 🔄 This methodology challenges the traditional mindset that mistakes are inevitable due to human fallibility.

- 👥 It acknowledges that people are prone to errors but seeks innovative ways to minimize them.

- 🙅♂️ Companies practicing mistake proofing operate on a 'no blame' policy, encouraging workers to report mistakes without fear of repercussions.

- 🔔 The process begins by asking three critical questions: Has an error occurred? If so, why? How can it be prevented from recurring?

- 💡 Despite some implementations involving advanced technology, many mistake proofing solutions are surprisingly simple and cost-effective.

- 🔩 Common mistake proofing devices include guide pins, rails, error detection alarms, limit switches, counters, and checklists.

- 📝 A printed checklist is one of the simplest tools used to ensure all necessary steps in a process are completed correctly.

Q & A

What is mistake proofing or poke yoke?

-Mistake proofing or poke yoke is a methodology aimed at achieving zero defects, developed by Dr. Shigeo Shingo, a Japanese manufacturing expert. It involves preventing errors from occurring and ensuring that any errors that do occur are detected and their causes quickly identified.

How is mistake proofing used in practice?

-Mistake proofing is used to prevent errors from happening in the first place and, if they do occur, to ensure they are detected and their causes are quickly identified.

What is the traditional thinking that mistake proofing challenges?

-Mistake proofing challenges the conventional concept that people are fallible and will always make mistakes by implementing strategies to prevent errors and by encouraging a no-blame culture where mistakes are reported and addressed.

What is the first step in the mistake proofing process?

-The first step in the mistake proofing process is to answer three key questions: Has an error occurred? If so, why did it occur? What is the best way to prevent it from occurring again?

How does mistake proofing encourage workers to report mistakes?

-Mistake proofing operates under a policy of no blame, encouraging workers to report mistakes as they occur, which is the first step in identifying and preventing future errors.

What are some common mistake proofing devices mentioned in the script?

-Common mistake proofing devices include guide pins, rails, error detection alarms, limit switches, counters, and printed checklists.

What is the purpose of guide pins and rails in mistake proofing?

-Guide pins, rails, and similar devices are used to ensure that work or a tool is properly aligned, preventing misalignment errors.

How do error detection alarms contribute to mistake proofing?

-Error detection alarms, such as buzzers and flashing lights, alert workers to errors, allowing for immediate detection and correction.

What is the role of limit switches in mistake proofing?

-Limit switches are used to ensure the correct placement of a tool or part, preventing errors related to improper positioning.

How do counters help in mistake proofing?

-Counters guarantee that the correct number of events have occurred in a given process, preventing errors due to missed or extra steps.

Why are printed checklists considered a simple mistake proofing device?

-Printed checklists are simple and effective mistake proofing devices displayed at workstations to ensure that all necessary steps in a process or setup procedure have been completed.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

Poka Yoke (Error Proofing) - Meaning, Concept, Types, Stages, & Implementation Explained.

Headteachers talk about their experiences of Poverty Proofing

Learn Toyota's 8 Step Practical Problem Solving Methodology

What is Value Analysis? | Value Engineering

2023 Unity VR Basics - Poke Interactor

[Toyota Production System] Jidoka: Avoiding Simple Mistakes Through Poka-yoke Device

5.0 / 5 (0 votes)