Mengenal dan Belajar BOILER/Ketel uap

Summary

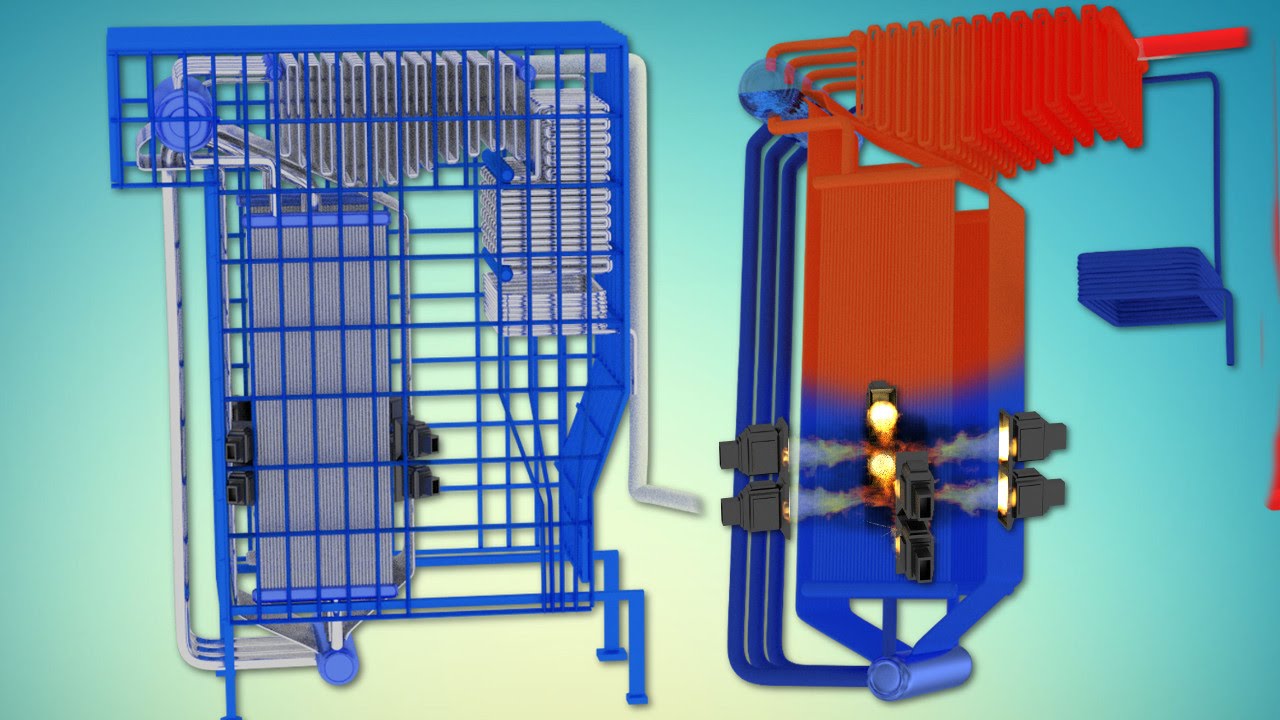

TLDRThis script explains the function of a boiler, a thermal engineering machine that converts chemical energy into work by heating water to produce steam. It details the components of a boiler, the process of fuel combustion, and the transfer of heat to water to create steam. The script also discusses the use of steam in industries, the types of fuels, and the difference between saturated and superheated steam, emphasizing the importance of superheated steam in turbine operation.

Takeaways

- 🔥 A boiler is a thermal engineering device that transfers chemical energy into work or mechanical energy by heating water to produce steam.

- 🌡️ The steam generated is used for various industrial purposes, including heating processes and driving turbines.

- 🏭 The heat from the combustion of fuel in the boiler is transferred to water flowing through pipes, causing it to vaporize and create steam.

- 🌳 Various types of fuels can be used in boilers, with coal being a common choice in industrial applications.

- 🔧 The boiler consists of different components, each with a specific function, such as the pulverizer for crushing coal, and the furnace for combustion.

- 💧 The deaerator removes gases like oxygen and carbon dioxide from the water to prevent corrosion and improve the efficiency of steam production.

- 🔄 The economizer uses waste heat from the exhaust gases to preheat the boiler feed water, improving the overall thermal efficiency.

- 🔥 The furnace is where the actual combustion of fuel occurs, providing the heat source for the water in the pipes to turn into steam.

- 🔁 The steam drum separates saturated steam from water, with the steam then being superheated to become superheated steam, which is used to drive turbines.

- ♻️ The condenser plays a role in the cooling and condensation of the steam after it has passed through the turbine, returning water to its liquid state for reuse.

- 🌐 The entire process within the boiler is designed to efficiently convert the chemical energy of the fuel into mechanical energy through the production and use of steam.

Q & A

What is the primary function of a boiler?

-A boiler is a thermal engineering machine that transfers the chemical energy of a fuel source into heat, which is then used to heat water to produce steam. This steam is used for various purposes in a factory.

What are some common uses of steam in industries?

-Steam is used in various industrial processes such as power generation, heating, and in some manufacturing processes like autoclaves for curing composites and in steam turbines for electricity production.

What kind of fuel is commonly used in boilers?

-The script mentions that coal is used as a fuel source in this particular boiler. However, other fuels such as natural gas, oil, or biomass can also be used.

How does a pulverizer contribute to the boiler's operation?

-A pulverizer is used to crush coal into fine particles so that it can mix well with air and burn efficiently in the boiler's combustion chamber.

What is the role of the deaerator in the boiler system?

-The deaerator is used to remove gases, particularly oxygen and carbon dioxide, from the feedwater to prevent corrosion and improve the efficiency of the boiler.

What is the purpose of the economizer in a boiler?

-The economizer is a series of pipes that preheat the boiler feedwater using waste heat from the combustion gases, thus improving the overall efficiency of the boiler.

What does the steam drum do in a boiler?

-The steam drum stores heated water and separates water from steam after the heating process in the boiler. It also helps in water circulation within the boiler.

How is heat transferred in the boiler to produce steam?

-Heat is transferred in the boiler through radiation, conduction, and convection. Radiation occurs as heat from the flames is absorbed by the water walls. Conduction happens as heat travels through the pipe walls into the water, and convection is the transfer of heat by the movement of water molecules.

What is the difference between saturated steam and superheated steam?

-Saturated steam is steam that is in equilibrium with water at a certain pressure and temperature, meaning it contains some liquid droplets. Superheated steam, on the other hand, is steam that has been heated above the saturation temperature, thus having no liquid content and being at a higher temperature, which is ideal for driving turbines.

Why is superheated steam preferred for turbine use?

-Superheated steam is preferred for turbines because it has a higher temperature and energy content, which results in more efficient energy conversion in the turbine and reduces the likelihood of steam condensation within the turbine blades.

What is the purpose of the reheat process in a power plant?

-The reheat process involves passing the steam through the Richter section of the boiler after it has done work in the high-pressure turbine. This process increases the steam temperature without affecting its pressure, which is then used in the intermediate and low-pressure turbines for further power generation.

How does the condenser contribute to the boiler's water cycle?

-The condenser cools the steam from the low-pressure turbine, turning it back into water, which is then returned to the boiler through a feedwater pump to maintain the water level and continue the steam production cycle.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级5.0 / 5 (0 votes)