📗 Qué es la SERIGRAFIA y COMO SE LLEVA A CABO - DICCIONARIO de Diseño Gráfico Trino

Summary

TLDRIn this video, the process of screen printing (serigraphy) is explored in detail. It covers the basics of the method, which involves printing designs onto various materials using ink and silk. The video explains each step, from creating a design using graphic software to transferring it onto a screen frame using light-sensitive emulsions. The tutorial also demonstrates the application of the design onto a t-shirt, highlighting the importance of using multiple screens for multi-color prints. The process concludes with drying the ink and ensuring the design is long-lasting on the fabric.

Takeaways

- 😀 Serigraphy is a printing method that uses ink and silk to reproduce images on various materials, especially t-shirts.

- 😀 The process starts with creating the design, which can be done by hand or using graphic design software like Illustrator, Photoshop, or CorelDraw.

- 😀 The design is printed in black on transparent paper, called a photolith, which will be used to transfer the design onto the screen.

- 😀 The design from the photolith is transferred to a silk screen frame through a process called 'revealing', using a photosensitive emulsion.

- 😀 A special screen, made from silk or similar material, is stretched onto a frame made from aluminum or wood, depending on budget.

- 😀 The photosensitive emulsion reacts to light and hardens where exposed, allowing the unexposed areas to wash away, leaving the design on the screen.

- 😀 Once the design is transferred to the screen, heat is applied to dry the emulsion and prepare the screen for printing.

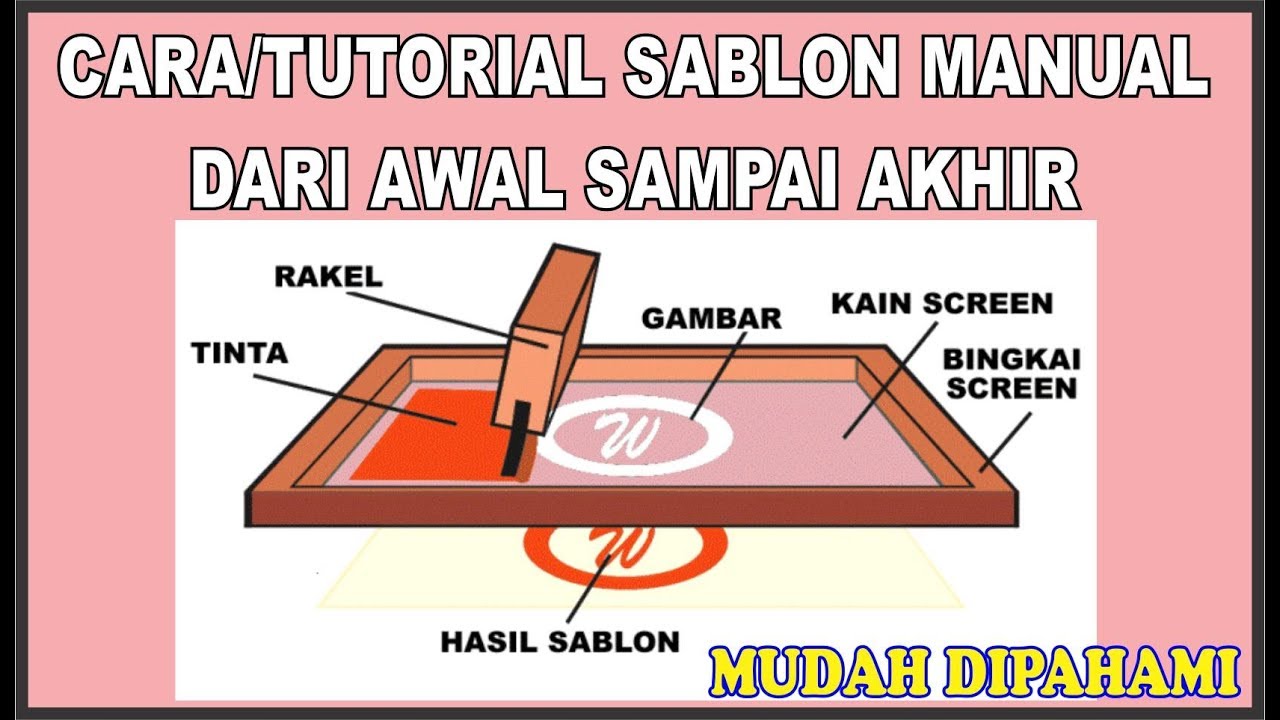

- 😀 For printing, the screen is placed over the t-shirt, and ink is spread across the design using a tool called a squeegee.

- 😀 The ink is pushed through the screen and onto the t-shirt in the areas where the design has been etched, creating the print.

- 😀 After printing, the shirt is heat-treated to set the ink, ensuring the design will not fade after washing.

- 😀 Multi-color designs require separate screens for each color, with each color being printed individually in layers.

Q & A

What is screen printing, and how is it defined in the video?

-Screen printing is a method of printing and reproducing images using ink and silk. It involves transferring a design onto a material, usually fabric or paper, using a stencil or screen. The term comes from the words 'ser' meaning silk and 'grafos' meaning writing.

What types of materials can screen printing be used on?

-Screen printing can be used on a variety of materials, including fabrics (like t-shirts), promotional products, different types of paper, and even wood.

What is the first step in the screen printing process?

-The first step in screen printing is creating the design that will be printed. This can be done manually or using graphic design software such as Illustrator, Photoshop, or CorelDraw.

What is a 'fotolito,' and why is it important in screen printing?

-A 'fotolito' is a black-and-white printed image that serves as the stencil for the screen printing process. It's printed on transparent paper, and the areas printed in black will be the parts that are transferred onto the material being printed.

How is the design transferred from the fotolito to the screen?

-The design from the fotolito is transferred to the screen through a process called 'revelado' or exposure. A frame, typically made of aluminum or wood, is coated with a photosensitive emulsion. The fotolito is placed over the frame, and the frame is exposed to light, causing the emulsion to harden in areas not blocked by the black ink of the fotolito.

What happens after the frame is exposed to light?

-After exposure, the emulsion that was not exposed to light (where the black areas of the fotolito blocked the light) is washed away with water, revealing the design on the screen.

What is the purpose of applying heat after washing the frame?

-Heat is applied after washing the frame to ensure the emulsion dries and becomes solid, which is essential for the printing process. This helps to make the design permanent on the screen.

What happens during the actual screen printing process on a t-shirt?

-During screen printing, a t-shirt is placed underneath the prepared screen, and ink is spread over the design area. The ink is pushed through the screen using a squeegee, transferring the design onto the shirt. The screen is lifted, and the printed design is now on the shirt.

How is the ink fixed on the t-shirt after printing?

-After the ink is applied to the t-shirt, it is dried using heat, often with a heat press, to ensure the ink bonds well with the fabric and doesn't wash off after the first wash.

How is screen printing done when a design has multiple colors?

-For multi-color designs, separate screens are used for each color. Each color is printed one by one, with a new screen for each color layer. The process is repeated until all colors are applied to the t-shirt.

Outlines

此内容仅限付费用户访问。 请升级后访问。

立即升级Mindmap

此内容仅限付费用户访问。 请升级后访问。

立即升级Keywords

此内容仅限付费用户访问。 请升级后访问。

立即升级Highlights

此内容仅限付费用户访问。 请升级后访问。

立即升级Transcripts

此内容仅限付费用户访问。 请升级后访问。

立即升级浏览更多相关视频

KEGIATAN P5 PERAKTEK MENYABLON | pkbm bina warga

Ultimate Screen Printing Guide: Screen Creation Techniques

Materi Seni Budaya Kelas 9 || Seni Grafis

Cara Pisah Warna di Photoshop Untuk Film Sablon Pemula ( 6 warna 4 warna 2 warna )

Screen Print with me ✸ HOW I BURN A SCREEN ✸ Printing at home ✸

SABLON KAOS MANUAL PRAKTIS DARI AWAL HINGGA AKHIR DIJAMIN BISA

5.0 / 5 (0 votes)