ทำเวฟ125 เป็น326cc. 76/4valve (SUBTITLE) #wave

Summary

TLDRThe video documents the process of custom building a 326cc racing engine for a customer in Vietnam. It shows welding an extended stroke crankcase, machining it to fit a larger 76mm piston, adapting parts from various Honda bikes, and test fitting the engine. Details are provided on technical specifications like increasing the stroke length 14mm to 126mm. The goal is creating a high-revving, high-horsepower engine for motocross racing by utilizing a mix of components from the builder's experience and the customer's requests.

Takeaways

- 😊 The customer is located in Vietnam and ordered an custom engine build

- 🔧 The build combines parts from various Honda motorcycles to create a high-performance engine

- ⚙️ The crankshaft stroke length was increased by 14mm for more power

- 👷 Welding and machining is required to join the Yamaha cylinder block to the Honda crankcase

- 🛠 The cylinder block is from an Exciter air-cooled engine

- ⛏ The engine displacement is increased to 326cc

- 📏 Precise measurement is needed to align the crankshaft center line when welding sides

- 🧰 Edge chamfering of cylinder bore done to ease piston ring insertion

- 🚗 The finished engine has smooth crank rotation

- ✈️ The custom 326cc engine was shipped overseas to the customer in Vietnam

Q & A

What parts are being combined to create this custom engine?

-A Hercules alloy cylinder block, Yamaha upper end, Honda Wave 125 crankcase, 76mm piston, extended stroke crankshaft, RXZ connecting rod, and Exciter cylinder block for the air pump.

What is the purpose of welding the crankcase?

-To extend the stroke length by 14mm total to match the custom 76mm piston.

How is the front center found when welding the crankcase?

-By attaching the welded crankcase to the original crankcase and finding the center from that side before cutting.

Why use an air pump cylinder block?

-An air pump cylinder block doesn't use water for cooling. It relies on air flowing over cooling fins instead.

What is the total engine displacement?

-326cc

What modifications were made to the crankcase foot?

-It was concaved so the foot protrudes deeper in order to better support the 76mm piston.

What was the purpose of removing sharp edges from the cylinder jacket?

-To allow the piston rings to be inserted more easily.

How is the cooling achieved in this engine?

-Through air flowing over cooling fins rather than water.

When was the custom engine sent to the customer?

-It had already been sent by the time the video was posted.

What brands were used in creating this custom engine?

-Hercules alloy, Yamaha, Honda Wave 125, and Exciter.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Toyota 2JZ Engine Build - Full Start to Finish

I Built a Dark Academia Gaming Room

REVIEW JUJUR MOTOR CUSTOM|KEKURANGAN DAN KELEBIHAN

What is the best 1.8T Engine Setup?

JAJAL RISETAN 59 OPEN STROKE PENDEK DALAM NEGERI | CDUCKZ [YOGYAKARTA]

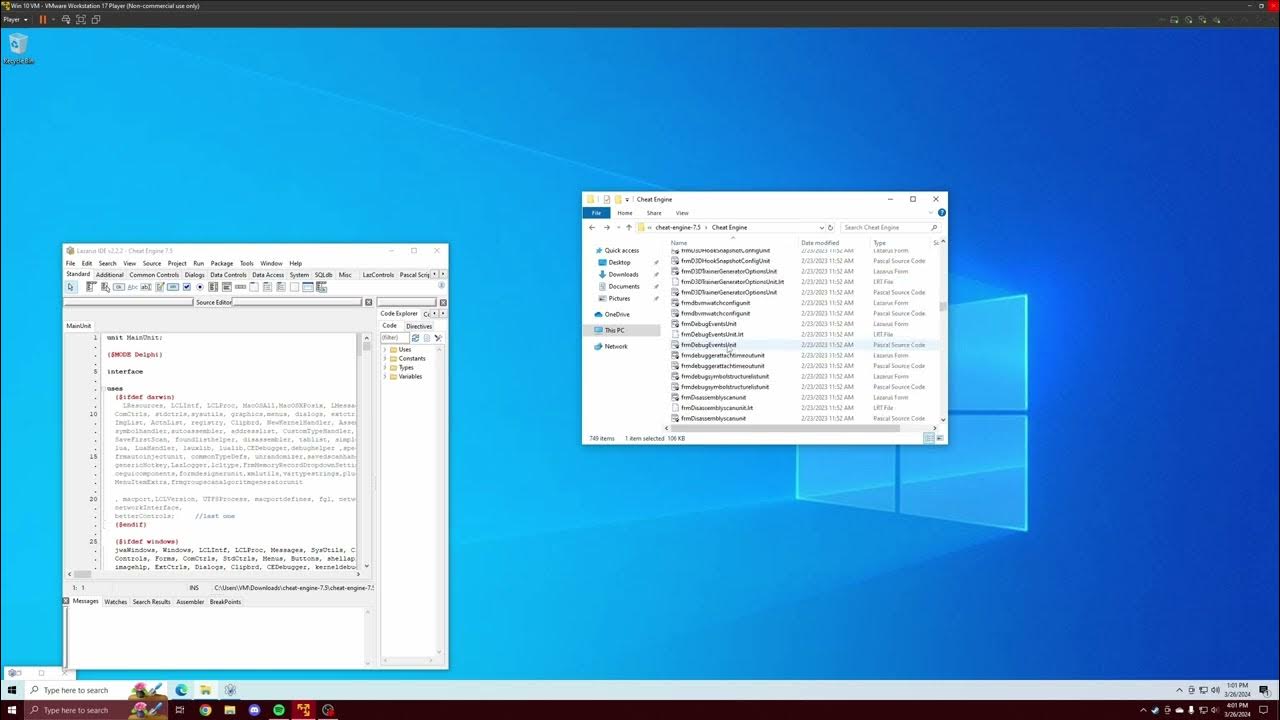

Cheat Engine Built From Source Tutorial | Driver | DBVM | VEH Debugger | Renaming | Error Correction

5.0 / 5 (0 votes)