Gears : Types and its Applications

Summary

TLDRThis video provides an in-depth exploration of various types of gears and their applications. It covers common gears like spur, helical, bevel, and worm gears, detailing their design, functions, and uses in industries like automotive, manufacturing, and energy. The video explains the advantages of each gear type, such as smooth motion and high load capacity, and highlights their role in mechanisms like clocks, electric screwdrivers, bicycles, and power stations. The video also touches on specialized gears like face gears and rack and pinion systems used in different machines and vehicles.

Takeaways

- 😀 Spur gears are the most common type of gears, known for their simplicity, economy, and lack of end thrust.

- 😀 Helical gears have teeth that are inclined to the axis of the shafts and are preferred for heavy-load applications, offering smoother, quieter motion than spur gears.

- 😀 Herringbone gears combine two helical gears placed side by side to counterbalance thrust loads and provide smooth power transmission.

- 😀 Bevel gears are used when shafts are at intersecting angles, and they come in different types such as straight bevel, spiral bevel, and hypoid bevel gears.

- 😀 Spiral bevel gears offer quieter operation and can handle more load compared to straight bevel gears, making them ideal for high-speed applications.

- 😀 Worm gears provide a right-angle power transmission and are used in applications requiring high reductions and quiet, smooth motion.

- 😀 Rack and pinion gears convert rotational motion to linear motion, commonly used in steering mechanisms in automobiles.

- 😀 External gears have teeth on the outer surface of a cylinder or cone, whereas internal gears have teeth on the inner surface.

- 😀 Face gears are used to transmit power at right angles and are less common in industrial applications.

- 😀 Each type of gear serves a distinct purpose, with specific applications in machines, vehicles, appliances, and heavy machinery, ensuring optimal performance based on the need for speed, load handling, and torque.

Q & A

What are spur gears and what are their primary advantages?

-Spur gears are gears with straight teeth that are parallel to the axis of the gear. Their primary advantages include simplicity in design, cost-effectiveness in manufacturing and maintenance, and the absence of end thrust, which imposes only radial loads on the bearings. They are commonly used for speed reduction or increase and torque multiplication.

In what applications are spur gears typically used?

-Spur gears are used in various mechanical applications such as clocks, electric screwdrivers, washing machines, blenders, and oscillating sprinklers. They are also found in aircraft engines, railway trains, and slow-speed vehicles like bicycles, as well as in high torque, low-speed drives like ball mills and sugar mills.

What distinguishes helical gears from spur gears?

-Helical gears differ from spur gears in that their teeth are inclined to the axis of the shafts in the form of a helix. This results in smoother and quieter operation, allowing them to take higher loads compared to similarly-sized spur gears. However, helical gears also impose both radial and thrust loads on bearings, requiring thrust bearings.

What is a herringbone gear and what are its advantages?

-A herringbone gear is essentially two helical gears placed side by side, often called double helical gears. The key advantage of herringbone gears is that they counterbalance the thrust loads, resulting in no thrust loading on the bearings. Additionally, they transmit power smoothly and efficiently, making them suitable for heavy machinery.

What are bevel gears and where are they commonly used?

-Bevel gears are gears that connect shafts whose axes are either parallel or intersecting in the same plane. They are often used in differential drives, particularly in automobiles, where they transmit power to two axles spinning at different speeds. Bevel gears are also used in hand drills to convert vertical rotation to horizontal and are important in rotorcraft drive systems.

What are the different types of bevel gears?

-Bevel gears come in various types, including straight bevel gears (with conical pitch surfaces and straight teeth), spiral bevel gears (which are quieter and can handle more load), zerol bevel gears (which have curved teeth arranged to create an effective spiral angle of zero), and hypoid bevel gears (with hyperbolic pitch surfaces).

How do spiral bevel gears differ from straight bevel gears?

-Spiral bevel gears have spiral-shaped teeth, while straight bevel gears have straight teeth that taper toward the apex. Spiral bevel gears are quieter and can handle higher loads compared to straight bevel gears, making them more suitable for high-speed and high-load applications.

What is the purpose of worm gears, and where are they typically used?

-Worm gears are used to transmit power at a 90-degree angle, often with high reductions in speed. They are quiet, vibration-free, and provide smooth output, which makes them ideal for applications requiring precise motion control, such as in conveyors, elevators, and some automotive gear systems.

What is the function of rack and pinion gears?

-Rack and pinion gears convert rotational motion into linear motion. The pinion gear meshes with the rack, causing the rack to move in a straight line. This mechanism is commonly used in automobile steering systems to convert the rotational motion of the steering wheel into the left-to-right motion of the tires.

What is the difference between external and internal gears?

-The difference between external and internal gears lies in the location of the teeth. External gears have teeth formed on the outer surface of a cylinder or cone, while internal gears have teeth formed on the inner surface of a cylinder or cone. External gears typically mesh with internal gears or other external gears to transmit motion.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

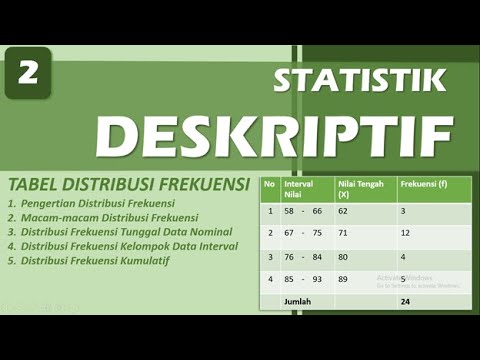

DISTRIBUSI FREKUENSI - STATISTIK DESKRIPTIF | BAB 2

Kuliah Elektronika Daya Pokok Bahasan Rangkaian Inverter

Cholinergic agonists || Mechanism, actions, side effects & uses

Barang Tambang #1 (Pengertian dan Klasifikasi Barang Tambang)

Different Types of Gears and their Uses explained | 3d animation

Business Process Modeling (BPM): Definisi, Manfaat dan Teknik

5.0 / 5 (0 votes)