Fluid Flow through a T-Shaped Pipe | CFD Analysis | ANSYS Fluent | ANSYS CFD Tutorials

Summary

TLDRThis CFD tutorial demonstrates the step-by-step process of analyzing a T-shaped pipe using Fluent. The tutorial covers importing geometry, defining fluid and solid materials, meshing, setting boundary conditions for inlets and outlets, and running the simulation. It highlights the importance of correct material selection, mesh refinement, and initialization settings. Results are visualized through streamlines and contour plots to analyze velocity and pressure variations. The tutorial concludes with a note on solution convergence, encouraging users to adjust iterations for more refined results. Perfect for anyone looking to enhance their CFD skills and understanding of flow dynamics in piping systems.

Takeaways

- 😀 The session covers the CFD analysis of a T-shaped pipe with two inlets and one outlet.

- 😀 The process begins by importing pre-made geometry and adding fluid to the model.

- 😀 The user creates two solid bodies, one for the pipe and one for the fluid, renaming them as 'wall' and 'fluid'.

- 😀 Mesh generation is performed with an element size of 0.01m, and the inlet, outlet, and wall surfaces are named accordingly.

- 😀 After meshing, the setup includes defining material properties such as air for fluid and steel for solids.

- 😀 Boundary conditions are set with different velocities for Inlet 1 (3.2 m/s) and Inlet 2 (2.6 m/s).

- 😀 The user chooses 'water liquid' as the material for the fluid, and 'steel' for the wall material in Fluent.

- 😀 Initialization of the solution is done using standard initialization, with computations done across all zones.

- 😀 The number of iterations for the calculation is set to 500, though the solution has not yet converged.

- 😀 The results are visualized with contour plots for pressure and velocity, showing variations in flow speed and pressure across the model.

Q & A

What is the primary goal of the session in this tutorial?

-The primary goal of the session is to analyze a T-shaped pipe for Computational Fluid Dynamics (CFD) using ANSYS Fluent.

How is the geometry of the pipe created in the tutorial?

-The geometry is already made and imported into the software. The user uses the 'Tools' menu to fill the inner surface of the pipe, then renames the parts into 'Wall' and 'Fluid' before proceeding with meshing.

What steps are involved in creating the mesh for the geometry?

-First, the user changes the element size to 0.01 meters, then generates the mesh. Afterward, the user names the inlet, outlet, and wall surfaces for further simulation steps.

What are the specific boundaries assigned to the pipe in the tutorial?

-The boundaries assigned to the pipe are the 'Inlet', 'Outlet', and 'Wall'. The inlet velocities are set as 3.2 m/s for Inlet 1 and 2.6 m/s for Inlet 2, while the wall is assigned as a boundary surface.

What material properties are used for the simulation?

-The fluid is assigned as water (liquid), and the solid material is assigned as steel, using the Fluent database for both materials.

What boundary conditions are applied to the inlets and outlets?

-For Inlet 1, a velocity of 3.2 m/s is applied, and for Inlet 2, a velocity of 2.6 m/s is used. The outlet is set at a pressure-based boundary condition, and the wall is treated as a no-slip surface.

What is the purpose of initializing the simulation in Fluent?

-Initialization ensures the solver starts from a reasonable initial guess for the solution. In this case, the 'standard initialization' from all zones is used to compute the initial conditions.

How is the convergence of the simulation monitored?

-The user checks if the solution has converged. In this tutorial, the simulation is stopped before full convergence, with the option to increase iterations for more refined results.

What type of post-processing is done in the results section?

-The user checks velocity and pressure distributions using contours and streamlines. For example, the pressure is higher where the velocity is low, and vice versa, which helps analyze the flow behavior.

What is the significance of the velocity and pressure variations in the simulation?

-Velocity and pressure variations indicate how the fluid behaves at different points in the pipe. Higher velocity at one of the inlets leads to lower pressure in that region, which is important for understanding fluid dynamics in the T-shaped pipe.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

How to Thread Pipe; A Beginner's Tutorial

Membuat Desain Tipografi Simpel

Cara membuat filter air dari pipa paralon manual backwash

Scratch - Membuat Game Flappy Bird

Every Pipe Fitter Must Know This Pipe Fitting Techniques.

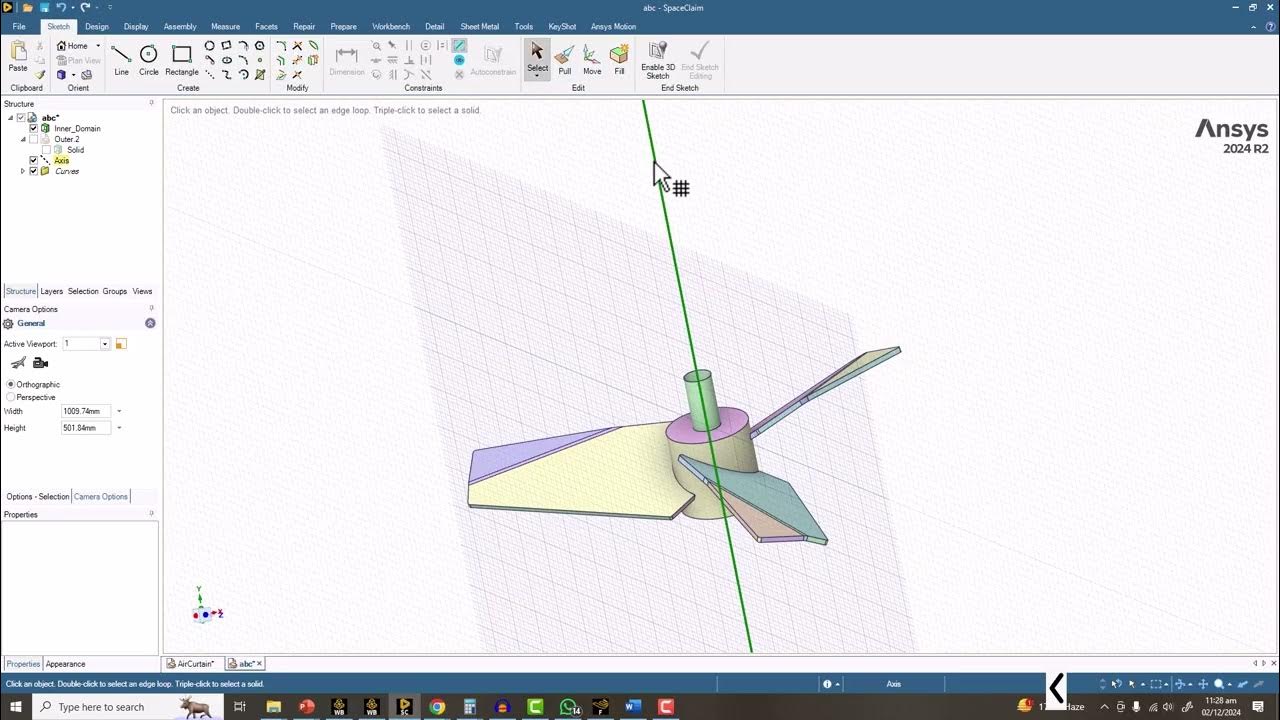

How to provide axis direction for tilted impeller in ANSYS Fluent 2024 R2 Part 2

5.0 / 5 (0 votes)