How a Bulk Carrier Works – Loading, Cargo, and Design Features

Summary

TLDRThis video explores the fascinating evolution of bulk carriers, essential cargo ships used to transport raw materials like grain, coal, and iron ore across the world's oceans. The script compares ancient Roman grain ships to modern bulk carriers, highlighting advancements in ship design, loading and unloading techniques, and cargo handling systems. It covers the operational aspects of these vessels, from loading grain at specialized terminals to unloading with onboard cranes. The video also delves into ship safety, structural integrity, and the vital role bulk carriers play in global trade, especially in feeding the world's population.

Takeaways

- 😀 Bulk carriers are specialized ships designed to transport unpackaged goods like grain, coal, and iron ore.

- 😀 Over 2,000 years ago, the Roman Empire used small wooden ships, called corbiters, to carry grains, while modern bulk carriers can carry up to 300,000 tons of cargo.

- 😀 Modern bulk carriers use powerful cranes and conveyor systems to load cargo in just hours, compared to the slow, manual loading of the past.

- 😀 Bulk carriers rely on vast cargo holds where goods like grain are poured directly, requiring even distribution for stability during transport.

- 😀 Loading techniques vary based on the cargo type, including homogeneous, alternate hold, and block hold loading methods.

- 😀 Weather conditions, especially rain, must be monitored when loading grain, as it can damage the cargo if not properly sealed.

- 😀 Once fully loaded, cargo holds are sealed with tape and hatch covers to prevent water from damaging the cargo during the voyage.

- 😀 Bulk carriers are dedicated to one type of cargo per voyage to prevent contamination between different goods.

- 😀 Upon arrival at the destination, bulk carriers unload cargo using onboard cranes or port Gantry cranes, often with clamshell buckets for grain.

- 😀 After unloading, the cargo holds are washed down and cleaned, sometimes requiring manual cleaning by workers due to confined spaces.

- 😀 Bulk carrier ships are equipped with advanced safety features and regular maintenance is crucial to prevent catastrophic failures due to corrosion and faulty components.

Q & A

What is a bulk carrier and what type of cargo does it transport?

-A bulk carrier is a specialized cargo ship designed to transport large quantities of unpackaged goods, such as grain, coal, iron ore, and steel coils.

How did the Roman Empire transport grain, and how does it compare to modern methods?

-The Romans used wooden ships called corbiters, around 30 meters long, carrying roughly 200 tons of cargo, loaded manually by hand. Modern bulk carriers are over 300 meters long, carry between 200,000 and 300,000 tons, and use cranes and conveyor systems for rapid loading.

What are the different loading methods used on bulk carriers and why are they important?

-Homogeneous loading evenly distributes cargo across all holds, commonly used for grain or coal. High-density cargo like iron ore may use alternate hold or block hold loading methods. Proper loading ensures vessel stability during the voyage.

Why must weather conditions be monitored during grain loading?

-Rain can damage the grain, so loading must be paused if it rains. Hatches are closed and loading resumes only when conditions are safe, with hatch sealing tape applied to prevent water entry.

How do bulk carriers unload cargo, and what equipment is typically used?

-Bulk carriers unload cargo using onboard cranes or port-provided gantry cranes. For grain, clamshell buckets scoop material into hoppers, which then transfer it via conveyor systems. A bulldozer may be used to push remaining cargo toward the center for easier collection.

What are the key structural components of a bulk carrier?

-The superstructure is located at the aft and houses the bridge, crew accommodations, and operational rooms. Cargo holds are separated by corrugated transverse bulkheads and reinforced with longitudinal stiffeners. The engine room contains the main engine, diesel generators, steering gear, and tanks for water, fuel, and lubricants.

What safety improvements have been made to bulk carriers since the 1990s?

-After catastrophic failures due to corroded bulkheads and non-watertight hatches, stricter regulations were introduced by the IMO in 1997, improving bulkhead strength, inspection procedures, and overall ship safety, preventing flooding and structural failures.

How does a bulk carrier contribute to global trade?

-Bulk carriers transport raw materials such as grain from exporting countries to importing nations, supporting food production, processing into flour, cooking oil, and animal feed, and facilitating international distribution of these products.

What is the typical crew size on a modern bulk carrier, and what are their responsibilities?

-A modern bulk carrier typically operates with 20 to 30 crew members, responsible for navigation, operating machinery, loading/unloading cargo, maintenance, and ensuring the ship's overall safety and efficiency.

Why is constant maintenance and inspection critical for bulk carriers?

-Regular inspections and timely maintenance prevent corrosion, structural weaknesses, and potential flooding, which could lead to catastrophic failures, oil spills, or sinking, ensuring the vessel remains safe and operational.

How are residuals cleaned from the cargo hold after unloading?

-After unloading, holds are washed with fresh water, directing wash water to slop tanks. Any remaining residue in bilge wells is manually cleaned by workers, and air blowers are used to dry the hold, maintaining hygiene and preventing contamination.

What is the purpose of the specialized equipment like the winch-only area and clam shell gangway on bulk carriers?

-The winch-only area allows helicopters to lower supplies or personnel using a winching system, while the clamshell gangway facilitates safe boarding and disembarkation of workers during cargo operations.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

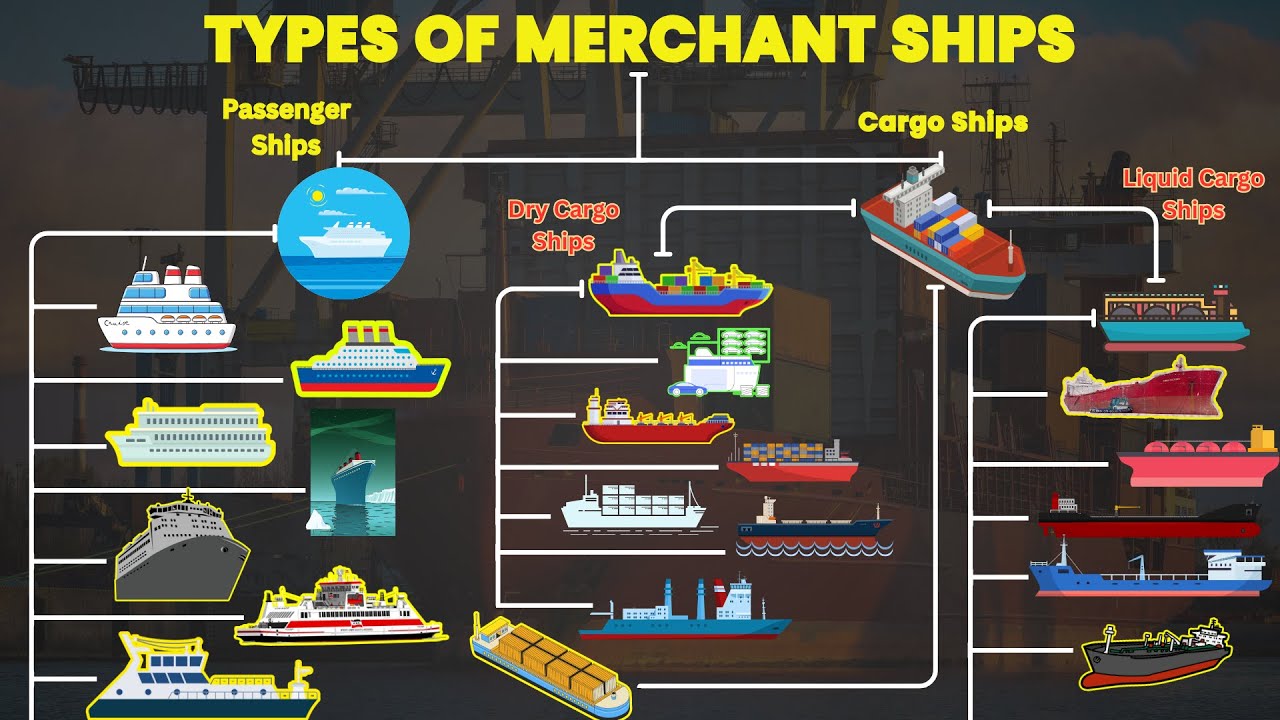

Different Types and Sub-Types of Merchant Ships

What Are These Cargo Ships Carrying? | Chief MAKOi Seaman Vlog

Iron and Steel

MARITIME ENGLISH - TYPES OF VESSELS - PART 1

Cement Raw Materials Grinding Process (Raw Mill System) _ English Version

Multi-Purpose Heavy Lift and General Cargo - Introduction to upcoming lectures

5.0 / 5 (0 votes)