Extrude beams from plastic waste #preciousplastic

Summary

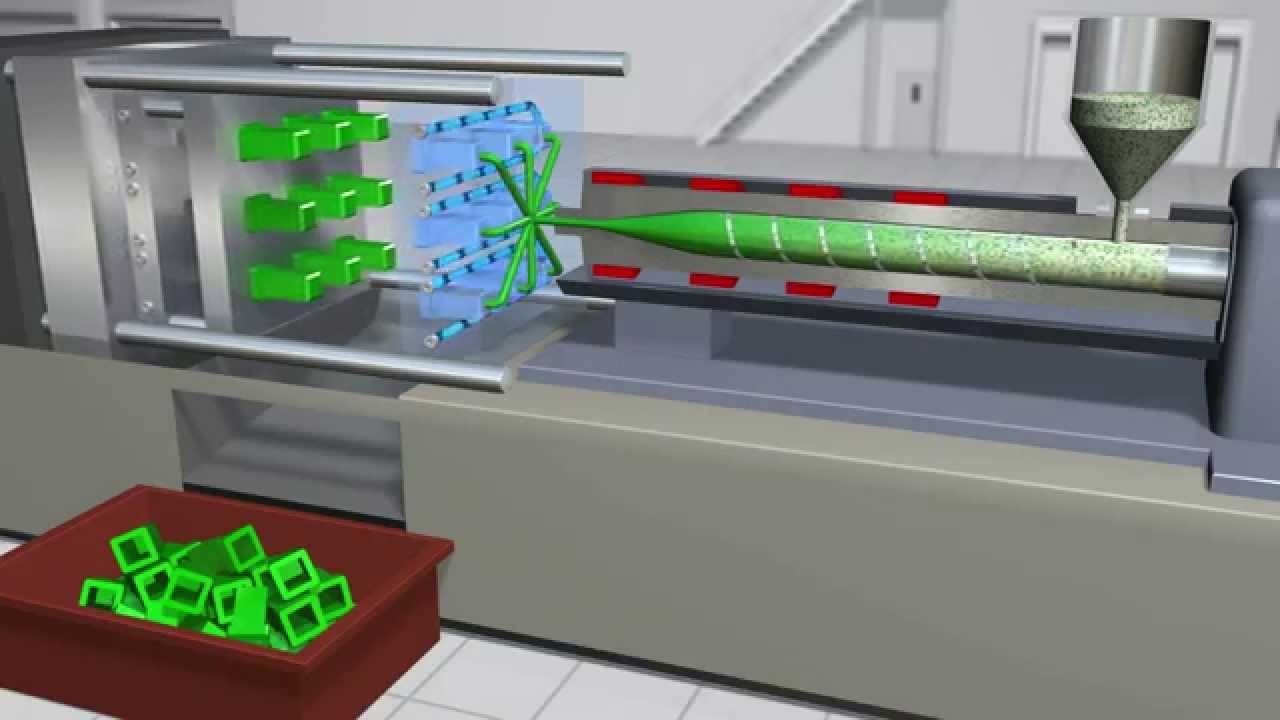

TLDRIn this video, the process of creating beams from recycled plastic using an upgraded extrusion machine is showcased. The tutorial covers mold selection, plastic extrusion, and cooling techniques to form durable, flexible beams. Various customization options like adjusting texture, color gradients, and shapes are explored. Additionally, the video discusses machine upgrades, including a more powerful motor and reinforced components for better pressure control. The possibilities for creating everything from large construction pieces to smaller furniture are highlighted, with an emphasis on the creative potential of this innovative recycling technique.

Takeaways

- 😀 The video demonstrates how to make beams from recycled plastic using an extrusion machine.

- 😀 The technique is ideal for recycling bulk plastic, with a focus on creating large amounts of extruded material.

- 😀 The mold can be made from basic metal tubes and can be customized into different shapes like round, square, or flat.

- 😀 Polypropylene is the primary material used for extrusion, and color changes can be introduced to create gradient effects.

- 😀 Cooling the extruded beams in water helps to relieve internal pressure and solidify the material.

- 😀 The extruded beams are flexible yet sturdy, making them suitable for various applications, such as furniture or construction.

- 😀 Playing with textures and colors is a key part of the technique, allowing for customization of the final product.

- 😀 You can alter the beam's texture by using a wooden block inside the mold to introduce friction and smooth the surface.

- 😀 The technique also allows for bending and reshaping the material after extrusion by reheating it.

- 😀 The extrusion machine requires an upgrade to handle the high pressure from extruding larger beams, including a stronger motor and reinforced barrel holder.

- 😀 The video encourages experimentation with different beam shapes, colors, and applications, showcasing the versatility of the technique.

Q & A

What is the main goal of this video?

-The main goal of the video is to show how to make plastic beams using an extrusion machine, demonstrating the process of recycling plastic into usable building material.

Why is the extrusion technique beneficial for recycling plastic?

-The extrusion technique is beneficial because it allows for the efficient recycling of plastic in bulk, turning shredded plastic into strong, usable beams for construction or other applications.

What material is primarily used for making the beams?

-Polypropylene is the primary material used for making the beams, although polyethylene and polystyrene are also experimented with.

What kind of mold is used to shape the plastic into beams?

-A basic metal tube is used as a mold. The tube can be round, square, or flat depending on the desired shape of the beam.

How does the extrusion process work?

-In the extrusion process, shredded plastic is fed into the extrusion machine, which heats and forces it through a mold to form the beam. The material is then cooled in water to maintain its shape and structure.

Why is it important to cool the extruded plastic in water?

-Cooling the extruded plastic in water is crucial because it helps solidify the material, ensuring that the plastic does not retain excessive internal pressure and holds its shape.

What options do you have to manipulate the texture and appearance of the beams?

-You can control the texture and appearance of the beams by adding wooden blocks inside the mold, adjusting the speed of extrusion, or using conventional tooling like sanding to smooth the surface. You can also play with colors and gradients.

What is the effect of using different materials like polystyrene?

-Polystyrene is harder and less flexible than polypropylene, but it doesn’t bend as easily. It also shrinks less during the extrusion process, which can make it harder to remove from the mold.

What is the significance of the extrusion screw upgrade?

-The extrusion screw upgrade is significant because it allows the machine to generate more pressure, which is necessary for extruding larger beams. The screw has smaller gaps towards the end, which compresses the material to build up pressure.

What should be done to reinforce the extrusion machine for larger beams?

-To reinforce the extrusion machine for larger beams, it is recommended to upgrade the motor, reinforce the barrel holder, and ensure the machine's frame is strong enough to withstand the increased pressure.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Plastic Processing Overview

Cara Menanam Kangkung Dalam Botol Tidak Perlu Penyiraman Lagi Sampai Panen | Urban Farming

Putting plastic rubbish into new roads | ITV News

How Waste Plastic is Converted into Fuel | Plastic Pyrolysis | Karthi Explains

KEREN! BEGINI PROSES MODERN DAUR ULANG SAMPAH PLASTIK MENJADI PRODUK JADI DI NEGARA MAJU

como se hacen las botellas de plastico

5.0 / 5 (0 votes)