BMCS - V0403 plastic interaction

Summary

TLDRThe video explores irreversible changes in material structures, focusing on plasticity and bond slip models in the context of material behavior under stress. It introduces mathematical tools for describing damage and plasticity, particularly through isotropic and kinematic hardening. Using a simple one-dimensional interface model, the video demonstrates how these concepts influence stress and slip displacement during loading and unloading cycles. The interactive model and simulation results are used to visually explain the effects of parameters like bond stiffness, yield stress, and hardening, offering insights into dissipative processes in materials and laying the groundwork for further mathematical modeling.

Takeaways

- 😀 The script discusses irreversible changes in material structure, categorized into damage and plasticity.

- 😀 Mathematical tools are needed to describe irreversible changes in materials, especially in plasticity and damage.

- 😀 The constant bond slip law from previous discussions assumed a plastic process, focusing on stick-slip behavior under constant stress.

- 😀 The material undergoes irreversible slip during loading, which remains even when unloaded, representing a permanent change in material structure.

- 😀 The script introduces the concept of plasticity theory, using a simple one-dimensional interface model to explain inelastic behavior.

- 😀 Isotropic hardening and kinematic hardening are discussed, both of which affect the plastic behavior of the material.

- 😀 The presentation uses an interactive bond slip model to visualize the effect of hardening parameters on material behavior.

- 😀 Isotropic hardening enlarges the elastic domain, shifting the yield stress limit and increasing the material's elastic range.

- 😀 Kinematic hardening shifts the midpoint of the elastic domain, affecting how the material behaves under cyclic loading.

- 😀 The role of the parameters (isotropic hardening modulus, kinematic hardening modulus) is to control how the material yields and reloads, as well as to predict the elastic domain's behavior during unloading.

- 😀 The script highlights that the bond slip model can be controlled interactively or through a scripting interface, which allows for precise simulation of material behavior under varying conditions.

Q & A

What are the two main categories of irreversible changes in material structure discussed in the transcript?

-The two main categories of irreversible changes in material structure discussed are damage and plasticity.

What is the role of plasticity theory in describing irreversible material changes?

-Plasticity theory helps to describe irreversible changes in materials by modeling the inelastic behavior and the permanent deformation that occurs under stress, specifically through mechanisms such as isotropic and kinematic hardening.

What is the significance of the bond slip model introduced in the transcript?

-The bond slip model is used to demonstrate the effects of plasticity on materials, including how stresses and displacements evolve during loading and unloading cycles. It serves as an intuitive framework to explore the behavior of materials under stress, incorporating concepts like isotropic and kinematic hardening.

What is the difference between isotropic and kinematic hardening in plasticity theory?

-Isotropic hardening increases the size of the elastic domain by shifting the yield stress, while kinematic hardening causes the yield surface to move without changing its size, allowing the material to undergo plastic deformation in a more controlled manner during cyclic loading.

How does isotropic hardening affect the elastic domain of a material?

-Isotropic hardening shifts the midpoint of the elastic domain, which alters the yield stress without affecting the overall size of the elastic domain. This shift causes the material to yield at a higher stress level compared to its initial state.

What happens to the material's behavior during unloading when isotropic hardening is applied?

-During unloading with isotropic hardening, the material shows a stress response that indicates an enlarged elastic domain, as the yield stress increases. This results in a larger distance between the boundaries of the elastic domain, making the material less likely to yield during future loading cycles.

What is the impact of kinematic hardening on the material’s stress-strain response?

-Kinematic hardening increases the size of the elastic domain and alters the material's stress-strain response by shifting the yield surface in response to cyclic loading. This allows the material to undergo plastic deformation more easily without significant changes to the elastic range.

How do the parameters 'k' and 'gamma' influence the bond slip model?

-'k' (the isotropic hardening modulus) affects the size of the elastic domain, while 'gamma' (the kinematic hardening modulus) influences the movement of the yield surface. Both parameters control how the material responds during loading and unloading cycles.

Why does the model show a spiral pattern during loading and unloading?

-The spiral pattern observed during loading and unloading indicates a cyclic change in the material's stress and displacement. This pattern reflects the progressive changes in the material's state due to the interaction of loading, unloading, and the hardening mechanisms.

How can the bond slip model be controlled outside the interactive interface?

-The bond slip model can also be controlled through a scripting interface by defining target displacements and running simulations using specific data entries and commands, offering more flexibility for advanced users to explore various scenarios.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Understanding plasticity theory (for Mises UMAT)

Constitutive Models— Lesson 1

Kuliah 2 IBK Sifat Mekanis Bahan part 1

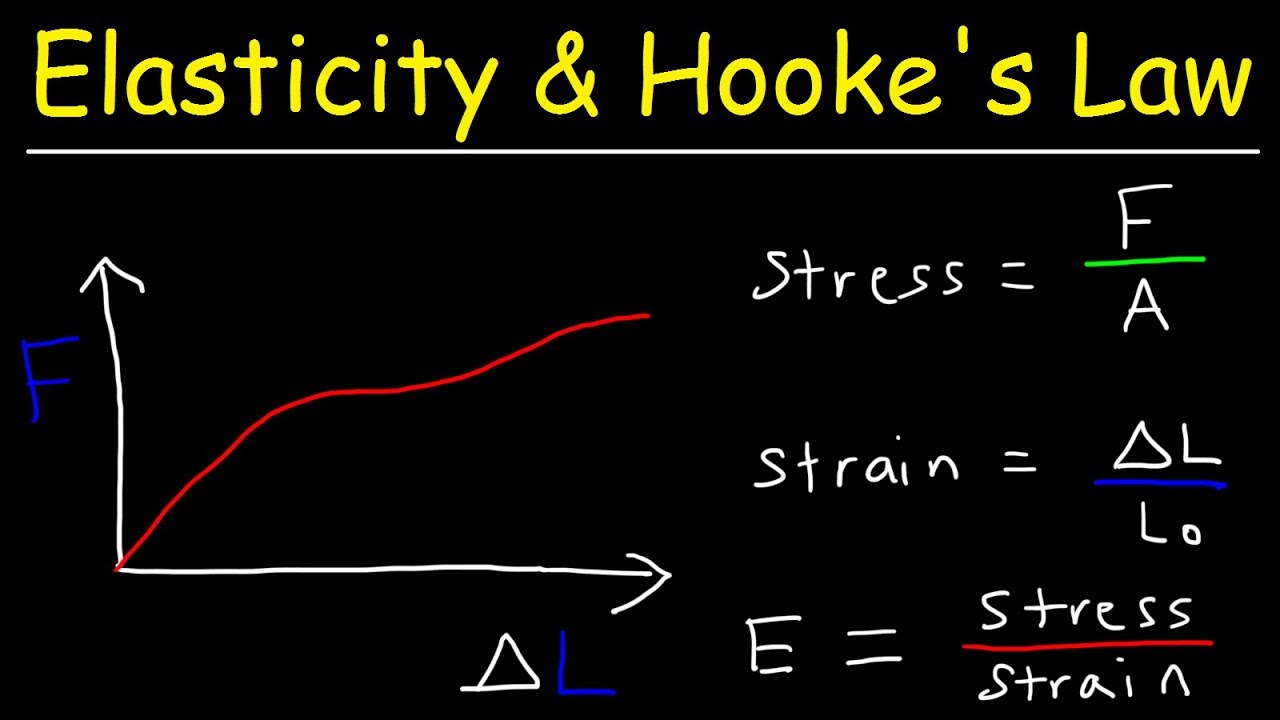

Elasticity & Hooke's Law - Intro to Young's Modulus, Stress & Strain, Elastic & Proportional Limit

Stress and Strain | Stress strain curve of mild steel | Mechanical Properties of Solids |

Mechanics of Solids Interview Questions

5.0 / 5 (0 votes)