QUALITY FUNCTION DEPLOYMENT QFD

Summary

TLDRIn this video, the concept of Quality Function Deployment (QFD) is introduced, focusing on its role in new product development. QFD is a structured approach to transforming customer needs into specific product requirements, ensuring alignment with customer expectations. The process includes key steps such as gathering customer desires, defining technical specifications, assessing relationships, and setting measurable goals. The method enhances customer orientation, streamlines product development, and fosters improved teamwork. By translating customer feedback into actionable technical objectives, QFD improves efficiency, reduces costs, and supports better communication in the product development process.

Takeaways

- 😀 QFD (Quality Function Deployment) is a structured approach to defining customer needs and translating them into specific product development plans.

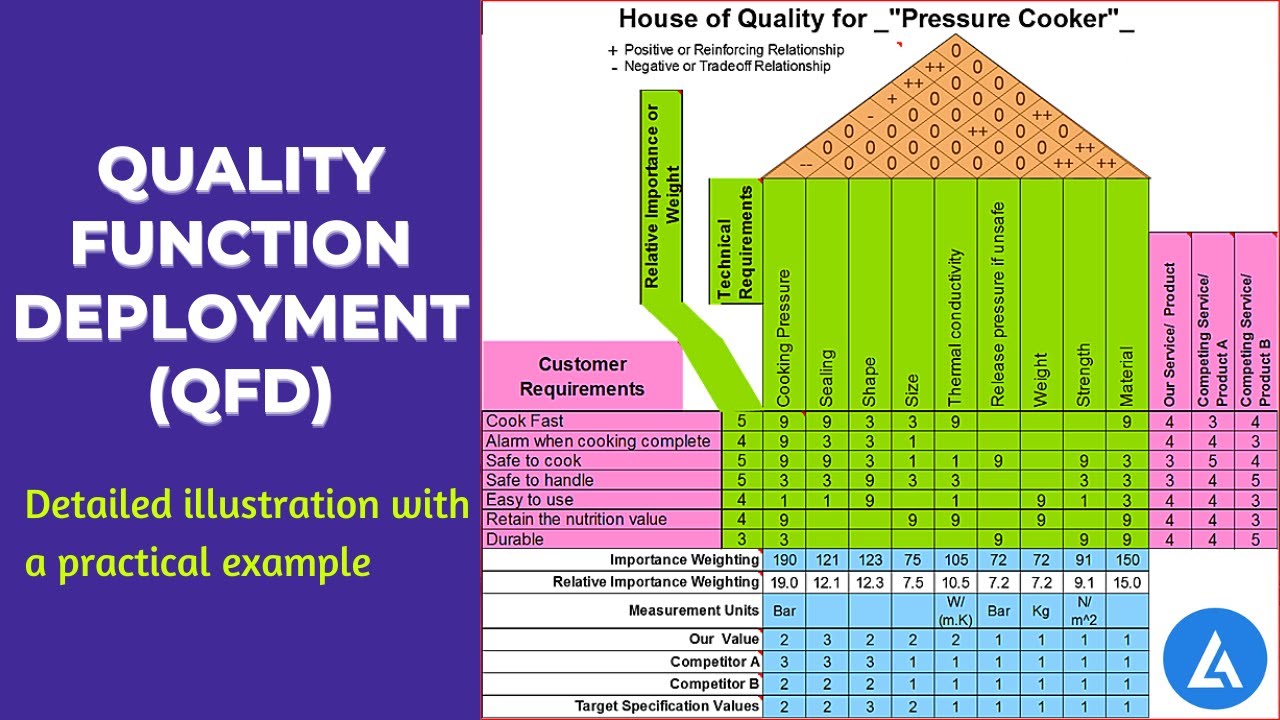

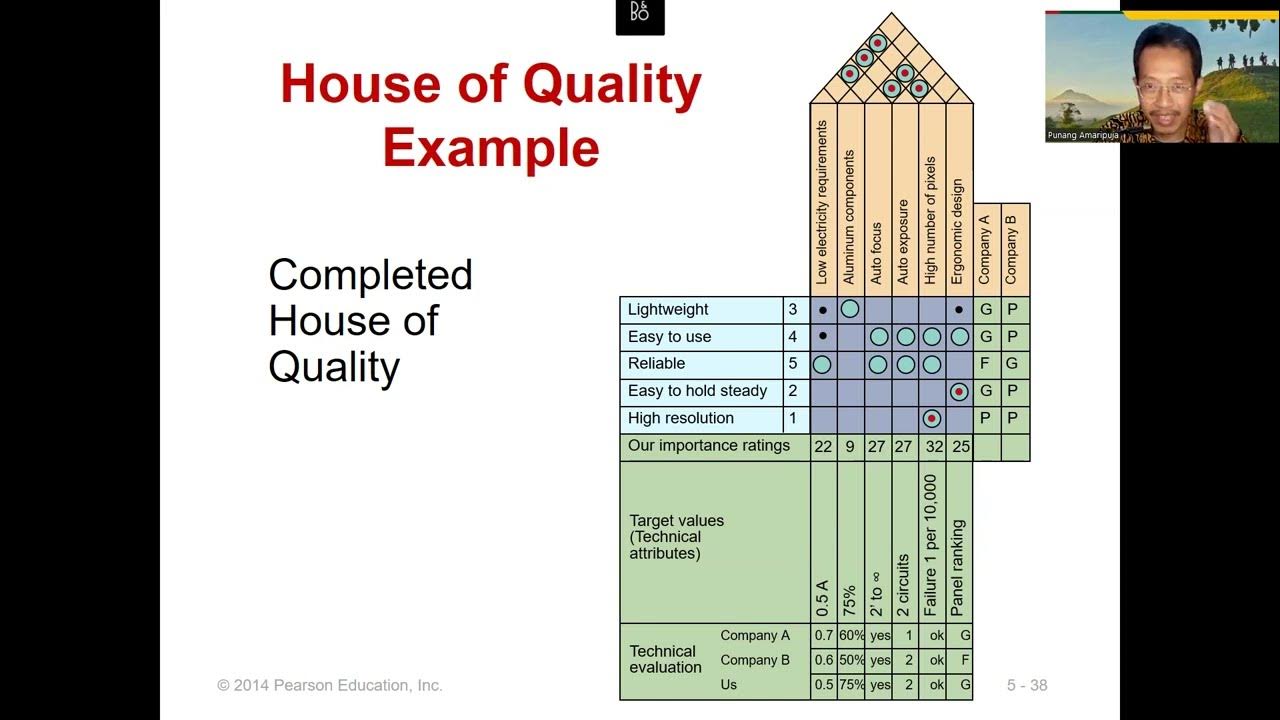

- 😀 The House of Quality (HOQ) is a matrix tool used in QFD to align customer requirements with engineering characteristics and technical specifications.

- 😀 The first step of QFD is gathering the 'Voice of the Customer' to understand their desires and needs, typically through customer service interactions.

- 😀 In the second step, 'Planning Metrics,' customer needs are analyzed quantitatively, prioritizing them based on their importance and market competitiveness.

- 😀 The third step, 'Technical Response,' translates customer needs into actionable technical specifications that the production team can work with.

- 😀 'Relationship Metrics' in step four assess the correlation between customer needs and technical responses to prioritize actions that most impact customer satisfaction.

- 😀 In the fifth step, 'Technical Correlation,' the interrelationship between different technical responses is analyzed to identify conflicts or synergies.

- 😀 The sixth step, 'Technical Metrics,' sets measurable technical performance targets to ensure the product meets customer expectations and industry standards.

- 😀 QFD provides three key benefits: enhanced customer orientation, effective product development, and improved communication and teamwork.

- 😀 QFD aligns product development closely with customer expectations, improving customer satisfaction and market competitiveness.

- 😀 By streamlining product development and minimizing design changes, QFD helps companies reduce development costs and improve efficiency.

Q & A

What is Quality Function Deployment (QFD)?

-Quality Function Deployment (QFD) is a structured approach used in new product development to translate customer needs into specific product plans. It helps ensure that products meet customer expectations by aligning the design and production process with customer requirements.

How does QFD contribute to new product development?

-QFD contributes to new product development by focusing on customer requirements, product design, and a thorough evaluation process. It helps improve engineering knowledge, productivity, product quality, and reduces costs by translating customer needs into actionable product specifications.

What are the six steps involved in the QFD process?

-The six steps involved in the QFD process are: 1) Voice of the Customer (V.O.C.), 2) Planning Metrics, 3) Technical Response (The House), 4) Relationship Metrics, 5) Technical Correlation (The Roof), and 6) Technical Metrics.

What is the purpose of the Voice of the Customer (V.O.C.) step?

-The purpose of the Voice of the Customer (V.O.C.) step is to understand and gather customer needs and desires. This foundational step ensures that the product development process is focused on what the customers truly want.

How are customer needs quantified in the QFD process?

-Customer needs are quantified in the QFD process through the Planning Metrics step. This involves analyzing the importance of each customer need and comparing the product's specifications to competitors, helping to prioritize areas for improvement.

What is the role of the Technical Response (The House) in QFD?

-The Technical Response (The House) is a step where customer needs are translated into technical specifications. This ensures that production teams understand customer requirements in measurable, actionable terms, such as material specifications and quality standards.

What are Relationship Metrics in the context of QFD?

-Relationship Metrics in QFD evaluate the strength of the correlation between customer needs and technical responses. This step helps determine which technical features will have the greatest impact on satisfying customer expectations.

What does the Technical Correlation (The Roof) step assess in QFD?

-The Technical Correlation (The Roof) step assesses the relationship between different technical responses. It identifies any conflicts or synergies between technical requirements, such as how increasing durability might impact manufacturing ease, helping to make informed trade-offs.

How are Technical Metrics used in the QFD process?

-Technical Metrics involve setting measurable performance targets and benchmarks to ensure the product meets required standards. This helps guide the production process and ensures the product remains competitive in the market.

What are the main benefits of implementing QFD in product development?

-The main benefits of QFD are: enhanced customer orientation by aligning products with customer expectations, effective product development by reducing costs and improving efficiency, and improved communication and teamwork by fostering collaboration across departments.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

QFD (Quality Function Deployment): With Practical Example (PART-1)

CBME 1 | Lesson 2 | Part 1/3

House of Quality (QFD) || Dr Punang Amaripuja Serial Operasi dan Teknologi - MOT 05B

Penetapan Produk Unggul dan Manajemen Inovasi

Design Selection (Pugh Matrix, TOPSIS, SDI Matrix) using Triptych

MO Chapter 6 Product Design

5.0 / 5 (0 votes)