Penjadwalan Produksi (PPC week 8 - sesi 1)

Summary

TLDRThe transcript focuses on short-term production planning and scheduling, specifically highlighting the need for efficient management of limited resources like machines and operators. It discusses factors that influence production, such as machine limitations and the importance of scheduling in relation to available resources. The material emphasizes performance criteria, comparing scheduling methods based on job completion time, machine idle time, and customer service expectations. Key concepts like tardiness, job sequencing, and machine scheduling are explained, aiming to guide decision-making processes in a dynamic production environment.

Takeaways

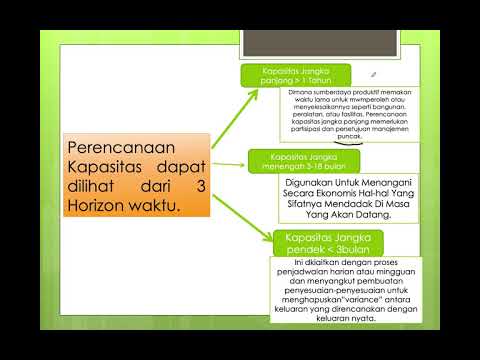

- 😀 Short-term production planning focuses on quick decision-making and scheduling, typically within one week to six months.

- 😀 Production activities are influenced by factors like machine availability, material arrival, and operator limitations.

- 😀 Scheduling is essential due to resource constraints, such as machine and operator availability, which requires careful prioritization.

- 😀 Static scheduling means the jobs are scheduled before execution, while dynamic scheduling allows for adjustments during execution based on new jobs.

- 😀 Performance criteria are vital for evaluating the effectiveness of schedules. These include minimizing average wait times, reducing idle machine times, and meeting customer promises.

- 😀 Scheduling methods do not always perform equally across all performance criteria, so it's crucial to understand which criteria are most important.

- 😀 Performance metrics like completion time, tardiness, and processing time help measure the quality of a schedule and determine delays.

- 😀 Scheduling decisions are affected by factors like machine setup, job arrival order, and processing time, which can impact system performance.

- 😀 In production environments, the method of scheduling needs to align with the company's goals, customer expectations, and the available resources.

- 😀 Different scheduling algorithms, like Shortest Processing Time (SPT) or Earliest Deadline First (EDF), optimize specific performance goals, such as minimizing tardiness or improving machine utilization.

Q & A

What is the main difference between short-term and medium-term production planning?

-Short-term production planning typically involves decisions made on a daily or weekly basis, whereas medium-term planning spans a few months to years. Short-term planning focuses on immediate production needs, while medium-term planning addresses more extended resource allocation.

Why is scheduling important in production planning?

-Scheduling is crucial in production planning because it helps allocate limited resources, such as machines, operators, and materials, efficiently. Without scheduling, production could be chaotic, leading to underutilized or overburdened resources.

What are some key factors that influence production scheduling?

-Key factors influencing production scheduling include resource availability (e.g., machines, operators), job priorities, job durations, and the type of scheduling system (static vs. dynamic). These factors determine how and when tasks are assigned to machines or operators.

What is the difference between static and dynamic scheduling?

-Static scheduling assumes that all jobs are known in advance, allowing for a fixed schedule to be created. In contrast, dynamic scheduling responds to new jobs arriving during production, requiring adjustments to the schedule as tasks change.

What does the term 'performance criteria' refer to in production scheduling?

-Performance criteria in production scheduling refer to measurable factors used to evaluate the effectiveness of a schedule. These include metrics such as flow time (the total time a job spends in the system), tardiness (delay in job completion), and machine idle time.

How does flow time impact production scheduling?

-Flow time is the total duration a job stays in the system, from start to finish. A schedule that minimizes flow time helps increase overall production efficiency by reducing the time jobs spend waiting in the system.

Why is minimizing tardiness important in production scheduling?

-Minimizing tardiness ensures that jobs are completed on time, meeting customer expectations and contractual deadlines. Late deliveries can result in penalties, customer dissatisfaction, and lost business.

What is the Shortest Processing Time (SPT) rule, and when is it used?

-The Shortest Processing Time (SPT) rule prioritizes jobs with the shortest processing times first. This scheduling method is typically used when the goal is to minimize flow time and improve overall system efficiency.

What role does the Earliest Due Date (EDD) rule play in scheduling?

-The Earliest Due Date (EDD) rule prioritizes jobs that are closest to their due date. It is used to minimize tardiness and ensure that jobs are completed on time, reducing the chances of missing deadlines.

What are some challenges when selecting a scheduling method?

-Selecting a scheduling method can be challenging because different methods excel at different objectives. For instance, some methods minimize flow time, while others prioritize reducing tardiness. The right method depends on the specific goals of the production system, such as customer requirements or machine utilization.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

What is the difference between production planning and scheduling?

MPO KAPASITAS PABRIK

Introduction to Aggregate Planning (Meaning, Concept, Objectives, Steps, Benefits, Inputs & Outputs)

KELOMPOK 5 SPS2 ASPEK MANAJEMEN DAN SDM

GESTÃO DE PROJETOS - AGENDA 06

Seri 3 [1] Perencanaan Tata Guna Lahan Berkelanjutan

5.0 / 5 (0 votes)