Telecurso 2000 Processos de Fabricação 13 O gás veio para fundir

Summary

TLDRThis telecourse introduces oxy-fuel welding, explaining its history, equipment, and techniques. The script covers the key components of the welding setup, such as cylinders, pressure regulators, and torches. It highlights the types of gases used, like acetylene and oxygen, and their importance in creating various flame types for different applications. The course demonstrates two main welding techniques and discusses safety precautions when working with high temperatures and flammable gases. Practical tips for maintaining and handling equipment are provided, along with a focus on ensuring safety and effective welds.

Takeaways

- 😀 Welding is one of the main methods used to permanently join metal pieces.

- 😀 Oxy-fuel welding, also known as oxyacetylene welding, is a key process introduced after World War I.

- 😀 Oxy-fuel welding requires specific equipment, including cylinders for gases, pressure regulators, hoses, and a torch.

- 😀 There are two common types of torches: low-pressure injectors and mixer torches, each suited for different tasks.

- 😀 Safety is critical when using oxy-fuel welding equipment due to high temperatures and highly flammable gases.

- 😀 The primary gases used are oxygen and acetylene, which together produce a high-temperature flame for welding.

- 😀 Different flame types, such as reducing, neutral, and oxidizing flames, are used depending on the material being welded.

- 😀 The welding process involves melting the base metal and adding filler metal to form a weld joint.

- 😀 There are two main techniques in oxy-fuel welding: left-handed and right-handed welding, with the latter offering better control and precision.

- 😀 Common issues in oxy-fuel welding include improper flame regulation, which can lead to dangerous backfire or flashback incidents.

- 😀 Proper equipment handling and maintenance, including regular checks for leaks and using protective gear, are essential for safe operation.

Q & A

What is oxy-gas welding, and when did it become widely used?

-Oxy-gas welding, also known as oxyacetylene welding, is a process that uses a mixture of gases, primarily oxygen and acetylene, to create a high-temperature flame for welding metal. It became widely used after World War I, in the 20th century.

What equipment is required for oxy-gas welding?

-The basic equipment for oxy-gas welding includes two gas cylinders (one for oxygen, one for acetylene), pressure regulators, hoses, and a torch (or 'maçarico'). The torch has several components, including a body injector, a gas mixer, a lance, and a nozzle.

What is the role of the pressure regulators in oxy-gas welding?

-The pressure regulators control the gas pressure coming out of the cylinders and ensure it is at the proper level for the welding process. There are two types of regulators: single-stage and two-stage, with the latter providing more consistent pressure.

What are the different types of torches used in oxy-gas welding?

-There are two common types of torches used in oxy-gas welding: the low-pressure injector torch and the mixer torch. The injector torch has a constant gas mixture, while the mixer torch allows for control over the proportion of gases used.

Why is safety important in oxy-gas welding, and what equipment is necessary for protection?

-Safety is crucial in oxy-gas welding due to the extremely high temperatures of the flame and the flammability of the gases. Essential protective equipment includes safety glasses, appropriate clothing, and a welding helmet to shield the eyes from intense light and heat.

What are the types of flames used in oxy-gas welding, and what are their applications?

-There are three types of flames used in oxy-gas welding: reducing flame (with more acetylene than oxygen, used for welding ferrous metals and alloys), neutral flame (with equal parts of acetylene and oxygen, used for most metals), and oxidizing flame (with more oxygen than acetylene, used for welding metals like galvanized steel).

What is the difference between the base metal and filler metal in welding?

-The base metal refers to the materials being joined or welded, while the filler metal (or 'metal de adição') is the material, usually in the form of a rod or wire, that is melted and added to create the weld pool.

How do fluxes assist in oxy-gas welding?

-Fluxes are used to prevent oxidation during the welding process, especially when welding non-ferrous metals like aluminum. They can come in the form of powders or pastes and help clean the metal surfaces for better bonding.

What are the two common welding techniques used in oxy-gas welding?

-The two common techniques in oxy-gas welding are the 'leftward welding technique,' which provides better visibility of the weld pool, and the 'rightward welding technique,' which is used for thicker materials and allows better control over the fusion zone.

What safety precautions should be taken when using oxy-gas welding equipment?

-Key safety precautions include carefully regulating gas pressures, using special trolleys for transporting cylinders, storing equipment in well-ventilated areas, ensuring the valves and hoses are intact, and wearing proper protective gear. It is also important to handle hot metals with tongs to avoid burns.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

History of Welding

Telecurso 2000 Processos de Fabricação 14 O arco elétrico entra em ação

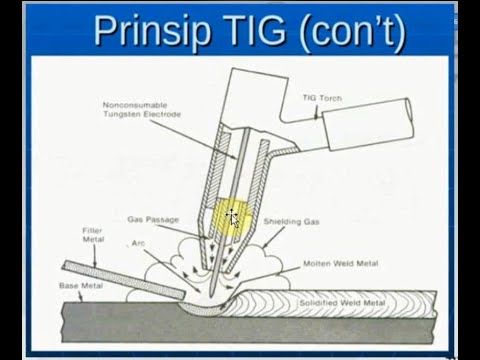

Prinsip Kerja dan Komponen Las TIG (Tungsten Inert Gas)

MENGATUR TEKANAN KERJA GAS PADA INSTALASI LAS OXY ACETYLENE WELDING (OAW) ATAU LAS KARBIT

Processos de Fabricacao - Soldagem por resistência

ITI Welder Trade Theory NIMI MCQ Series 1 | NIMI Welder MCQ Question Bank Bharat Skill By Sumit Sir

5.0 / 5 (0 votes)