Copper and Nickel Plating | Elektroplating tembaga dan Nikel Lengkap

Summary

TLDRThe video provides an insightful look into the process of electroplating in a mechanical engineering lab. The presenter walks through the various stages of electroplating, including surface cleaning, pickling, activating, and applying a nickel strike layer. Detailed explanations of the chemicals used, such as KOH and HCl, and the specific techniques for achieving a smooth, durable metal coating are provided. The video highlights the hands-on experience in the lab, with a focus on ensuring uniform coating, monitoring temperatures, and measuring the thickness of the metal layers.

Takeaways

- 😀 The electroplating laboratory is located in the outdoor section of the Mechanical Engineering Education Department, and it is equipped for research activities, particularly in electroplating and manufacturing.

- 😀 Electroplating involves two main processes: the preparation phase, which includes cleaning and etching, and the actual electroplating phase where the metal is deposited onto a surface.

- 😀 The first step in electroplating is cleaning the surface of the workpiece to remove oils, dirt, and other contaminants. This is done using a soap-like solution (KOH) and is followed by rinsing to prevent contamination between different chemical baths.

- 😀 Pickling is the next step where rust or corrosion is removed using an HCl solution, which is adjusted based on the material of the workpiece.

- 😀 After pickling, the workpiece is activated to ensure a consistent pH level, preparing it for the nickel strike bath. This process ensures the metal surface is properly prepared for plating.

- 😀 Nickel strike is a thin layer of nickel applied as a base coat to stainless steel workpieces. This step is not required for carbon steel workpieces.

- 😀 The nickel strike process is followed by electroplating, which involves the transfer of metal ions from the plating bath onto the workpiece, building up a thin, uniform coating.

- 😀 The electroplating process is controlled by immersion time, with the workpiece being submerged for a specific duration and then flipped to ensure even coverage.

- 😀 The plating bath contains metal salts that supply ions for the plating process, and it’s essential to maintain the temperature of the bath for optimal results. For stainless steel, the bath temperature is kept between 40-60°C.

- 😀 The thickness of the electroplated layer is monitored throughout the process, and the final step involves rinsing and drying the workpieces to prevent water contamination before weighing them for final analysis.

Q & A

What is the primary function of the outdoor materials laboratory in this university?

-The outdoor materials laboratory is dedicated to research and experimentation in electroplating and manufacturing. It provides facilities for students' research projects, particularly in metal coating processes like electroplating.

What are the two types of electroplating processes mentioned in the video?

-The two types of electroplating processes mentioned are free electroplating and electroplating itself.

What is the purpose of the hot big racing velg in the electroplating process?

-The hot big racing velg is used for the degreasing process, which cleans off oils, coolants, and other organic contaminants from the workpieces after manufacturing.

What is rinsing in electroplating, and why is it important?

-Rinsing is the process of washing the workpieces with clean water to remove any residual chemicals or solutions, ensuring that no contamination occurs between different stages of the electroplating process.

How does the pickling process help in the electroplating process?

-Pickling removes oxidation or corrosion on the metal surface using a hydrochloric acid solution, preparing the metal for the electroplating process by ensuring a clean and smooth surface.

What is the purpose of the activation process in electroplating?

-The activation process is designed to equalize the pH levels of the workpiece, ensuring proper bonding of the plating material during electroplating.

What role does nickel play in electroplating?

-Nickel is used as a base layer in the electroplating process, particularly for stainless steel workpieces, to provide a smooth and corrosion-resistant surface.

Why is it necessary to reverse the workpieces during the electroplating process?

-Reversing the workpieces every minute ensures that both sides of the workpiece receive an even coating of the plating material, allowing for uniform thickness and quality.

What is the significance of using a hot gun in the final electroplating steps?

-The hot gun is used to dry the electroplated workpieces after the plating process is complete, ensuring that no water remains, which could affect the accuracy of the final measurements.

How is the thickness of the electroplated layer measured?

-The thickness of the electroplated layer is measured using a microbalance to weigh the workpiece before and after plating, and the change in weight is used to calculate the layer thickness.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

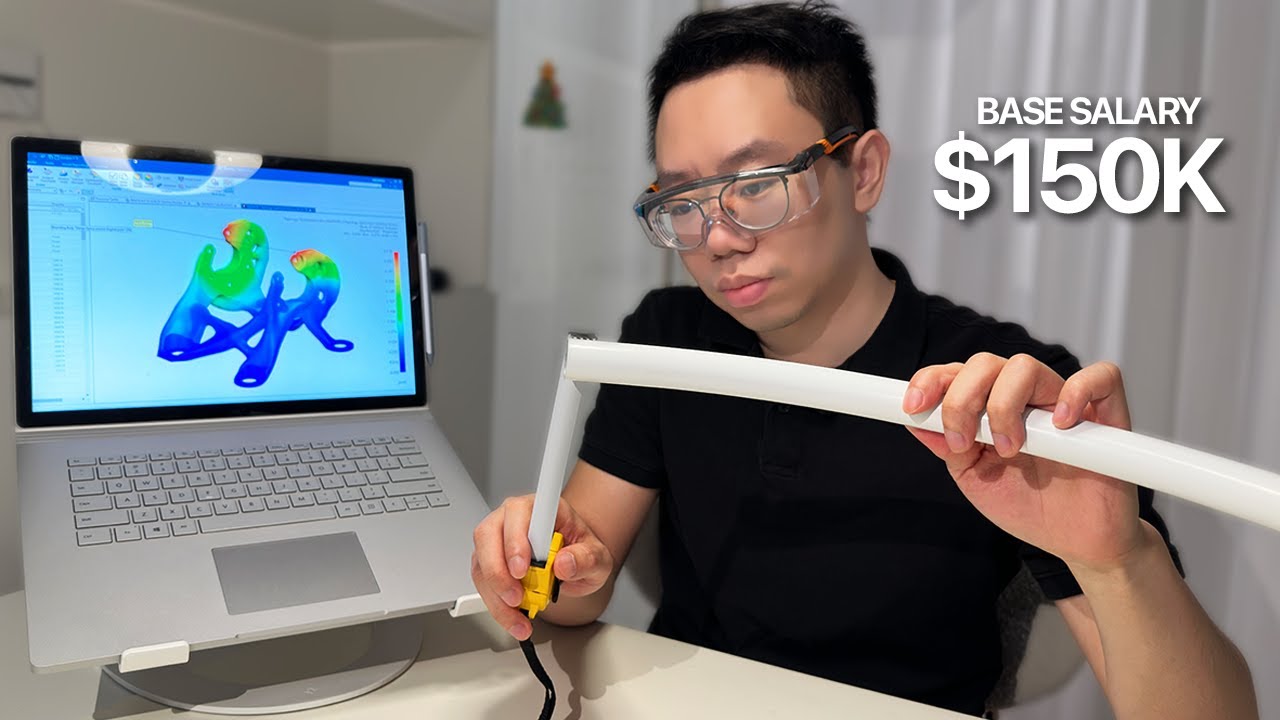

Pengalaman Jurusan Teknik Mesin di Dunia Kerja Subscribe Like Comment

3D Digestive System of Human Body | Gastrointestinal Tract Animation

What do I do as a Mechanical Engineer?

What is Mechanical Engineering?

How Mechanical Engineers Design Products

Vid9 Serial Elektrokimia Elektrolisis, Elektroplating atau Pelapisan Logam

5.0 / 5 (0 votes)