Air Pollution Control by Fabric Filtration

Summary

TLDRThis presentation explores fabric filtration methods for air pollution control, focusing on types of fabric filters, their design, and cleaning mechanisms. It covers common cleaning techniques like shaking, reverse air, and pulse jet, alongside operational modes such as intermittent, periodic, and continuous. The script delves into filter materials, their efficiency, and performance monitoring, highlighting challenges such as abrasion, blinding, and temperature damage. It also outlines field inspection processes to evaluate filter performance, including opacity monitoring and pressure drop analysis. The presentation emphasizes safety protocols, particularly regarding confined space entry during maintenance.

Takeaways

- 😀 Fabric filters are used to control air pollution by removing particles from contaminated gas streams.

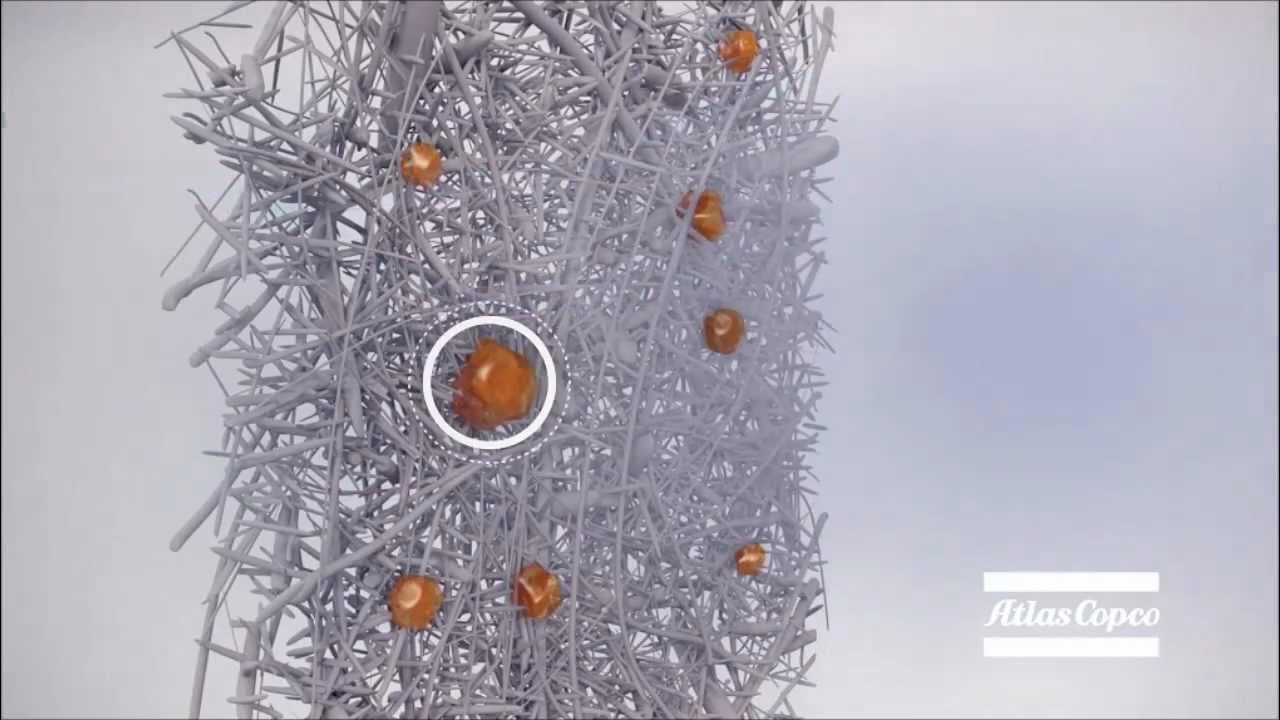

- 😀 Fabric filters are commonly in the form of cylindrical fabric bags, but can also be cartridges made of fabric, metal, or ceramic.

- 😀 The effectiveness of fabric filters depends on the cleaning method, with common types being shaking, reverse air, and reverse pulse (pulse jet) cleaning.

- 😀 Fabric filter systems operate in different modes: intermittent, periodic, and continuous, each suited for different operational processes.

- 😀 Shaker collectors clean the bags by gently shaking them, dislodging the dust cake to fall into the hopper for removal.

- 😀 Reverse air collectors use reverse airflow to clean the bags, dislodging the dust cake without fully collapsing the bags.

- 😀 Pulse jet collectors clean the bags using short-duration pulses of compressed air to remove dust without stopping the operation.

- 😀 Cartridge collectors are similar to pulse jet collectors, but use smaller, pleated filter elements to increase filtering area.

- 😀 High-efficiency particulate air (HEPA) filters are used for sub-micron particle removal and are typically changed when the pressure drop exceeds a certain limit.

- 😀 Monitoring fabric filter performance involves checking parameters like opacity, pressure drop, temperature, and bag integrity to ensure proper function and efficiency.

Q & A

What is the main purpose of the presentation?

-The purpose of the presentation is to provide a basic understanding of fabric filtration, methods used to control air pollution, and the control devices in this category.

What are fabric filters typically made of?

-Fabric filters are usually made of cylindrical fabric bags, though they may also be in the form of cartridges constructed from fabric, centered metal, or porous ceramic.

What are the three common types of fabric filter collectors?

-The three common types of fabric filter collectors are shaker collectors, reverse air collectors, and reverse pulse or pulse jet collectors.

How do intermittent fabric filter collectors operate?

-Intermittent fabric filter collectors are used in processes that operate intermittently, and they clean the filter material during the downtime between cycles.

What is the primary method used to clean fabric filters?

-The most common cleaning methods for fabric filters are shaking, reverse air, and reverse pulse (pulse jet).

How does a reverse pulse or pulse jet collector clean the filter bags?

-In a reverse pulse collector, compressed air pulses are directed at rows of bags to dislodge dust cake, which falls into the hopper, while other bags continue to filter the air.

What materials are commonly used in the construction of pulse jet filter media?

-Pulse jet filters typically use a heavyweight felted fiber material, chosen based on the characteristics of the particles and the gas stream.

How do high velocity air filters (HVAF) work?

-HVAF filters collect particulate matter by impacting the particles on a linear filter mat that is slowly unrolled and banded around a porous rotating drum or travels over a flat bed.

What is the role of opacity monitoring in evaluating fabric filter performance?

-Opacity monitoring helps detect changes in the visibility of the gas stream, which can indicate problems with the fabric filter, such as failed bags or leakage.

What safety considerations are associated with fabric filter systems?

-Safety considerations include confined space hazards and hot surfaces. Field personnel should never enter the inside of a fabric filter device without following OSHA's confined space entry protocols.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)