Sequential-Sampling Plans

Summary

TLDRThis video script covers the sequential sampling method in quality control, emphasizing how decisions to accept or reject lots are made based on sample data. It explains graphical and tabular methods for determining acceptance and rejection, explores the role of operating characteristic curves, and highlights key metrics like the acceptance number and average sample number. The script also discusses rectifying inspection to improve quality and includes formulas for calculating necessary values.

Takeaways

- 😀 Sequential sampling involves taking samples one at a time, with decisions about acceptance or rejection based on the number of defectives found during the process.

- 😀 In sequential sampling, decisions are often made using graphical methods where a plot of samples inspected vs. defectives is used to make acceptance or rejection decisions.

- 😀 The acceptance and rejection lines in a sequential sampling plan are defined by equations involving parameters like lot fraction defective (p) and probabilities (α and β).

- 😀 When the lot fraction defective is lower than the acceptance line, the lot is accepted; if it's above the rejection line, it is rejected; and if it’s between the two, further sampling is needed.

- 😀 Sequential sampling differs from fixed sampling plans as it continues sampling until a decision is made, allowing for more efficient inspection when defect rates are low.

- 😀 The operating characteristic (OC) curve is used to show the relationship between the lot fraction defective (p) and the probability of acceptance, helping visualize the performance of the sampling plan.

- 😀 Average Sample Number (ASN) is an important metric in sequential sampling that helps determine the expected number of samples taken during the inspection process.

- 😀 Rectifying inspection refers to a process where all defectives in a rejected lot are replaced with good items to improve the quality of the lot.

- 😀 The amount of sampling in sequential sampling is determined by the values of parameters like α, β, p₁, and p₂, which can be used to calculate the necessary sample size.

- 😀 The average total inspection effort can be calculated based on parameters like acceptance probabilities and lot fraction defective, providing insight into the overall cost-effectiveness of the sampling plan.

Q & A

What is the concept of sequential sampling in quality control?

-Sequential sampling is a statistical method where samples are taken one after another from a lot, and the decision to accept or reject the lot is made based on the sample results. It continues until a decision is reached, using predefined acceptance and rejection criteria.

What are the different types of sequential sampling mentioned in the video?

-The two main types mentioned are 'Group Sequential Sampling' where multiple units are inspected together in one sample, and 'Item by Item Sequential Sampling' where a single unit is inspected at each stage.

How are acceptance and rejection decisions made in sequential sampling?

-Acceptance and rejection are determined by comparing the number of defectives found in the sample with predefined acceptance and rejection lines. If the cumulative defectives fall below the acceptance line, the lot is accepted; if they fall above the rejection line, the lot is rejected. If between, sampling continues.

What role does the Operating Characteristic (OC) curve play in sequential sampling?

-The OC curve shows the probability of acceptance based on the fraction of defectives in a lot. It helps visualize the effectiveness of the sampling plan by indicating the likelihood that a defective lot will be accepted or rejected.

How can the amount of sampling in sequential sampling be calculated?

-The amount of sampling is determined by the parameters 'a' and 'c', which can be calculated using the acceptance and rejection probabilities (alpha and beta), or by using known values of defect fraction probabilities (p1 and p2).

What is the Average Sample Number (ASN) in the context of sequential sampling?

-ASN refers to the average number of samples that will be inspected before making a decision on the lot. It is calculated using specific formulas that consider the lot acceptance and rejection processes.

What is the significance of the rectifying inspection in sequential sampling?

-Rectifying inspection is performed for rejected lots, where all defective items are inspected and replaced with good ones, ensuring that the outgoing quality is improved. This step helps prevent the shipment of defective products.

What is the relationship between the 'acceptance number' and 'rejection number' in sequential sampling?

-The acceptance number is the threshold number of defectives below which a lot is accepted, while the rejection number is the threshold above which a lot is rejected. These numbers help guide the sampling process.

How does the tabular method simplify sequential sampling decisions?

-The tabular method provides a predefined set of numbers (acceptance and rejection numbers) for different sample sizes, making the decision-making process easier and faster compared to graphical methods.

Why is sequential sampling considered more efficient than traditional sampling methods?

-Sequential sampling is more efficient because it adapts the sampling process based on the results of each inspection, often requiring fewer samples on average to make a decision, especially when the lot is clearly good or bad early on.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

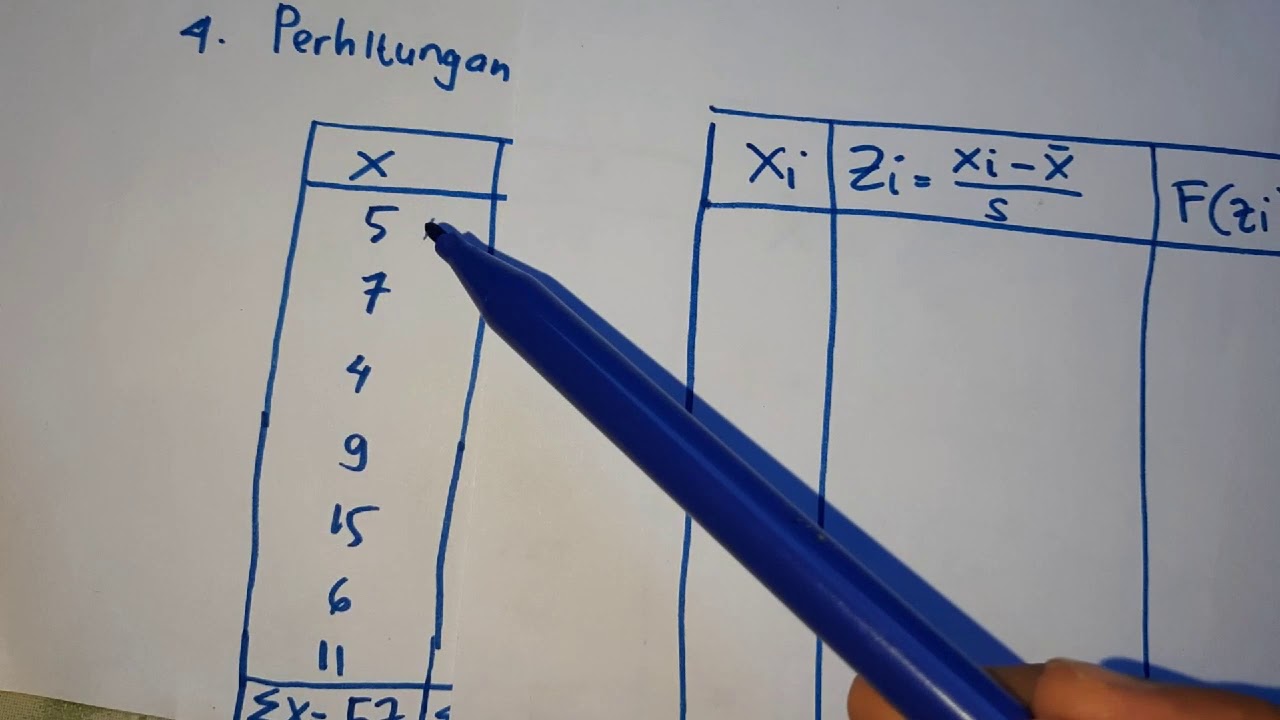

STATISTIKA : UJI NORMALITAS

[PART 3] TEKNIK SAMPLING NON PROBABILITAS

What is a Sampling Distribution? | Puppet Master of Statistics

Cara Pengambilan Sample (Sampling), SMK Farmasi Industri, PPMP, XI

Population ans Sampling for Mixed Research

Materi 6: Metode Penelitian Kuantitatif #edukasi #riset #sampling #eksperimen #korelasi #deskriptif

5.0 / 5 (0 votes)