I-35W Bridge Collapse Structure and Components and Initial Failure

Summary

TLDRThis animation explores the structural components of a bridge's deck truss. It details the support system, with piers numbered 5 through 8, and highlights the fixed bearing at Pier 7 and roller bearings at Piers 5, 6, and 8 for thermal expansion. The deck truss spans 1,640 feet and consists of upper, lower, diagonal, and vertical members connected by gusset plates. The non-redundant design means failure of one member could cause collapse. It also discusses the bridge deck, floor trusses, and supporting lateral and sway braces, providing an in-depth look at the materials and load distribution involved in the bridge's construction.

Takeaways

- 😀 The bridge's deck truss is supported by four piers, numbered Piers 5, 6, 7, and 8 from the south.

- 😀 Pier 7 has a fixed bearing, meaning the structure does not move relative to it, while Piers 5, 6, and 8 have roller bearings that allow for thermal expansion and contraction.

- 😀 The deck truss spans a total length of 1,640 feet, with the central span across the Mississippi River measuring 456 feet, and the North and South spans each 304 feet.

- 😀 The bridge design is non-redundant, meaning the failure of any individual truss member would result in the collapse of the entire structure.

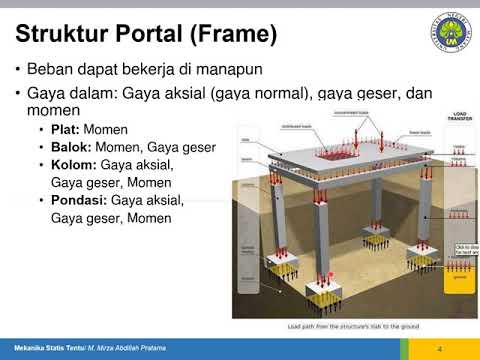

- 😀 The main trusses are made up of four types of members: upper chord, lower chord, diagonal, and vertical members.

- 😀 The truss members are connected using gusset plates, which are typically 1/2 to 1 inch thick and riveted, with some bolts used.

- 😀 Node numbering starts at 0 on the south end of the truss and continues to 14 in the center, with nodes on the north side labeled with a prime symbol.

- 😀 Trust members at node U10 experience both compression (blue) and tension (red) forces, with two members under compression and three under tension.

- 😀 The floor trusses extend between the main trusses to support the bridge deck, with lateral and sway braces stabilizing the structure.

- 😀 The bridge deck is made up of 14 deck stringers located above the upper chord of the floor trusses, supporting a reinforced concrete deck designed to be 6 1/2 inches thick with separate slabs for northbound and southbound lanes.

Q & A

What is the purpose of the roller bearings in the bridge's deck truss structure?

-The roller bearings at peers 5, 6, and 8 allow for the thermal expansion and contraction of the deck truss relative to the peers, ensuring the structure can adapt to temperature changes without damage.

Why is the bridge design considered non-redundant?

-The bridge's design is non-redundant because failure of any individual member in the truss would cause the collapse of the entire bridge. This means the structure does not have spare components to compensate for failures.

How were the truss members connected at the nodes?

-The truss members were connected at the nodes using gusset plates, typically one on each side of the node. These gusset plates were made from steel, ranging in thickness from 1/2 inch to 1 inch, and were riveted or bolted to the members.

What is the total length of the bridge's deck truss portion?

-The total length of the bridge's deck truss portion is 1,640 feet.

How long was the center span of the bridge across the Mississippi River?

-The center span of the bridge across the Mississippi River was 456 feet long.

What types of members make up the main trusses of the bridge?

-The main trusses of the bridge are composed of four types of members: upper chord members, lower chord members, diagonal members, and vertical members.

How were the nodes numbered on the truss?

-The nodes were numbered starting from zero on the south end of the truss and continued to 14 in the center. Nodes north of the center were denoted with a prime sign (e.g., U10 for upper nodes).

What types of loads were the truss members subjected to?

-Truss members were subjected to either compression loads (represented in blue) or tension loads (represented in red).

What was the original design of the deck's thickness and structure?

-The original deck design was 6 1/2 inches thick and consisted of two slabs: one for the northbound lanes and one for the southbound lanes, including median barriers and steel guard rails.

What role do the lateral braces and sway braces play in the bridge's structure?

-The lateral braces and sway braces were attached at each node to stabilize the structure, helping to prevent unwanted movement and ensuring the integrity of the bridge under various conditions.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

5.0 / 5 (0 votes)