FROM SEA TO CANS | THE SECRET BEHIND THE MAKING OF TONNO CALLIPO TUNA

Summary

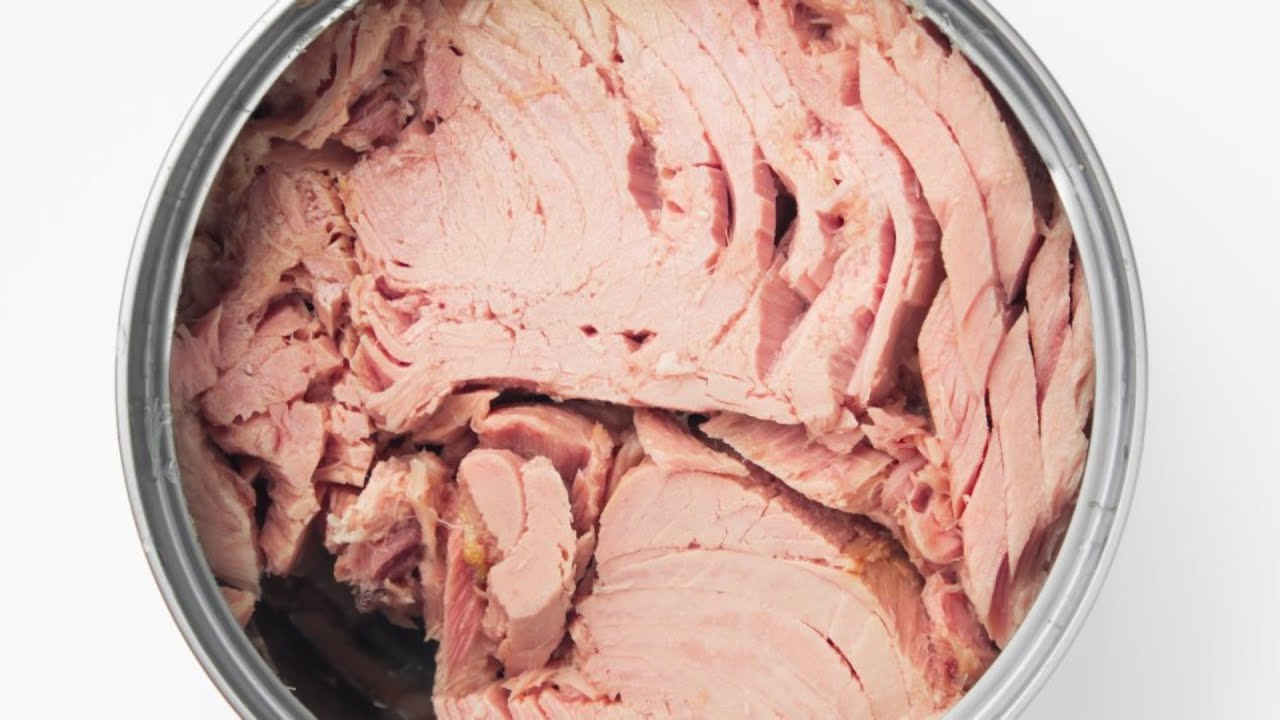

TLDRTonno Callipo is a renowned producer of premium canned tuna, known for its strict production processes. The video showcases the journey of their tuna, from its careful selection by fishermen to its processing in the factory. The tuna is steamed, cooled, and meticulously packaged in olive oil or salt water, ensuring high quality and nutrition. The final product undergoes sterilization for freshness and is carefully labeled before being distributed worldwide. This process ensures the tuna maintains its tender texture and delicious taste, making it a popular and convenient choice for consumers seeking a nutritious, versatile food.

Takeaways

- 😀 Tonno Callipo is known for producing premium quality canned tuna with strict production processes.

- 😀 Fresh tuna is carefully selected and processed with a mix of modern technology and manual touch at every stage.

- 😀 The product is made using high-quality additives like real olive oil, which enhances the taste and texture of the tuna.

- 😀 Canned tuna is a practical, nutritious, and long-lasting food option that is perfect for modern fast-paced lifestyles.

- 😀 It is a great source of protein and omega-3, making it a healthy option for balanced nutrition.

- 😀 Canned tuna is versatile, used in a wide range of dishes from salads to pasta.

- 😀 The journey of the tuna starts at the pier, where the fish are caught and stored in ice for freshness.

- 😀 After arrival at the factory, tuna is carefully inspected and frozen under optimal conditions.

- 😀 The tuna is then cut into precise sizes, with both modern machines and manual processes ensuring high-quality results.

- 😀 The tuna is steamed at a precise temperature to preserve its texture and nutritional content before being cooled and processed further.

- 😀 After being placed in containers (either tin or glass), the tuna is filled with olive oil or saltwater, sealed, and sterilized to ensure freshness and shelf life.

Q & A

What makes Tonno Callipo one of the most renowned canned tuna producers in the world?

-Tonno Callipo is renowned for its premium quality, strict production processes, and commitment to using fresh tuna, processed with both modern technology and a manual touch at every stage.

How does Tonno Callipo ensure the freshness and quality of the tuna?

-Tonno Callipo ensures the freshness and quality of the tuna by immediately storing the fish in ice after catching them and transporting them to the factory under optimal conditions to maintain their quality.

What role does technology play in the production of Tonno Callipo canned tuna?

-Modern technology plays an important role in speeding up processes like cutting and steaming the tuna. However, manual handling by trained workers ensures the perfect quality of the final product.

Why is the steaming process important in the production of canned tuna?

-The steaming process is crucial as it ensures the tuna meat retains its tenderness, texture, and nutritional content. The tuna is steamed at specific temperatures to achieve the best results.

What happens after the tuna is steamed and cooked?

-Once the tuna is steamed, it is stored in the freezer to cool down, making it easier to handle for further processing. Workers then inspect and cut the tuna into smaller sizes before packing it into containers.

What ingredients are used in the Tonno Callipo canned tuna products?

-For variants like tuna in olive oil, high-quality olive oil is used to enhance flavor and tenderness. Other variants, like tuna in saltwater, use a mixture of water and salt to preserve the natural taste of the tuna.

How does the packaging process work for Tonno Callipo canned tuna?

-After the tuna is placed in containers, they are filled with olive oil or saltwater. The containers are then tightly sealed using an automatic machine, and a vacuum system ensures no air remains inside, preserving freshness.

What is the purpose of the high-pressure sterilization process?

-The high-pressure sterilization process is used to kill harmful bacteria and extend the shelf life of the tuna without compromising its taste or texture.

How are Tonno Callipo canned tuna products labeled and prepared for distribution?

-Once the cans are sterilized, they are cooled and dried. An automatic machine then applies the signature Tonno Callipo label, which includes product details, nutritional information, and expiration dates. Finally, the products are packaged for distribution.

What are the key health benefits of canned tuna, according to the video?

-Canned tuna is a good source of protein and omega-3, making it a healthy alternative for those who care about balanced nutrition and want a quick, nutritious meal option.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)