The Most Tortured Part In An Engine

Summary

TLDRThis video delves into the intricate engineering behind the modern head gasket, a vital yet often overlooked component in internal combustion engines. It explores the extreme stresses and multifaceted requirements that head gaskets must endure, such as thermal cycling, high pressure, and exposure to volatile fluids. The evolution of head gasket materials, from early copper gaskets to modern multi-layer steel (MLS) designs, is examined, highlighting the importance of sealing combustion gases, coolant, and oil. The video also emphasizes the role of precision engineering in ensuring durability and performance, with a nod to the future of automotive technology.

Takeaways

- 😀 The head gasket is the most stressed component in a modern internal combustion engine, as it must withstand extreme mechanical and thermal forces.

- 😀 A head gasket seals critical passages like engine oil and coolant, and must endure varying temperatures, pressures, and the corrosive nature of fluids.

- 😀 Combustion gases, which can reach pressures up to 2200 PSI, are the most demanding aspect for a head gasket to contain, with additional challenges from abnormal combustion conditions like detonation.

- 😀 Head gaskets are subjected to constant thermal cycling, expansion and contraction, and mechanical stresses, making material choice and design highly critical for durability.

- 😀 The material evolution of head gaskets began with copper and evolved through various compounds such as copper-clad, steel shim, composite, and finally to Multi-Layer Steel (MLS) gaskets.

- 😀 Early head gaskets, including copper-based ones, were unreliable due to their inability to seal effectively under the extreme heat and motion experienced in engines.

- 😀 The introduction of the multi-layer steel (MLS) gasket in the 1970s revolutionized head gasket technology, providing higher durability and performance, especially in high-performance applications.

- 😀 MLS head gaskets consist of several layers of stainless steel, which allows them to be both springy and highly resistant to combustion pressure while also allowing easy adjustments for specific engine needs.

- 😀 Composite head gaskets, made from materials like elastomers, fibers, and graphite, are cost-effective but are more prone to failure from overheating or detonation.

- 😀 The development of head gaskets has been integral to improving the performance and reliability of engines, and while MLS technology remains dominant, specialized solutions like solid copper gaskets are still used in motorsport applications.

- 😀 Brilliant, a learning platform, is highlighted for its ability to develop analytical thinking through interactive courses, particularly in STEM areas like algebra and problem-solving.

Q & A

What is the most stressed component in an internal combustion engine?

-The most stressed component in an internal combustion engine is the head gasket. It must cope with volatile fluids, varying temperatures, combustion pressure, and thermal cycling while being compressed under significant clamping force.

How does a head gasket differ from a seal?

-A head gasket is technically not a seal. Seals are used on moving components, while gaskets are used on static ones. The head gasket seals the space between the engine block and head, containing fluids like engine oil, coolant, and combustion gases.

What are the primary functions of a head gasket?

-The head gasket serves to seal the passages for engine oil and coolant, prevent combustion gases from leaking, maintain the integrity of the combustion chamber, and handle thermal and mechanical stresses within the engine.

What challenges does a head gasket face in sealing combustion gases?

-Head gaskets must seal combustion gases under extremely high pressures (up to 2700 PSI in diesel engines), temperatures exceeding 2500°C, and the mechanical stresses of repeated thermal cycling and combustion forces.

What materials are commonly used in the construction of head gaskets?

-Head gaskets have evolved from using materials like leather, paper, copper, and rubber to more modern materials such as multi-layer steel (MLS) with coatings like fluorocarbon, elastomers, and graphite.

What is the key advantage of multi-layer steel (MLS) head gaskets?

-MLS head gaskets offer superior performance due to their layered construction, which allows them to tolerate surface imperfections and thermal expansion. They are also more resistant to combustion forces and do not require re-torquing of head bolts.

Why are MLS head gaskets more forgiving than other types?

-MLS head gaskets are forgiving because their multiple layers, combined with their spring-like properties, allow them to absorb thermal expansion and surface deviations without compromising the seal.

How did the beater ad process revolutionize head gasket manufacturing?

-The beater ad process enabled the production of composite head gaskets by using a slurry of elastomers, fibers, and fillers. This method made gaskets more cost-effective, and the resulting gaskets were both compressible and resilient.

What were some common failures of early head gaskets used in motorsports?

-Early head gaskets in motorsports often failed due to oil leakage, especially in high-performance engines, causing race cars to not finish races. This was mainly due to the inability of gaskets to withstand the extreme thermal and mechanical stresses.

What is the role of fire rings in head gaskets?

-Fire rings, which are metal rings embedded in gaskets, help seal the combustion chamber. They are especially important in high-performance applications like solid copper gaskets, as they help withstand high combustion pressures.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Aula 01 - Introdução aos motores de combustão interna

Types of Spark plugs | Which is Best?

Car Engine Parts & Their Functions Explained in Details | The Engineers Post

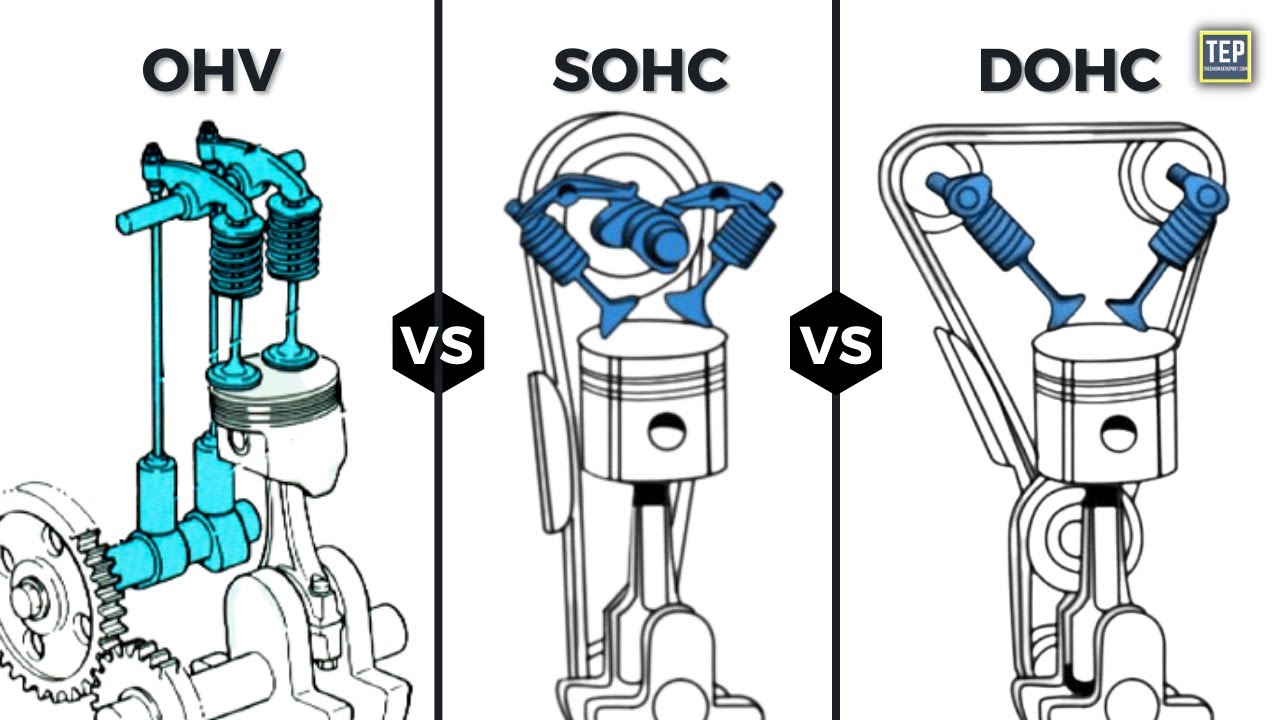

Which is the Best Engine Valvetrain Design? OHV, SOHC, DOHC or Flathead | Pros and Cons

Perbedaan Motor Pembakaran Dalam Dan Motor Pembakaran Luar | BeOto Channel | Video Part 1

Bagaimana cara kerja Mesin Jet?

5.0 / 5 (0 votes)