How Jacobsen Salt Company Harvests the Best Finishing Salt in America — Vendors

Summary

TLDRThis video showcases a small but dedicated salt-making company located on the Oregon coast, specializing in pure, high-quality flake and kosher sea salts. The process begins with harvesting seawater from the high-salinity Netarts Bay, followed by a meticulous process involving reverse osmosis, evaporation, and careful filtration. The focus is on producing clean, briny salt, free from impurities, with each batch being carefully monitored for quality. The salt is then harvested by hand and processed into unique infused salts, enjoyed by chefs across the country. The video highlights the artistry, dedication, and natural beauty behind every flake of salt produced.

Takeaways

- 😀 The company produces pure flake salt and kosher sea salt from seawater on the Oregon coast, one of the few companies in the U.S. doing so.

- 😀 Netarts Bay, where the company sources its seawater, is particularly special due to its high salinity and the presence of tens of millions of oysters that filter seawater, enhancing the water's quality.

- 😀 The process involves pumping seawater through a reverse osmosis unit to concentrate the salt, which is then used in salt-making.

- 😀 The salt-making process emphasizes purity, using heat and filtration to remove impurities like calcium and magnesium, resulting in a clean sodium chloride crystal.

- 😀 The flavor of the salt is described as clean, briny, and occasionally sweet, due to the lack of impurities.

- 😀 The timing of the salt's harvest is crucial; if harvested too early or late, it can affect the quality and texture of the salt.

- 😀 Once harvested, the salt is gently drained, rinsed, and placed in dehydrators to remove any remaining moisture.

- 😀 Post-production involves sifting the salt to separate kosher salt, flake salt, and pure flake salt, with every flake inspected for quality and impurities.

- 😀 Pure flake salt is rare and highly prized, requiring multiple batches to collect small quantities, with each flake hand-inspected for perfection.

- 😀 The company offers a variety of infused salts, with rosemary and black garlic salts being particularly popular, providing unique flavors for chefs and food enthusiasts.

Q & A

What makes the salt production process in Netarts Bay unique?

-Netarts Bay's uniqueness lies in its high salinity and the presence of tens of millions of oysters. Oysters filter seawater, keeping it clean, which is essential for producing high-quality salt.

Why is reverse osmosis used in the salt-making process?

-Reverse osmosis is used to desalinate seawater, removing fresh water and increasing the concentration of salt in the brine, which is crucial for producing pure salt.

How does the salt-making facility ensure the purity of the salt?

-The facility uses a multi-step process, including reverse osmosis, boiling, and filtration, to remove impurities like calcium and magnesium, ensuring that the final salt is clean and pure.

Why is the timing of harvesting salt so important?

-Timing is critical because harvesting too early can agitate the brine, affecting evaporation rates and salt quality. If harvested too late, salt flakes may bond together, making them difficult to separate.

What role do temperature and environment play in the salt-making process?

-Environmental factors such as temperature and humidity impact the evaporation rate, which in turn affects the boil process and the quality of the salt produced.

What is the significance of 'pure flake' salt, and why is it rare?

-Pure flake salt forms naturally and has a unique structure. It is rare because it requires a perfect combination of conditions during the evaporation process, making it difficult to produce.

How do the salt flakes form during the evaporation process?

-Salt flakes form through a precise combination of time, temperature, and the mineral composition of the brine. The crystals form at the surface and fall gently to the bottom, creating a pyramid-like structure.

Why do the workers use special shovels to harvest the salt?

-The special shovels have holes to allow excess brine to drain as the salt is harvested. This prevents unwanted liquid from contaminating the salt and ensures its purity.

What happens to salt that doesn’t meet the quality standards?

-Salt that doesn’t meet quality standards is discarded or used in the boil process to create a new batch, ensuring minimal waste and maintaining quality in the final product.

How do infused salts, such as rosemary and black garlic, enhance the flavor?

-Infused salts, like rosemary and black garlic, enhance flavor by adding distinct tastes to the salt. Rosemary adds a vibrant green flavor, while black garlic provides a rich umami profile due to its fermentation process.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Know the 12 TYPES OF SALT and each uses.

Himalayan vs. Celtic Sea Salt: WHICH IS BETTER?

Which water softener salt is best?

The Hidden Dangers Of Excessive Salt Consumption

How to Render and Purify Tallow | ODORLESS, WHITE, WET METHOD | Bumblebee Apothecary

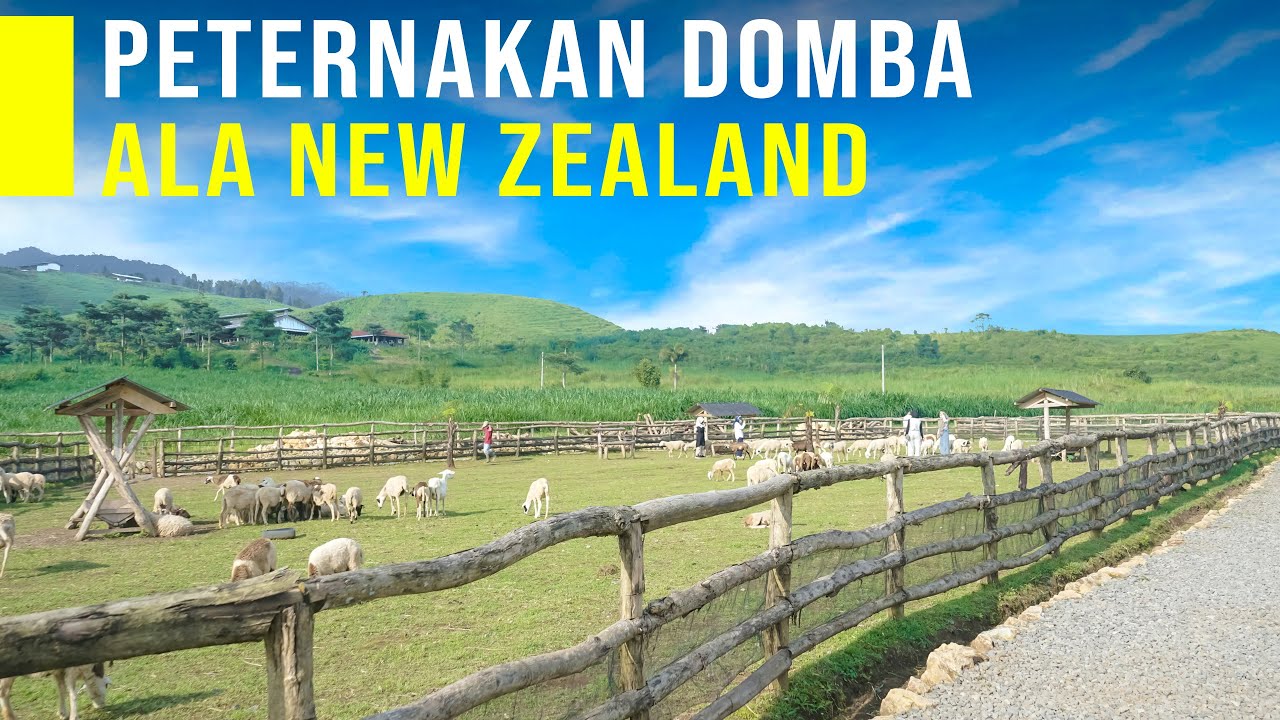

Peternakan Domba Modern dan Bersih, New Zealand nya Jawa

5.0 / 5 (0 votes)