Pembubutan Menggunakan Taper Attachment || Teknik Pemesinan Bubut @Murdiyono

Summary

TLDRThis video lesson focuses on teaching students how to use a taper attachment on a lathe machine for creating precise external and internal tapers. It explains the various components of the taper attachment, their functions, and the steps involved in setting up and operating it effectively. The tutorial highlights key aspects such as adjusting angles, securing the workpiece, and ensuring smooth machine operation. The lesson also includes practical tips for calculating taper angles and troubleshooting. The session concludes with an assignment to summarize the material, ensuring a solid understanding of the concepts discussed.

Takeaways

- 😀 Taper turning involves creating a conical shape on a workpiece using a taper RT attachment on a lathe machine.

- 😀 The taper RT attachment is used for both internal and external tapering and requires careful setup on the lathe.

- 😀 There are three methods for taper turning: shifting the headstock, adjusting the cross-slide, and using the taper RT attachment for long tapers.

- 😀 The taper RT attachment is installed using bolts and connected to the lathe’s cross-slide to adjust the taper angle.

- 😀 Proper installation of the taper RT attachment includes mounting it at the back of the lathe headstock and ensuring all components are secured.

- 😀 The attachment’s guide shaft needs to be clean and smooth for optimal performance and the correct taper angle.

- 😀 Taper turning with the attachment is most efficient for long tapers (greater than 30 cm) and is less effective for short tapers.

- 😀 The attachment allows users to set the desired taper angle by adjusting the cross-slide, making it versatile for different taper sizes.

- 😀 The machining process requires checking for proper setup, including ensuring the cutting tool is aligned and the correct angle is set.

- 😀 The key to successful taper turning is understanding the function of each part of the taper RT attachment, such as the guide shaft and support brackets.

- 😀 The lesson includes a task where students summarize key points from the material, demonstrating their understanding of taper turning with the RT attachment.

Q & A

What is the purpose of the taper attachment in lathe machines?

-The taper attachment is used as an auxiliary device on a lathe machine to perform the turning of both external and internal tapers, particularly for long tapers that cannot be achieved using other methods.

What are the three methods for creating a taper mentioned in the script?

-The three methods for creating a taper are: 1) Moving the tailstock, 2) Using the cross slide, and 3) Using the taper attachment.

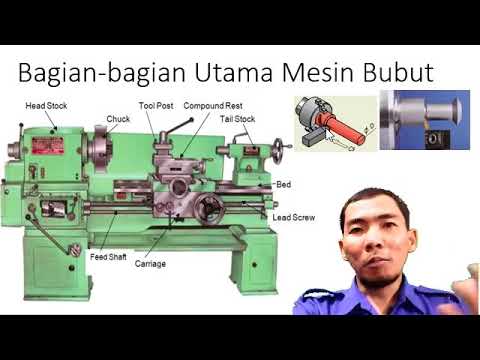

What parts are involved in the taper attachment setup?

-The key parts of the taper attachment include the clamping bolts, the feed shaft, the cross slide, the support brackets, and the taper guide or follower.

How does the taper attachment improve the accuracy of taper cutting?

-The taper attachment allows for precise control of the taper angle by adjusting the feed shaft and cross slide. This adjustment helps in creating a smooth, accurate taper over a long length of material.

What is the importance of maintaining the cleanliness and smoothness of the feed shaft in the taper attachment?

-The feed shaft must be clean and smooth to ensure that the taper attachment moves accurately and smoothly during operation, thus achieving a precise taper.

What does the script suggest about the application of taper attachments on lathe machines?

-The taper attachment is typically used for creating long, consistent tapers that require precise angular adjustments. It is not needed for short tapers or simple jobs.

How does the setup of the taper attachment differ from other lathe attachments?

-Unlike other lathe attachments that are often directly attached to the machine, the taper attachment is installed and adjusted on the cross slide and requires careful calibration before use.

What steps should be taken before starting the turning process with a taper attachment?

-Before starting, one must check the machine condition, clean the lathe and tool, ensure the workpiece is properly secured, set the taper angle on the attachment, and ensure that the cutting tool is aligned with the center of the workpiece.

What is the role of the clamping bolts in the taper attachment?

-The clamping bolts secure the parts of the taper attachment in place, ensuring that the feed shaft and other components remain steady during the cutting process.

What is the final step mentioned in the script for completing the taper turning process?

-The final step is performing the finishing operation to refine the taper, after which the machine should be turned off, and the lathe and workspace should be cleaned and maintained.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade Now5.0 / 5 (0 votes)