Faults & Maintenance Methods of Steam Turbine in Thermal Power Plant | Steam Turbine Faults & Maint.

Summary

TLDRThis video provides an in-depth analysis of the common faults and maintenance methods for steam turbines in thermal power plants. It explains the critical role steam turbines play in power generation, the types of faults they can experience, such as abnormal vibration and thermal deformation, and offers solutions for maintaining their stability. Emphasizing the importance of accurate fault diagnosis, routine maintenance, and skilled personnel, the video stresses how effective maintenance practices can improve the reliability of turbines, reduce downtime, and ensure optimal power plant operation.

Takeaways

- 😀 Steam turbines are critical to the operation of thermal power plants, converting steam into kinetic energy to generate electricity.

- 😀 Regular maintenance and effective fault management are vital for ensuring the stable operation of steam turbines and preventing costly failures.

- 😀 Common faults in steam turbines include abnormal vibration, which can be caused by factors like gas excitation, rotor deformation, and imbalance.

- 😀 Abnormal vibration in steam turbines can be classified into normal vibration, abnormal forced vibration, and self-excited vibration.

- 😀 Abnormal vibration can often be mitigated by reducing the turbine load or by addressing the root cause, such as rotor bending or steam flow imbalance.

- 😀 Thermal deformation of the rotor is a significant issue that can cause imbalance and vibration, particularly during long-term operation under high pressure and temperature.

- 😀 Steam turbine shaft misalignment can lead to defects in coupling and affect the turbine's operational stability, requiring careful centering during maintenance.

- 😀 Routine monitoring of the turbine’s performance is essential to detect signs of abnormal vibration or imbalance early and address them promptly.

- 😀 Preventive maintenance, including rotor tempering and alignment, is crucial to maintaining turbine efficiency and reducing the likelihood of faults.

- 😀 Training personnel in both theoretical knowledge and hands-on experience is essential for accurate fault diagnosis and effective maintenance of steam turbines.

Q & A

Why is the steam turbine critical in thermal power plants?

-The steam turbine is essential in thermal power plants because it converts steam into mechanical energy, which is further converted into electrical energy. Its proper operation is vital for ensuring efficient and stable electricity production in the plant.

What are the consequences of faults in steam turbines?

-Faults in steam turbines can lead to reduced operational efficiency, instability in power generation, equipment damage, and economic losses for the thermal power plant. In extreme cases, it may result in plant shutdowns.

What are the main components of a steam turbine?

-A steam turbine consists of a rotating portion (rotor) and a fixed portion (stator). The rotating parts include components like the impeller, main shaft, and coupling, while the fixed parts include the cylinder, steam chamber, bearings, and engine base.

What causes abnormal vibration in steam turbines?

-Abnormal vibration in steam turbines can be caused by factors such as unbalanced gas flow, thermal deformation of the rotor, misalignment of coupling parts, and mechanical issues like cracks in the rotor or loose bolts in the coupling.

How can abnormal vibration in steam turbines be resolved?

-To resolve abnormal vibration, it is crucial to reduce the load on the turbine and address the underlying causes, such as adjusting the high-pressure speed control valve, addressing thermal deformation of the rotor through rotor tempering, and correcting misalignments.

What is the role of thermal deformation in abnormal vibration?

-Thermal deformation occurs when the rotor's temperature increases during operation, causing it to bend. This deformation leads to unbalanced forces that generate vibrations. Proper monitoring and rotor maintenance are needed to reduce thermal deformation.

What maintenance practices are essential for the steam turbine’s stability?

-Essential maintenance practices include monitoring vibration levels, regularly inspecting and maintaining the rotor and shaft for alignment and deformities, controlling the operating environment (temperature and humidity), and conducting routine checks to ensure the system is functioning optimally.

Why is it important to maintain the rotor and shaft of a steam turbine?

-Maintaining the rotor and shaft is crucial because long-term operation can lead to thermal deformation and misalignment, affecting the turbine's performance and causing abnormal vibrations. Regular maintenance helps avoid these issues and ensures the stable operation of the turbine.

What are the types of abnormal vibration in steam turbines?

-There are three main types of abnormal vibration: normal vibration (due to imbalance), abnormal forced vibration (caused by loose parts or cracks), and self-excited vibration (due to thermal deformation of the rotor or high-pressure airflow excitation).

How can the efficiency and stability of steam turbine operations be improved?

-Efficiency and stability can be improved by conducting regular maintenance, monitoring the turbine’s performance, addressing faults promptly, ensuring proper environmental conditions, and training maintenance personnel to handle common issues effectively.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Materi Pelatihan Pembangkit Listrik Tenaga Uap (PLTU).

How does a Steam Turbine Work?

Bagaimana cara kerja pembangkit listrik tenaga termal/uap?

OscardaFisicaIITermoLata - Experimento de Termodinâmica da latinha

Termofluida W10 - Part 2. Pembangkit Listrik Tenaga Uap [Rankine Cycle]

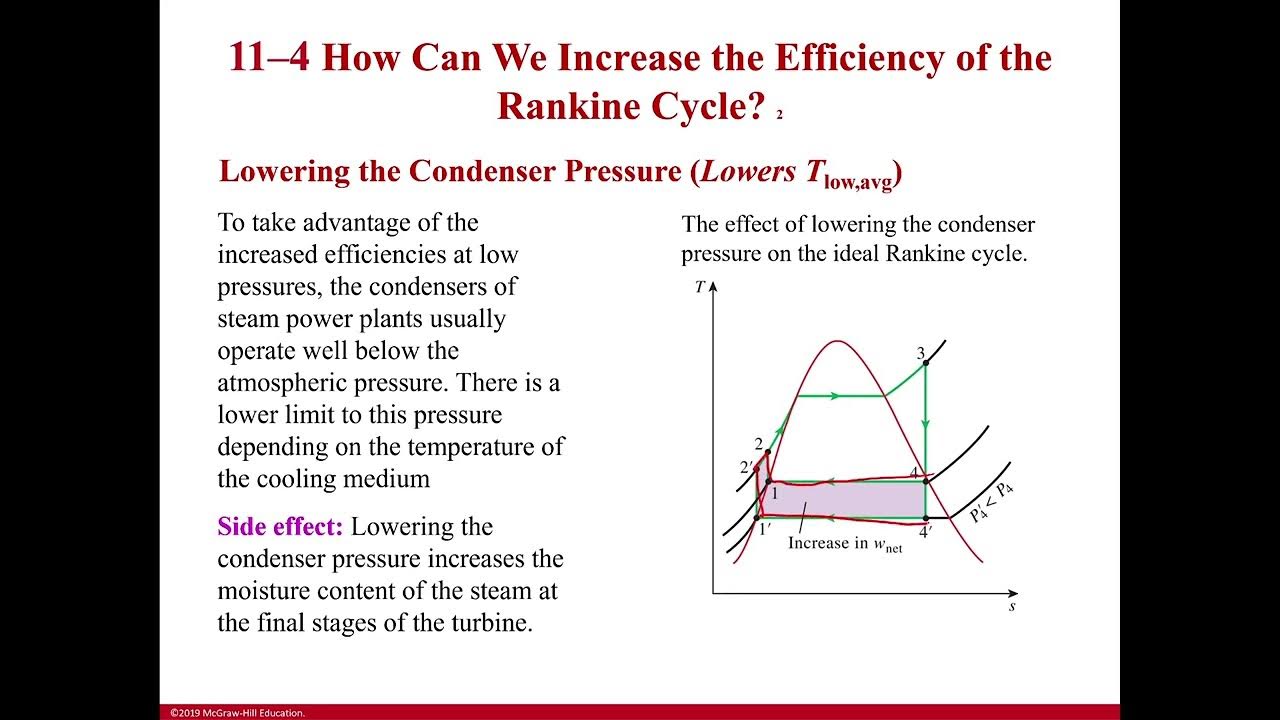

Increasing Efficiency of the Rankine Cycle

5.0 / 5 (0 votes)