PROSES OVERHAUL TURBINE

Summary

TLDRThis video takes viewers through the detailed process of a turbine overhaul, specifically focusing on the removal and installation of the flywheel and bearings. The procedure includes the use of heavy machinery like cranes and hydraulic tools to safely disassemble components, clean parts, and install new bearings. Emphasis is placed on the precision required in handling gears, coupling, and bearings. The video also highlights the material properties of turbine blades, which are made of stainless steel for durability. Overall, the video provides an in-depth look at the complex process of turbine maintenance and overhaul.

Takeaways

- 😀 The process involves the release of the flywheel and wheel set from the VS frame or mounting structure.

- 😀 Hydraulic tools are used for several steps, including the removal of coupling gears and bearings.

- 😀 The purpose of the overhaul process is to simplify future bearing removal, specifically for turbines.

- 😀 The flywheel mounting structure is described as having bearings and coupling gears, which need to be removed and cleaned.

- 😀 The bearings used in the process are spherical, sourced from QSFX Germany, and are of high quality.

- 😀 The coupling gears are cleaned and prepared before being reinstalled, ensuring smooth operation.

- 😀 The bearing removal process involves using hydraulic equipment to extract the bearings from the shaft.

- 😀 The turbine blade is made of stainless steel, making it resistant to corrosion and rust.

- 😀 After bearing removal, the bearing mounts are cleaned with thinner or gasoline to ensure a smooth reinstallation.

- 😀 New bearings are installed carefully, with the goal of improving the performance and longevity of the turbine.

- 😀 The video concludes with an invitation to subscribe and share, aiming to educate viewers about turbine overhauls.

Q & A

What is the main purpose of the 'flywheel release' process described in the video?

-The main purpose of the flywheel release process is to facilitate the removal of the bearing, shaft, and related components during the overhaul of the turbine. This makes future maintenance easier.

What equipment is used to assist with the bearing removal process?

-Hydraulic tools are used to assist with the bearing removal process, as mentioned during the video when the gear coupling and bearing are removed.

What type of bearing is used in the overhaul process?

-The bearings used in this overhaul process are spherical bearings, specifically of the QSFX German type.

What is the purpose of the 'coupling gear' mentioned in the video?

-The coupling gear connects the shaft to other parts of the system. It is removed during the overhaul to access the bearings and other components that require maintenance or replacement.

What materials are used for the turbine blade in the video?

-The turbine blade is made of stainless steel, which is resistant to corrosion and rust, ensuring durability and performance in harsh conditions.

What is the role of the bearing 'dudukan' (bearing seat) in the process?

-The bearing seat (dudukan) is crucial for holding the bearings in place. During the overhaul, the seat is removed to allow for the replacement of bearings and proper reinstallation of components.

How many bearings are used in the system, as mentioned in the video?

-There are three bearings used in the system, located at the end of the shaft, which are all removed and replaced during the overhaul process.

What cleaning process is applied to the components during the overhaul?

-The components are cleaned using solvents like thinner or gasoline to remove any debris, dirt, or residues that might affect the function of the parts.

What is the final step in the bearing installation process?

-The final step involves inserting the new bearing into its seat, followed by securing it and ensuring that it functions properly within the turbine system.

How does the video conclude, and what is the message to viewers?

-The video concludes by summarizing the entire turbine overhaul process and encouraging viewers to support the channel by subscribing and sharing the video. The host thanks viewers for their attention and expresses hope that the video is helpful.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

👉 CONDUÍTE entupido na LAJE nunca MAIS: RESOLVIDO! 🙌

EP5 demontage d'un moteur asynchrone - remontage des roulements

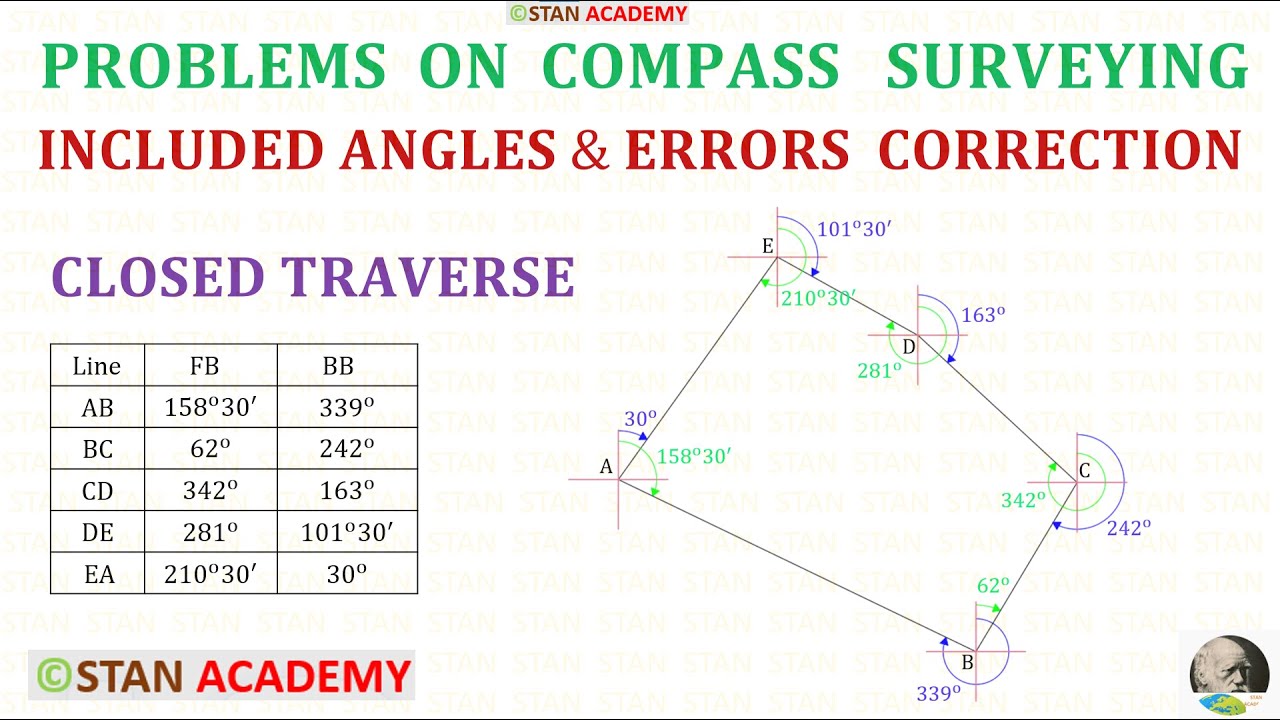

Compass Surveying - Problem No 3 ( Included Angles & Error Correction of a Closed Traverse )

How to Align the Sheave to the Flywheel and Set Proper V-Belt Tension

Automotive Wheel Hub and Bearings

Cara Menentukan Posisi Kapal dengan baringan Silang

5.0 / 5 (0 votes)