Materi Periodical Service Mayor HD785-7 | PS 2000H (Irfan Amiruddin)

Summary

TLDRThis video provides a detailed guide on performing maintenance tasks for heavy machinery, focusing on components such as suspension, nitrogen filling, and oil checks. The process involves adjusting height, ensuring oil levels are correct, and checking various parts like the frame, suspension, and lights. The technician also demonstrates how to use vacuum pumps for oil sampling, adjust gear oil, and ensure proper tightening of parts with specific torque settings. The tutorial is aimed at ensuring optimal performance and longevity of the equipment.

Takeaways

- 😀 Height calibration is essential, aiming for a measurement of 199 mm ± 10/20 mm (approximately 20 cm).

- 😀 If the height is not standard, nitrogen is released from the system, and adjustments are made using a jack.

- 😀 After adjusting the height, oil leveling is performed by adding oil and ensuring it is at the correct level before refilling nitrogen.

- 😀 The nitrogen height should be set to the required 199 mm or 20 cm to ensure proper functioning.

- 😀 Breeder and differential components should be cleaned regularly, similar to the process for transmission breeder cleaning.

- 😀 Checking the condition of lamps and suspension style is part of routine maintenance, ensuring they function properly.

- 😀 Lubrication checks should be performed to ensure that all moving parts are properly lubricated.

- 😀 Visual inspection of the frame is done using a color checker to identify any potential issues, though visual inspection is usually sufficient.

- 😀 The projector should be checked to ensure it is not obstructed during use.

- 😀 Recovery oil levels are checked, and necessary replacements are made using SA50 oil for proper system operation.

- 😀 Grinding procedures for plates are carried out with specific pressure values (15 kg for the plate and 5-6 kg for the grinding process).

Q & A

What is the purpose of adjusting the nitrogen levels in the system?

-The nitrogen levels are adjusted to ensure the correct height of the suspension, which is specified as 199 millimeters plus or minus 10-20 millimeters. This ensures that the system operates at optimal levels.

What is the first step to adjust the nitrogen levels?

-The first step is to release the nitrogen from the system before adjusting the height or replacing any fluids.

What tools are used for adjusting and checking the oil level in the system?

-The system uses a leveling process where oil is added and then the nitrogen is refilled. A suction valve or vacuum pump is used to take samples or adjust fluid levels.

How do you ensure that the components are properly sealed during maintenance?

-The components are sealed by ensuring that the block is properly tightened with a two-centimeter seal, which is checked for proper sealing before proceeding with other maintenance steps.

What does the visual check for the frame and suspension involve?

-The visual check involves inspecting the frame for any potential issues using a color checker or by simply observing it to detect any visible damage. The suspension is also checked for lubrication and function.

Why is it important to check the condition of the lights and projectors?

-Checking the lights and projectors ensures they are working correctly and that nothing is obstructing their movement, which is essential for safe operation.

What is the procedure for cleaning the breeder differential?

-The cleaning procedure for the breeder differential is similar to that of cleaning the breeder in the transmission. It involves making sure all components are free from debris and operating correctly.

How is the oil in the recovery system maintained?

-The oil in the recovery system is maintained by checking and topping up the oil to the correct level using a suction valve or vacuum pump. The proper oil weight, such as SA50, is used for this process.

What is the significance of using the correct oil weight in the system?

-Using the correct oil weight, such as SA50, ensures that the system functions efficiently and prevents any operational issues caused by incorrect lubrication.

What is the procedure for replacing the polifenol weight in the system?

-The polifenol weight is replaced by filling the system with the correct solution, adjusting the level to the appropriate line, and ensuring proper sampling with the suction valve or vacuum pump.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

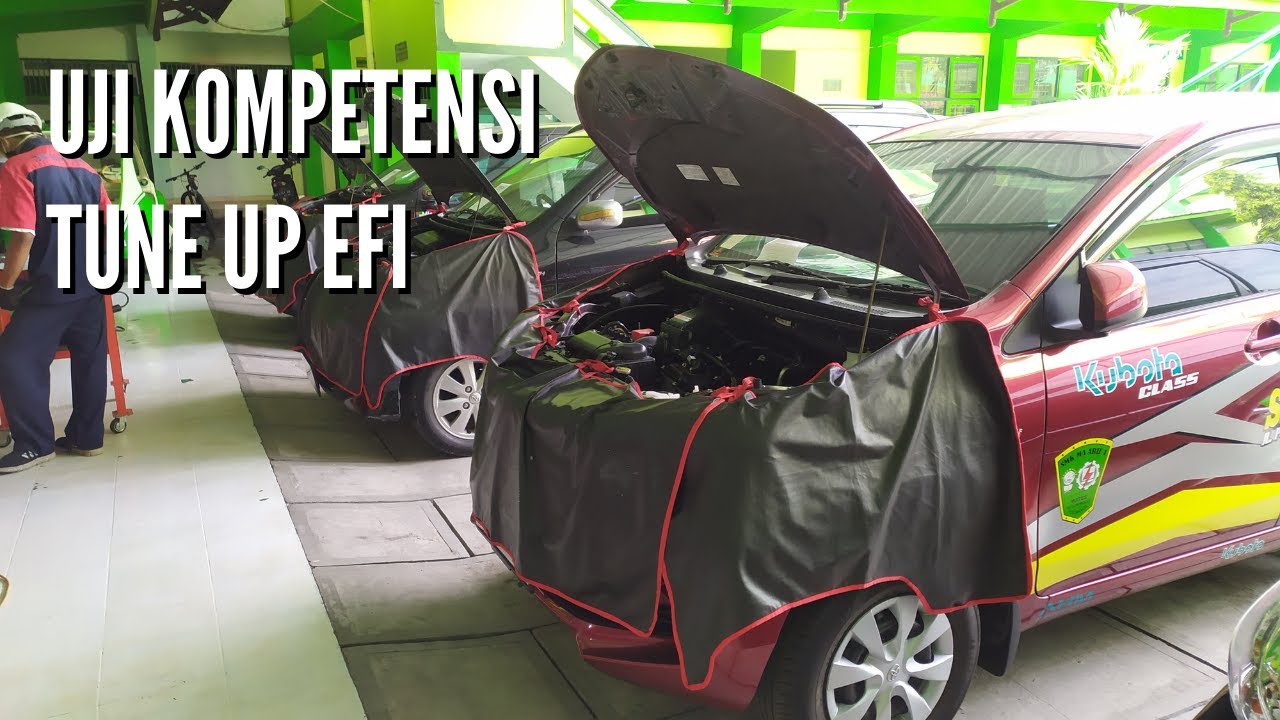

TUNE UP EFI - UKK TUNE UP EFI - UJI KOMPETENSI EFI - UJIAN PRAKTIK TKR

SOP Service Berkala Motor Injection "YAMAHA MIO SOUL GT"

Cara Service 250 dan 500 jam PC200 Komatsu

Materi PMKR Tune Up Mesin Bensin Konvensional 🛠🛠

Tutorial Praktis Perawatan Mesin Traktor agar Selalu Fit

Tips for your First Service on a Motorcycle (600 miles)

5.0 / 5 (0 votes)