Learning how to TIG weld made easy

Summary

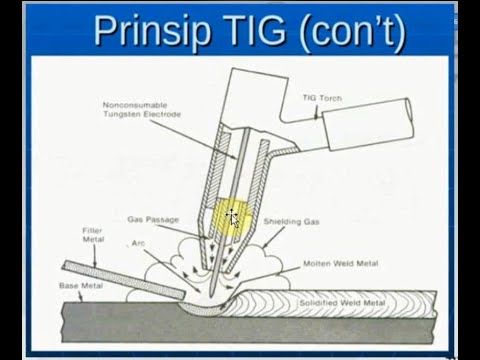

TLDRThis video offers an introductory guide to TIG welding, focusing on key techniques for beginners. It covers essential steps like turning on the torch, ensuring proper gas coverage, and maintaining a steady hand while welding. The tutorial emphasizes the importance of cleanliness, avoiding contamination, and properly using the filler rod to prevent porosity. It also shares tips on controlling heat, breaking the arc, and safely finishing the weld. The video concludes with a reminder to always turn off the argon gas to avoid leaks. Ideal for those starting with TIG welding or looking to refine their technique.

Takeaways

- 😀 Get comfortable with your torch height and technique before starting. Relaxation is key for smooth welding.

- 😀 Always clean your workpiece thoroughly to avoid contamination, which can cause porosity and splatter.

- 😀 When welding, maintain a steady height with your torch and keep the filler rod close to the tungsten to ensure gas coverage.

- 😀 Avoid pulling the filler rod in and out of the weld area, as it introduces oxygen and can result in poor weld quality.

- 😀 Start your weld by holding the torch steady until you see a liquid weld puddle before adding the filler rod.

- 😀 Every time you add filler rod, the puddle will cool down, so maintain a steady addition to avoid inconsistent results.

- 😀 When finished with the weld, break the arc and let the shielding gas run for 6-8 seconds to cool the weld area and reduce porosity.

- 😀 Adjust your welder's amperage based on the material's thickness and your comfort level, as temperatures that are too high or low can affect the weld.

- 😀 Don't forget to turn off your argon gas valve after welding, as a small leak could waste the gas and empty the bottle.

- 😀 TIG welding is an excellent technique for detail work and thin metals, such as aluminum or small-scale projects like hydraulic tanks.

Q & A

Why is it important to maintain a consistent height off the metal while TIG welding?

-Maintaining a consistent height off the metal ensures proper control of the arc and prevents overheating or poor weld quality. It also contributes to comfort and reduces the risk of breaking the arc.

What is the impact of bringing the filler rod in and out of the weld area?

-Bringing the filler rod in and out of the weld area introduces oxygen, leading to porosity and contamination in the weld. Keeping the filler rod close to the tungsten minimizes this risk.

Why should you always clean the material before welding?

-Cleaning the material ensures there is no contamination like mill slag, rust, or oils, which can negatively affect the weld by causing porosity or splatter.

What is the proper technique for adding filler rod during a TIG weld?

-The filler rod should be added steadily without moving it in and out of the weld puddle. The torch should remain at a consistent height, and the filler rod should be introduced gradually to avoid cooling the weld too quickly.

How can improper gas shielding affect your weld?

-Improper gas shielding can lead to contamination of the weld, including porosity, by allowing oxygen to mix with the molten metal. Proper shielding ensures a clean weld with minimal defects.

What should you do after completing a TIG weld?

-After completing a weld, break the arc, pull out the filler rod, tilt the torch back, and hold the shielding gas on the weld for 6-8 seconds to allow proper cooling and prevent porosity.

How do you determine the right amperage for welding with TIG?

-The right amperage depends on the material thickness and the type of metal being welded. For instance, 120 amps worked well initially but was adjusted to 110 amps for better control and a cooler weld puddle.

What is the risk of not turning off your argon gas after welding?

-Leaving the argon gas on after welding can result in a slow leak, which can waste gas, especially if it is left unchecked over time, leading to an empty gas tank when you return.

What kind of welding projects benefit from TIG welding?

-TIG welding is particularly useful for welding thin metals, performing detailed work, and aluminum welding, making it ideal for projects like hydraulic tanks and precision work on vehicles.

What does the speaker's experience with TIG welding suggest about learning the technique?

-The speaker's experience suggests that TIG welding is a skill that can be learned through practice and self-teaching, even if you're not initially a professional welder. With persistence, you can become proficient and achieve quality results.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

DASAR-DASAR & PENGERTIAN SEMUA JENIS TIPE PENGELASAN UNTUK PEMULA

Welding Basics for Beginners

Prinsip Kerja dan Komponen Las TIG (Tungsten Inert Gas)

belajar las Tig/Argon pada media besi||teknik dasar

Method, Crack Inspections & Symbol of Welding | Shielded Metal Arc Welding (SMAW) | Steel Structure

Common 13 Types of Sheet Metal Fabrication Techniques

5.0 / 5 (0 votes)