You May Not Like It But this Is What Peak Combustion Technology Looks Like - Rotary Vane Engine

Summary

TLDRThis video delves into the concept of rotary engines, specifically focusing on the Wankel engine, its limitations, and the potential of the rotary vane engine as the ultimate combustion engine. It highlights the advantages of rotary vane engines, including zero reciprocation, better power-to-weight ratios, smoother operation, greater torque at lower RPMs, and higher efficiency. The video explores the challenges of sealing and friction in these engines and argues that despite obstacles, their potential is immense. It concludes with a call for innovation and further attempts to develop this technology, offering a fresh perspective on the future of combustion engines.

Takeaways

- 😀 The Wankel engine, known for its smoothness and power-to-weight ratio, is a ‘beautiful failure’ due to its lack of torque, emissions control, fuel economy, and longevity.

- 😀 The rotary engine has one major advantage over traditional piston engines: it doesn’t require conversion of reciprocation into rotation, leading to fewer vibrations and mechanical complexity.

- 😀 Traditional piston engines are inherently less efficient because they rely on a reciprocating piston and connecting rods, introducing vibrations and requiring a crankshaft for rotation.

- 😀 The ultimate internal combustion engine should be a rotary engine, specifically the rotary vane engine, which eliminates many of the shortcomings of piston and Wankel engines.

- 😀 The rotary vane engine operates with a circle rotating inside an ellipse, with vanes that compress the air and create combustion events, offering more power and torque.

- 😀 The rotary vane engine is more power-dense, compact, lightweight, and efficient than both the piston and Wankel engines, with fewer moving parts and zero vibrations.

- 😀 The vane engine's design allows for constant torque throughout the combustion stroke, making it better suited for generating massive low RPM torque, much like an electric motor.

- 😀 Unlike traditional piston engines, the vane engine has a long and constant lever arm, maximizing torque output during combustion and making it highly efficient at lower RPMs.

- 😀 The rotary vane engine increases the combustion surface area during its cycle, which allows for better energy harnessing and greater efficiency than traditional piston or Wankel engines.

- 😀 While the rotary vane engine is theoretically superior, it faces challenges such as centrifugal forces at high RPMs that cause friction and wear, but modern technology like no-contact gas seals could solve this.

Q & A

What is the main problem with traditional piston engines that the rotary vane engine solves?

-Traditional piston engines require a conversion of reciprocation into rotation, which creates vibrations, imbalances, and limits maximum RPM. The rotary vane engine, by contrast, is based on pure rotation, eliminating the need for these conversions, reducing vibrations, and increasing efficiency.

Why did the Wankel rotary engine fail to replace traditional piston engines?

-The Wankel rotary engine failed due to issues with low RPM torque, emissions, fuel economy, and longevity. While it had benefits like a high power-to-weight ratio and smooth operation, it was not efficient in several key areas.

How does the rotary vane engine differ from the Wankel engine in terms of combustion events?

-The rotary vane engine has four combustion events per full 360° rotation of the rotor, whereas the Wankel engine only has one combustion event per rotation of the eccentric shaft, making the vane engine more powerful.

What is the advantage of the rotary vane engine's constant lever arm compared to traditional piston and Wankel engines?

-The rotary vane engine has a constant and long lever arm, which allows for maximum torque output throughout the entire combustion cycle. This results in a broader, more consistent torque curve, especially at low RPMs, compared to the short, fluctuating torque peaks of piston and Wankel engines.

Why is the rotary vane engine considered more efficient than traditional piston and Wankel engines?

-The rotary vane engine increases the surface area during combustion as the vanes extend outward, allowing it to harness more energy from the combustion event. This design improves efficiency by capturing more of the combustion energy, unlike piston and Wankel engines, where energy is often lost as heat.

What are the main mechanical advantages of the rotary vane engine over the piston and Wankel engines?

-The rotary vane engine has fewer moving parts, no reciprocating motion, and no need for components like connecting rods, crankshafts, or cylinder heads. This makes it lighter, more compact, and mechanically simpler than both the piston and Wankel engines.

How does the rotary vane engine's operation resemble that of an electric motor?

-The rotary vane engine operates with pure rotation, similar to an electric motor, which results in zero vibrations, less friction, and fewer moving parts. This contrasts with the more complex motions and vibrations found in piston and Wankel engines.

What challenges does the rotary vane engine face, preventing it from being widely adopted?

-The main challenges include sealing the vanes effectively as the RPM increases, which leads to friction and potential wear. Additionally, centrifugal force can push the vanes outward, increasing friction and reducing longevity. However, advancements like no-contact gas seals and piezoelectric actuators may provide solutions.

How does the rotary vane engine handle low RPM torque compared to the Wankel and piston engines?

-The rotary vane engine excels at producing massive low RPM torque due to its long and constant lever arm, which contrasts with the short torque peaks of piston and Wankel engines. It delivers a broad, sustained torque spike, similar to the performance of an electric motor.

What potential application does the rotary vane engine have outside of automotive use?

-The rotary vane engine is already used in various pump applications, such as in impact guns, espresso machines, and oil pumps. Its design, based on rotary motion, makes it well-suited for fluid handling but requires improved sealing for use as an engine.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

CARA MESIN ROTARY BEKERJA | Wankel Engine

Poisoning AI with ".аss" subtitles

Inversions of Single Slider crank Mechanism in Tamil #tom #kom #mechanism

【新車】トヨタの力を借りてマツダが新型車【3rotor ICONIC SP】を出す可能性が出てきました。

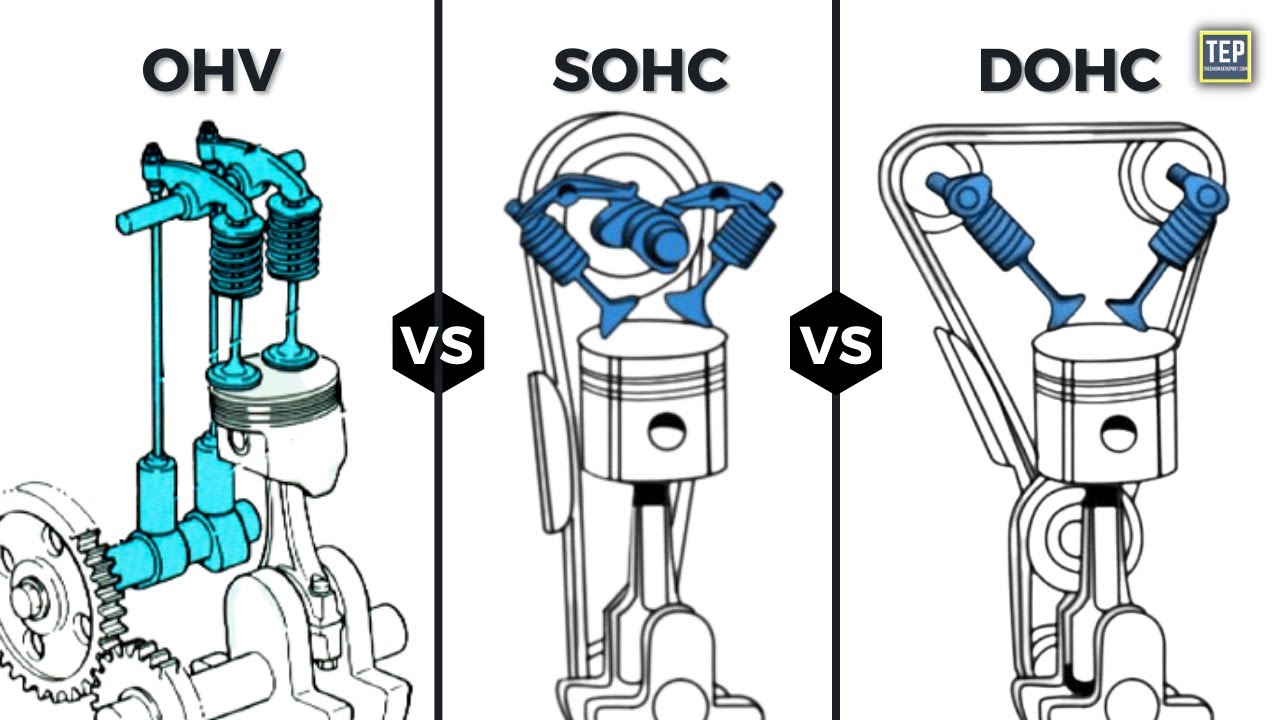

Which is the Best Engine Valvetrain Design? OHV, SOHC, DOHC or Flathead | Pros and Cons

6-Stroke Dari Porsche?? Inovasi & Revolusi Mesin Bensin! Cara Kerja Mesin 6-Tak Porsche Dengan 3D

5.0 / 5 (0 votes)