Part. 02 Komunikasi HMI-PLC -PC

Summary

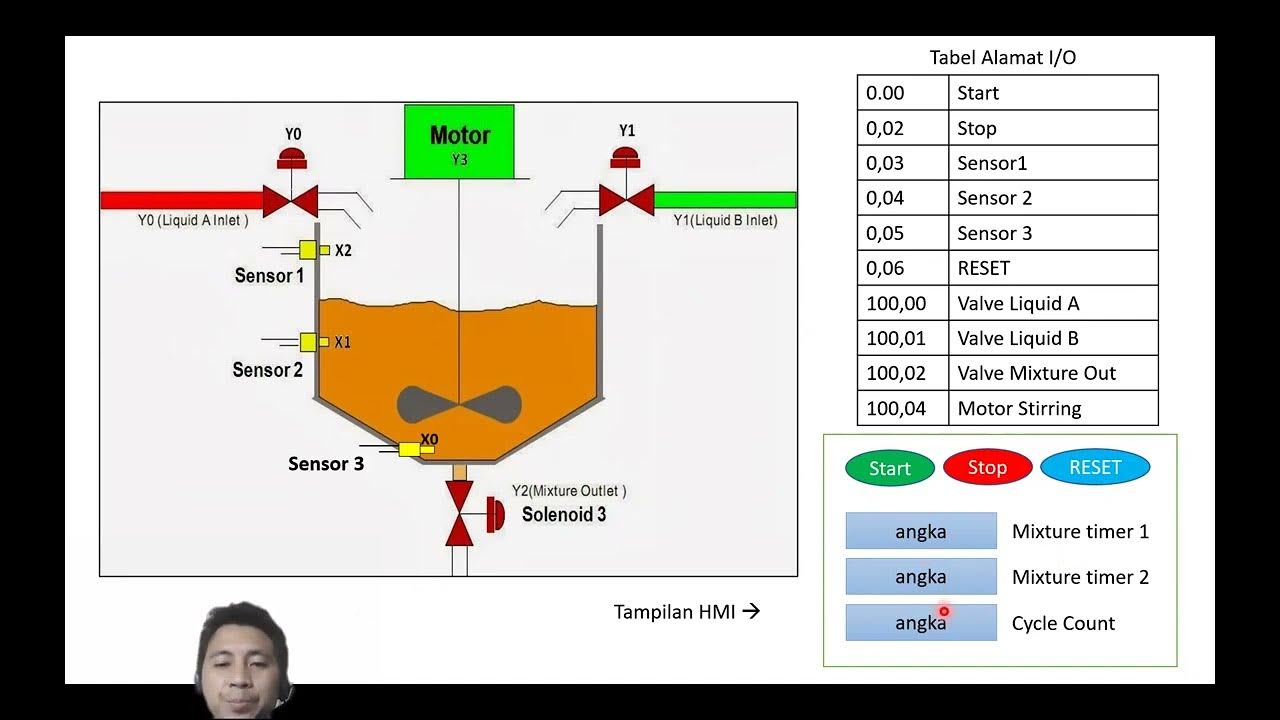

TLDRIn this instructional session, the speaker provides a detailed explanation on how to connect and communicate between HMI, PC, and PLC systems in an automation setup. The lesson covers the necessary hardware components, such as Ethernet, RS-232, and USB cables, and details how each device interacts, from transferring programs to displaying HMI designs. The importance of proper IP address configuration for seamless data communication is also highlighted. This session aims to equip learners with the knowledge to set up and troubleshoot an automation system for effective operation.

Takeaways

- 😀 The lesson begins with a prayer and a focus on the importance of the learning process, asking for blessings and guidance.

- 😀 The main topic of the session is the structure of cable connections between HMI, PC, and PLC, and how to communicate between these devices.

- 😀 The setup involves an HMI, a PC/laptop for program creation, and a PLC for controlling automation systems.

- 😀 Communication between the HMI and PLC uses RS-232 cables, while a modem connects the HMI and PC via Ethernet cables.

- 😀 PLC programs can be transferred via USB cables, and HMI design programs can be transferred using wireless connections between the laptop and the modem.

- 😀 The PLC in the example is a CP1N-20DRA model, which connects to a 240V AC power source.

- 😀 The HMI in use is a Wintech MT87 IP model, and communication between HMI and PLC is done using RS-232 cables with specified pin configurations.

- 😀 The serial port RS-232 configuration includes specific pin assignments for data transmission (TX), data reception (RX), and grounding.

- 😀 The system uses three types of cables: modem cables, USB cables, and RS-232 cables to establish the communication network between devices.

- 😀 IP addressing is crucial for device communication, with specific addresses set for the laptop, modem, and HMI to ensure clear identification and avoid conflicts in the network.

Q & A

What is the main topic of the lesson in the video?

-The main topic is about the connection structure and communication between HMI (Human-Machine Interface), PC, and PLC (Programmable Logic Controller) in an automation system.

What is the purpose of the HMI in the system?

-The HMI is used to provide a user interface for interacting with the PLC, allowing for programming and monitoring of the automation system.

How are the devices connected for communication?

-The devices are connected using various cables: Ethernet cable for the modem to HMI connection, RS232 cable for communication between the HMI and PLC, and USB cable for transferring PLC programs.

What types of communication cables are mentioned in the lesson?

-The lesson mentions three types of cables: Ethernet cables, RS232 cables, and USB cables.

What type of PLC is being used in the system?

-The PLC being used is a CP1N-20DRA model.

What is the significance of setting IP addresses in the system?

-Setting IP addresses is important to ensure that each device, such as the laptop, modem, and HMI, can communicate without conflicts and direct the data to the correct device.

What IP address is assigned to the laptop?

-The IP address assigned to the laptop is 192.168.1.x, where 'x' can be chosen to avoid conflicts in the network.

What IP address is assigned to the modem?

-The modem is assigned the IP address 192.168.2.x.

How does the data transfer from the laptop to the HMI?

-The data from the laptop to the HMI is transferred wirelessly via a modem, using a Wi-Fi connection to communicate with the HMI.

What is the role of the RS232 cable in the system?

-The RS232 cable is used for direct communication between the HMI and PLC, enabling data transfer and control signals between these devices.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Penjelasan Tugas Kelompok

Digital Product Modelling and Sorting System Visualisation

Optix Basics: Out of Box Setup & Hardware Review

Automation engineer कैसे बने ? After Mechanical, Electrical & ECE engg.| High salary engineering Job

Repair Broken Shortcuts in FTView Studio Machine Edition

mengenal plc dan contoh sederhana dengan zelio 3

5.0 / 5 (0 votes)