LOAD TESTING WELDING POWER SOURCES

Summary

TLDRThis video demonstrates the process of performing resistance load testing on a welding power source to ensure it meets desired specifications. The testing procedure includes five key steps: checking primary line voltage, measuring open circuit voltage, verifying power source output at rated load, testing minimum and maximum voltage ranges, and examining remote and other controls. Using an SRH-33 constant current power source and a load bank, the video walks through each step to ensure the machine operates within the required parameters, confirming the power source is ready for service.

Takeaways

- 😀 Resistance load testing ensures that a welding power source is performing to the desired specifications.

- 😀 The testing procedure involves five steps: checking primary line voltage, measuring open circuit voltage, testing at rated load, verifying minimum and maximum ranges, and checking remote and other controls.

- 😀 The first step is to check the primary line voltage on a three-phase machine, verifying all three phases.

- 😀 The second step is to measure the open circuit voltage using a load bank and compare it with the power source specifications.

- 😀 The open circuit voltage should match the service manual's specifications. In this case, 79 volts was acceptable compared to the specified 75 volts.

- 😀 The third step involves testing the power source at rated load, ensuring it delivers the correct output (300 amps at 32 load volts).

- 😀 Adjusting the load using course and fine selector switches ensures the voltage drops to the specified level (32 volts), and the amperage output is within specifications.

- 😀 Step four checks the minimum and maximum of each range by adjusting the load bank to the required test points (e.g., 36 volts for high range and 28 volts for low range).

- 😀 In the high range, the amperage reading should be around 375 amps; in this case, 380 amps was measured.

- 😀 The last step involves verifying the remote control and other controls. The remote control must adjust the current appropriately when set to maximum.

- 😀 Once all tests are performed and specifications are met, the power source can be returned to service.

Q & A

What is the purpose of resistance load testing?

-Resistance load testing is used to ensure that a welding power source is performing according to the desired specifications, verifying its functionality and performance.

What type of power source is demonstrated in the testing procedure?

-The testing procedure uses an SRH-33 constant current power source, although the load bank can be used to test any welding power source.

What are the five steps involved in the load testing process?

-The five steps in the load testing process are: 1) checking the primary line voltage, 2) measuring the open circuit voltage, 3) checking the power source at rated load, 4) testing the minimum and maximum of each range, and 5) verifying remote and other controls.

How is the primary line voltage checked during the load test?

-The primary line voltage is checked by measuring the voltage across all three phases of the three-phase machine, starting with any two lines, then checking the other two phases.

What is measured during the second step of the load testing procedure?

-During the second step, the open circuit voltage is measured. The load bank is connected to the power source, and the open circuit voltage is compared with the specifications in the service manual.

What does the open circuit voltage measurement indicate about the power source?

-The open circuit voltage measurement helps verify whether the power source is operating within the correct voltage range. For instance, if the specifications call for 75 volts and the load bank measures 79 volts, the open circuit voltage is acceptable.

What is tested in the third step of the procedure?

-In the third step, the power source is tested at rated load. The power source is set to 300 amps, and the load voltage is adjusted to drop to 32 volts, ensuring that the amperage output matches the rated load specifications.

How are the minimum and maximum ranges tested during the procedure?

-The minimum and maximum ranges are checked by setting the control to the maximum output and adjusting the load bank to reach the specified voltage values. Then, amperage is measured to verify if it falls within the required specifications.

What is the significance of the load voltage values of 36V and 28V in the testing?

-The load voltage values of 36V and 28V correspond to the high and low ranges of the power source, respectively. These values are used to ensure that the amperage is within the expected limits when the power source is operating at different voltage ranges.

How is the functionality of remote controls tested?

-The remote control is tested by setting it to maximum and adjusting the power source and load bank for a rated load test. A drop in current during this process confirms that the remote control is functioning properly.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

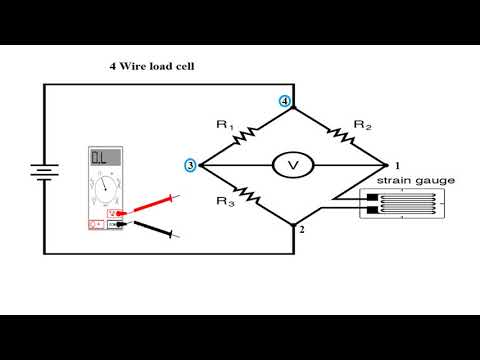

How to test a load cell

JMeter Load Testing | Load Testing Using JMmeter | JMeter Tutorial For Beginners | Simplilearn

Processos de Fabricacao - Soldagem por resistência

CH02. L02. Test-types

How to Test a Load Cell with a Multimeter

Telecurso 2000 Processos de Fabricação 14 O arco elétrico entra em ação

5.0 / 5 (0 votes)