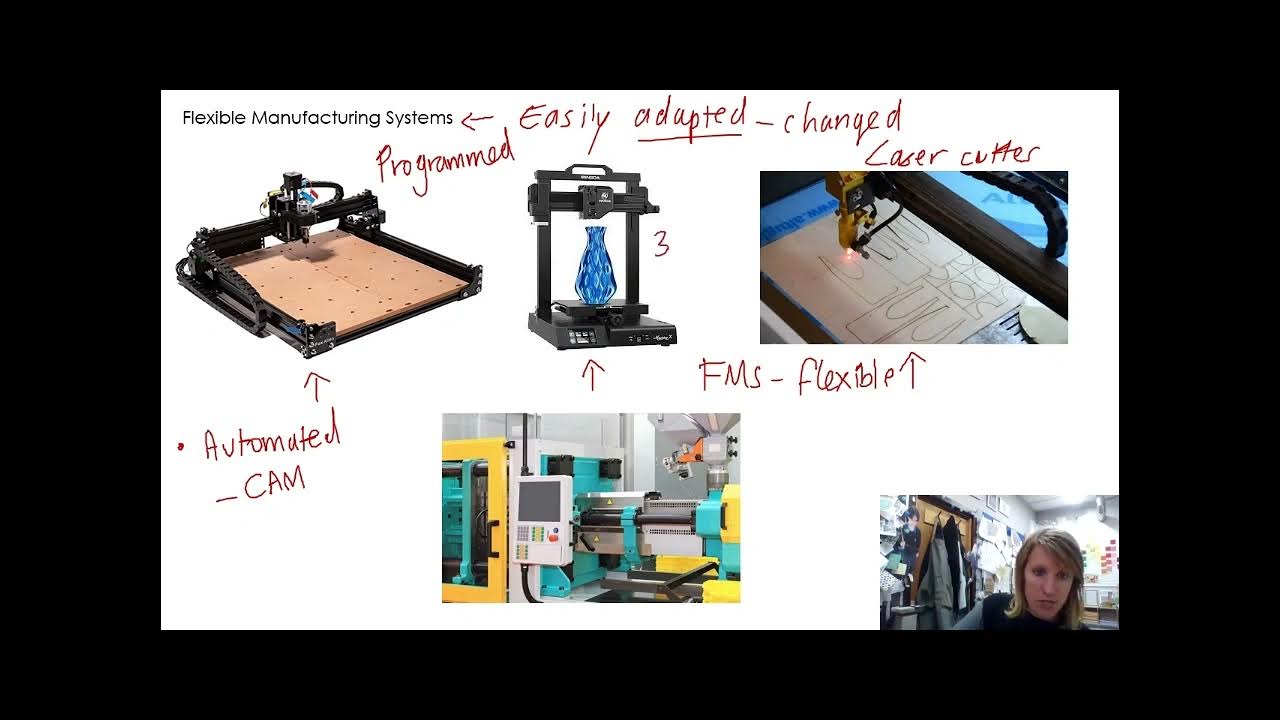

Flexible Manufacturing Systems | FMS | Industrial Automation

Summary

TLDRThis video provides an in-depth explanation of Flexible Manufacturing Systems (FMS), exploring their components, capabilities, and advantages. It highlights FMS's ability to produce a variety of parts, adapt to schedule changes, recover from errors, and introduce new part designs. The system is controlled by a supervisory control system with distributed controllers, ensuring smooth operations. The video also discusses real-world applications, such as Wright Aerospace’s FMS used for manufacturing 600 different aircraft components. This system showcases the versatility of FMS, including its ability to produce both batch and single parts in continuous mode.

Takeaways

- 😀 FMS (Flexible Manufacturing System) is the most advanced form of group technology, combining automated workstations and material handling systems in machine cells.

- 😀 A supervisory control system coordinates all distributed controllers, managing the entire operation of the FMS.

- 😀 FMS offers flexibility by enabling the production of soft variety parts, but this variety does have limits.

- 😀 The ability of FMS to change its setup—such as tools and fixtures—allows it to adapt to different parts and operational sequences.

- 😀 There are four critical tests to determine if a system qualifies as 'flexible': Part variety, schedule change, error recovery, and the ability to integrate new parts.

- 😀 Part variety test: FMS should handle various parts but within defined limits (soft variety).

- 😀 Schedule change test: FMS must accept changes in production schedules, part mix, or quantities without disruption.

- 😀 Error recovery test: FMS should recover from malfunctions or breakdowns smoothly, ensuring continuous production.

- 😀 New part test: FMS must be capable of integrating new part designs into the production mix and making design changes easily.

- 😀 FMS systems can range from simple single machine cells to complex systems with multiple workstations and non-processing stations (e.g., washing or inspection).

- 😀 A real-world example of FMS is at WOT Aerospace in Dallas, Texas, where an FMS machines 600 different aircraft components using automated guided vehicles and CNC machine centers.

Q & A

What is Group Technology, and how does it relate to Flexible Manufacturing Systems (FMS)?

-Group Technology (GT) refers to the practice of grouping similar parts based on their design and manufacturing characteristics to streamline production. FMS is an advanced form of GT, where automated systems are used to handle various parts within a flexible environment, allowing for efficient, adaptable manufacturing processes.

What is a Flexible Manufacturing System (FMS)?

-An FMS is a manufacturing system that consists of automated workstations grouped into a machine cell, with fully automated material handling. It is controlled by a supervisory system, which oversees the operation of distributed controllers, ensuring flexibility in production.

How does an FMS handle varying types of parts?

-An FMS can handle a variety of parts by identifying incoming raw materials or parts and adjusting its operational instructions and sequence accordingly. This capability allows it to produce different parts based on input data and change its physical setup as needed.

What is the concept of 'soft variety' in FMS, and how is it different from 'hard variety'?

-Soft variety refers to the ability of an FMS to produce a wide range of parts with minor adjustments, whereas hard variety involves producing significantly different parts, which requires more complex and rigid systems. FMS can handle soft variety but has limitations with hard variety.

What are the four tests required for a system to be considered flexible in an FMS?

-The four tests are: (1) Part variety test, which checks if the system can produce various parts; (2) Schedule change test, which evaluates the system's adaptability to changes in production schedules; (3) Error recovery test, which ensures the system can recover from malfunctions; and (4) New part test, which checks if new part designs can be integrated into the system.

How does FMS adapt to schedule changes in production?

-FMS can readily accept changes in production schedules, part mix, or production quantities. This adaptability is critical for maintaining flexibility and ensuring that production goals are met even when changes occur in the manufacturing process.

What role do distributed controllers play in an FMS?

-Distributed controllers are specialized controllers that manage different portions of the FMS. They are responsible for controlling specific tasks or workstations, while the supervisory controller oversees and coordinates the entire system, ensuring efficient operation.

What are the three forms of flexible manufacturing systems mentioned in the transcript?

-The three forms of flexible manufacturing are: (1) A single machine cell, which consists of one machine capable of multiple operations; (2) A flexible manufacturing cell with two or three workstations that work automatically and in sync; and (3) A full FMS with multiple workstations and non-processing stations for support tasks.

What is the significance of non-processing workstations in a large FMS?

-Non-processing workstations in a large FMS do not perform any actual processing but serve supporting functions such as washing, inspection, or other tasks that help maintain the efficiency of the overall system.

Can you give an example of FMS use in an industry as mentioned in the transcript?

-One example is the FMS at What Aerospace in Dallas, Texas, which machines approximately 600 different aircraft components. It uses eight CNC horizontal machine centers and a fully automated guided vehicle system for part handling, enabling it to produce both batch and single-piece parts.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Video 2 - Flexible and Lean Manufacturing

Akustik Kelautan - Side Scan Sonar

Introduction to Flexible Manufacturing System (FMS)

Group Technology | Industrial Automation

RAMI 4.0: Reference Architecture Model for Industry 4.0 Explained - Industry 4.0 Tutorial [3 of 6]

Materi Pengenalan Pengelasan FCAW, Jurusan Teknik Mesin Harus Tahu ‼️

5.0 / 5 (0 votes)