How a CVT works! (Animation)

Summary

TLDRThis video explains the workings of Continuously Variable Transmissions (CVT), focusing on the variable diameter pulley system. It highlights how pulleys adjust to change the gear ratio, using belts or chains made from rubber, polymer, or steel. The script discusses different mechanisms for power transfer, such as centrifugal force in motor scooters and hydraulic oil pressure in cars. Key components like sheaves, belts, and CVT chains are examined, along with their applications in vehicles. The video provides a clear, accessible explanation of how CVTs function in various vehicles, from scooters to automobiles.

Takeaways

- 😀 CVTs (Continuously Variable Transmissions) use variable diameter pulleys to adjust the gear ratio continuously.

- 😀 The primary mechanism of power transfer in CVTs is through a belt that moves between pulleys, adjusting their distance.

- 😀 When the sheaves (pulleys) are far apart, the pulley functions like a small gear; when close together, it acts like a large gear.

- 😀 The belt must maintain a constant length, requiring simultaneous adjustment of both the input and output pulleys.

- 😀 CVT belts are typically made from rubber, polymer, or steel, with rubber ones often being cogged for better flexibility.

- 😀 Steel belts, composed of multiple steel elements held by bands, can handle up to 300 horsepower in vehicles.

- 😀 A CVT chain consists of rocker pins and plates, which work together to provide a flexible power transfer system.

- 😀 In motor scooters, centrifugal force on the weights of the pulleys helps move the sheaves, adjusting the gear ratio as the scooter accelerates.

- 😀 As scooter speed increases, centrifugal force pushes the weights outward, causing the sheaves to move and change the gear ratio.

- 😀 Modern cars do not use the centrifugal force mechanism for adjusting the sheaves; instead, oil pressure controlled by an oil pump is used.

- 😀 This video is an introduction to CVTs, with additional learning resources available through animations from Learn Engineering or the channel creator.

Q & A

What is the main function of a CVT (Continuously Variable Transmission)?

-A CVT allows for an infinite number of gear ratios, adjusting continuously as the vehicle accelerates or decelerates, providing smoother power delivery compared to traditional transmissions.

How does the variable diameter pulley in a CVT work?

-The variable diameter pulley adjusts the gear ratio by moving its sheaves (the conical parts of the pulley) closer or further apart. When the sheaves are far apart, it behaves like a small gear, and when close together, it acts like a large gear.

What role does the belt play in the operation of a CVT?

-The belt in a CVT transmits power from the input shaft to the output shaft, adjusting its position as the sheaves move to change the gear ratio.

What materials are typically used for CVT belts, and why?

-CVT belts are commonly made from rubber or polymer, often featuring a cogged design to allow for flexibility as the belt adjusts to the variable diameter of the pulleys.

What is the function of a steel belt in a CVT?

-A steel belt in a CVT is made of numerous steel elements held together by thin steel bands, providing durability and strength for higher-powered vehicles (up to 300 horsepower).

How does a CVT chain work?

-A CVT chain consists of rocker pins that connect plates. These plates move together to adjust the gear ratio, enabling the continuous transmission of power.

What mechanism is used in scooters to move the sheaves in a CVT?

-In scooters, centrifugal force is used to move the sheaves. As the scooter accelerates, centrifugal force acts on the weights, pushing them outward, which causes the sheaves to adjust and change the gear ratio.

Why can’t centrifugal force-based CVT mechanisms be used in modern cars?

-Centrifugal force mechanisms, like those used in scooters, are not suitable for modern cars because the forces involved are too small to handle the power demands. Instead, oil pressure is used to adjust the sheaves in automotive CVTs.

How do the sheaves in an automobile CVT move?

-In automobiles, the sheaves are moved using oil pressure supplied by an oil pump. The oil pressure adjusts the position of the sheaves to change the gear ratio.

What are the advantages of using a CVT over traditional transmissions?

-A CVT provides smoother acceleration, better fuel efficiency, and more optimal engine performance by continuously adjusting the gear ratio, unlike traditional transmissions with fixed gears.

Outlines

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowMindmap

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowKeywords

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowHighlights

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowTranscripts

This section is available to paid users only. Please upgrade to access this part.

Upgrade NowBrowse More Related Video

Auto Tech 101: What is a Car Transmission? | Toyota

Comparing Manual Transmission with Automatic & CVT [In Detail]

Почему нет мотоциклов с ВАРИАТОРОМ ?

SERVIS CVT BEAT FI ESP LENGKAP, CARA MEMBERSIHKAN CVT MATIC.

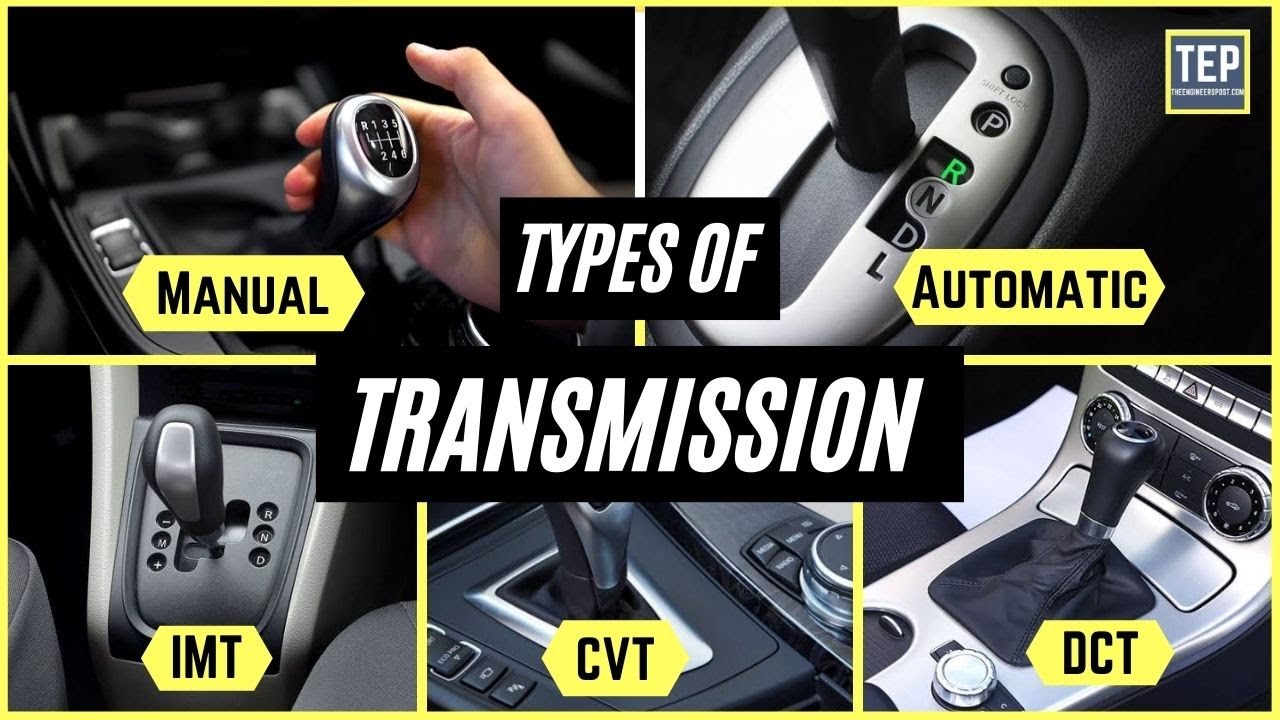

Types of Transmission System (Manual, AT, AMT, iMT, CVT, DCT) Explained

Sistem Kerja CVT Motor Matic Atau Scooter | Cara Kerja CVT (100060.V1)

5.0 / 5 (0 votes)